Repair method of connecting lug

A repair method and technology for connecting ears, applied in welding equipment, workpiece edge parts, metal processing equipment, etc., can solve problems such as deformation and distortion of connecting ears, insufficient strength and rigidity, and increased labor intensity, achieving less maintenance and serious solutions. Deformation and fracture, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

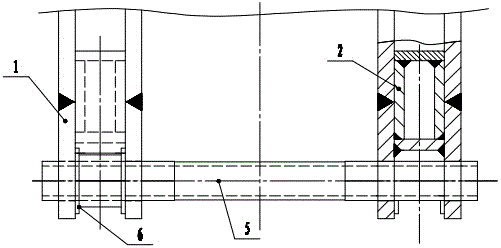

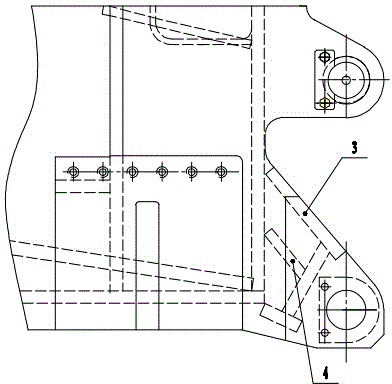

[0016] like Figure 1~2 As shown, a method for repairing a connection ear is characterized in that it includes a connection ear 1, a sticking plate 2, a reinforcement plate 3, a rib plate 4, a process shaft 5 and a distance pad 6, and includes the following steps:

[0017] (1) Flatten the fracture surface of the broken connecting ear 1, process the welding groove, and process the welding positions on the veneer 2, reinforcement plate 3 and rib plate 4 into grooves;

[0018] (2) Use the finished connecting ear 1 as a template to improve the accuracy of the welding position, and mark the welding position of the broken part of the connecting ear 1 on the body, so as to facilitate welding the positions of the pasting plate 2, reinforcement plate 3 and rib plate 4;

[0019] (3) Pass the process shaft 5 through the left and right ears, insert the broken connecting ear 1 and two plates on the two ends of the process shaft 5 respectively, and insert the distance pad 6 between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com