Magnetron sputtering coating method and system

A magnetron sputtering coating and sputtering cavity technology, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problem of thin film layer, poor film uniformity and stability, display substrate The performance and quality are greatly affected, so as to achieve the effect of stable performance and unaffected film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0036] Embodiments of the present invention provide a magnetron sputtering film coating method and system, which can effectively improve the uniformity of magnetron sputtering film formation, thereby ensuring the performance and quality of a display substrate.

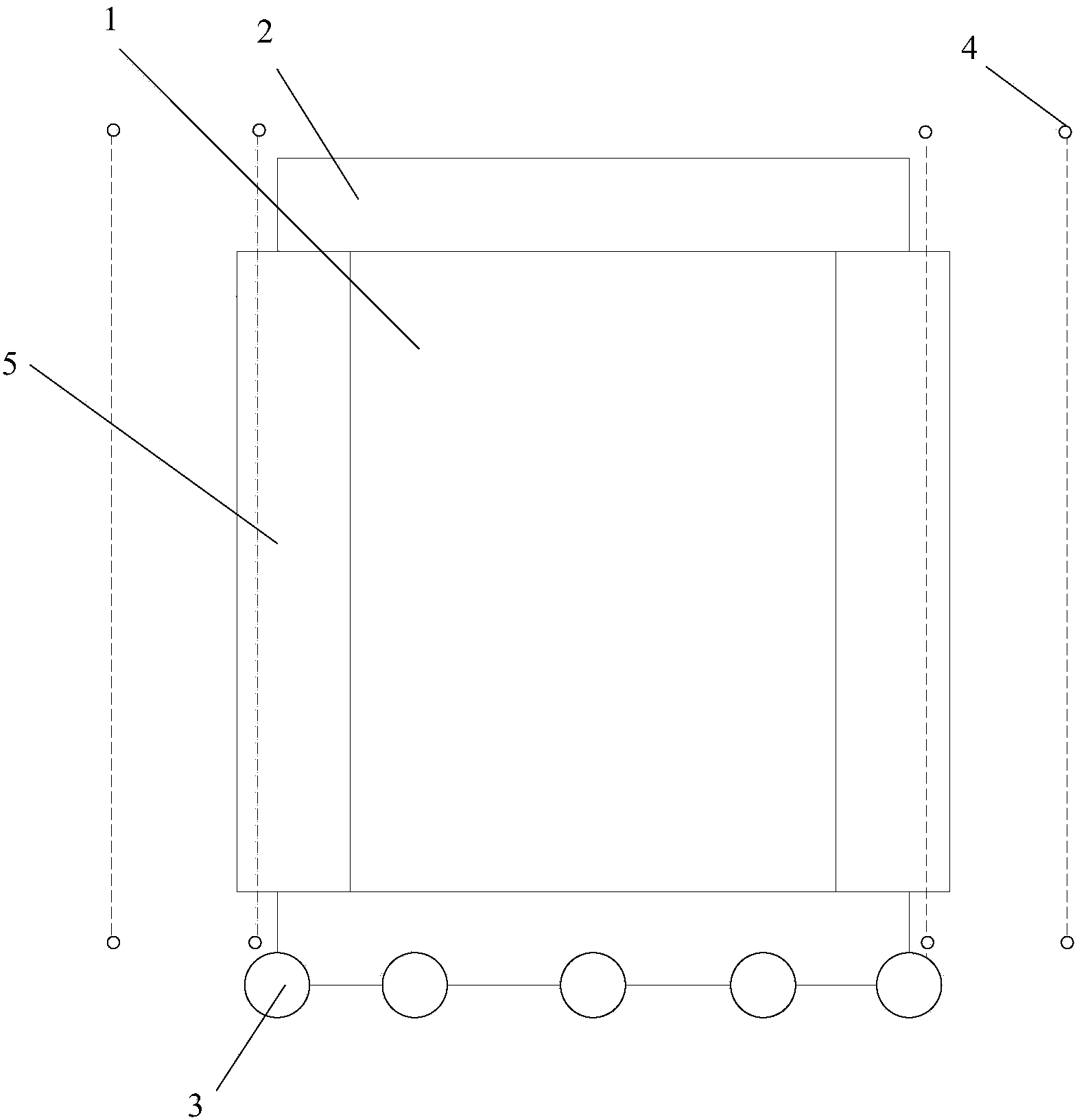

[0037] An embodiment of the present invention provides a magnetron sputtering coating system, including a sputtering chamber, and also includes:

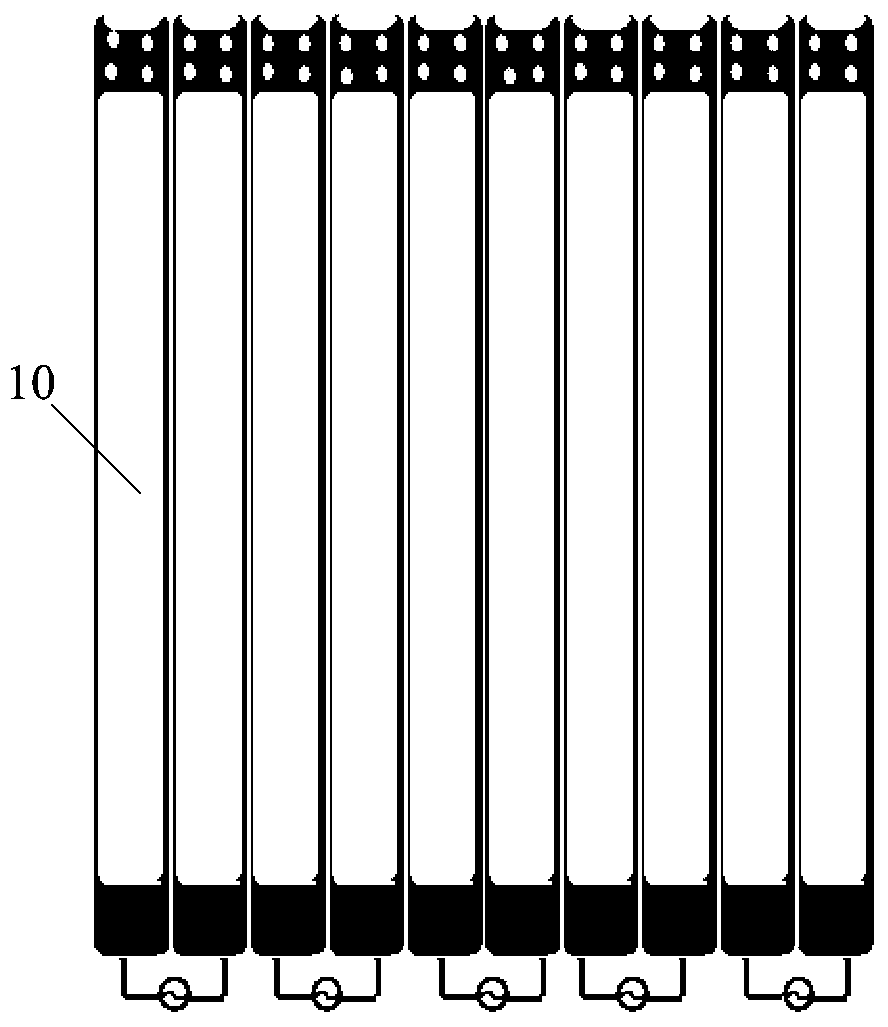

[0038] A target group formed by splicing multiple targets;

[0039] a substrate carrier arranged opposite to the target group and used to carry the substrate to be film-formed;

[0040] A transmission device that drives the substrate carrier to reciprocate along the direction in which the targets are arranged.

[0041] In this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com