Storage and transfer trolley for automobile sliding column assemblies

A transfer vehicle and sled technology, applied in trolleys, motor vehicles, multi-axle trolleys, etc., can solve problems such as control of production efficiency and quality, cost input, waste of resources, and inflexible use methods, and achieve convenient loading and unloading. The effect of sliding column assembly, simple production scheme, and easy replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention will be further described:

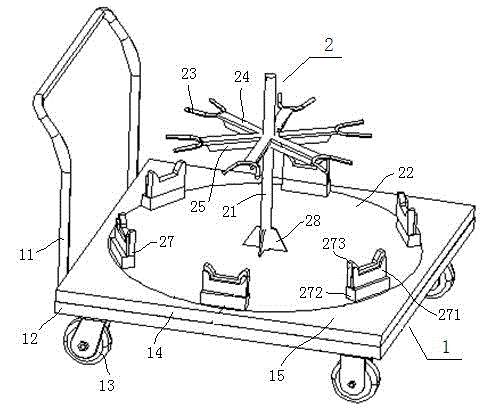

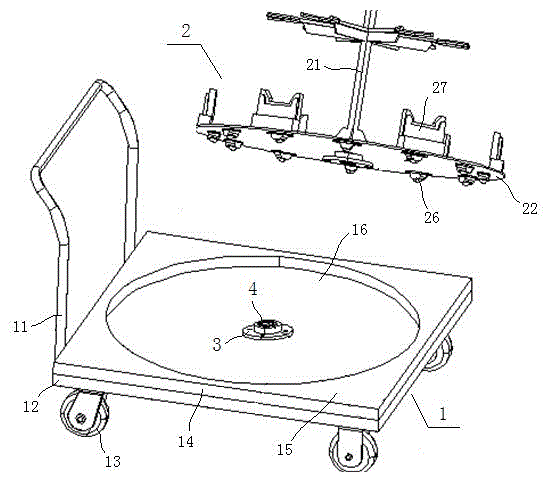

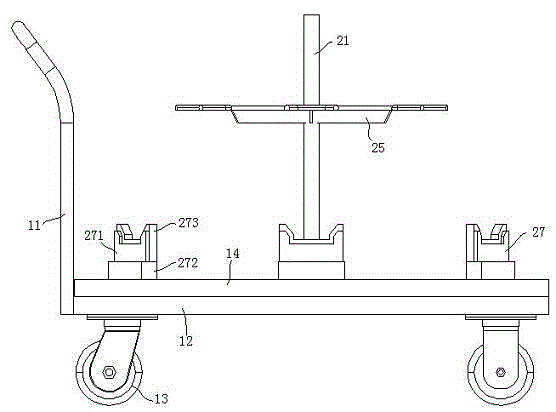

[0033] Figure 1 to Figure 6 Shown is a storage and transfer vehicle for automobile strut assemblies, including a trolley 1 and a storage rack 2 disposed on the trolley 1 , and the storage rack 2 is rotatably disposed on the trolley 1 through a bearing support 3 and a bearing 4 .

[0034] The dolly 1 includes an armrest 11 , a bottom frame 12 , a bottom frame panel 16 arranged on the bottom frame 12 , wheels 13 , an upper auxiliary frame 14 and an upper panel 15 arranged on the upper auxiliary frame 14 . The handrail 11 is made of a round pipe, and is welded and fixed on the edge of the bottom frame 12 to provide a control point for pushing the trolley 1 . The bottom frame 12 adopts square tubes to be welded into a frame structure, and the bottom frame panel 16 covers the frame structure and the bottom frame 12 together supports the storage rack 2 . Wheel 13 is a shock-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com