Full-automatic laser welding method and full-automatic laser welding device

A laser welding, fully automatic technology, used in laser welding equipment, welding equipment, metal processing equipment and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

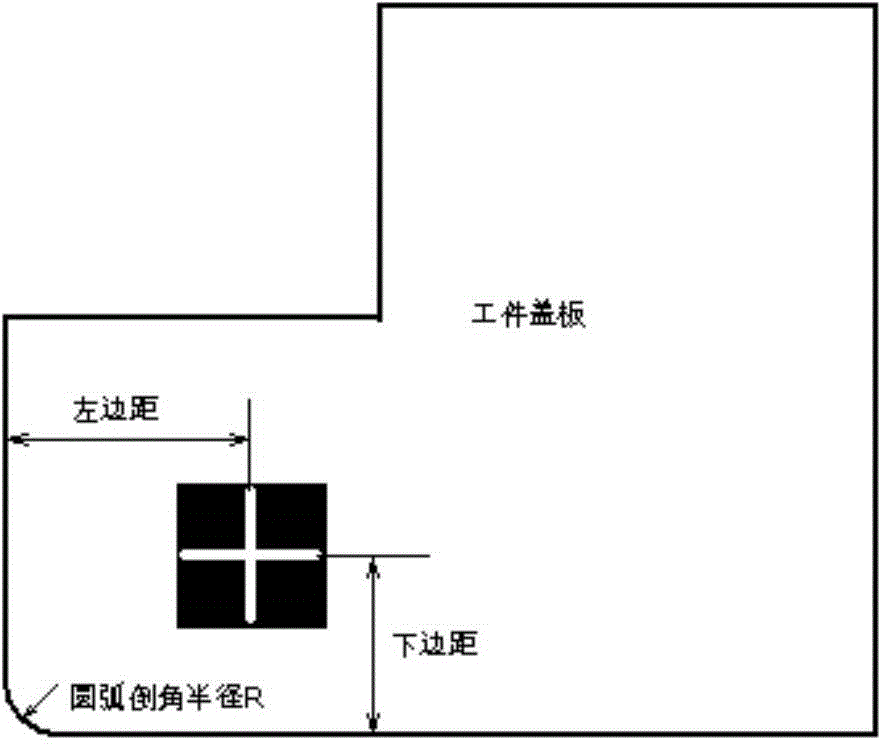

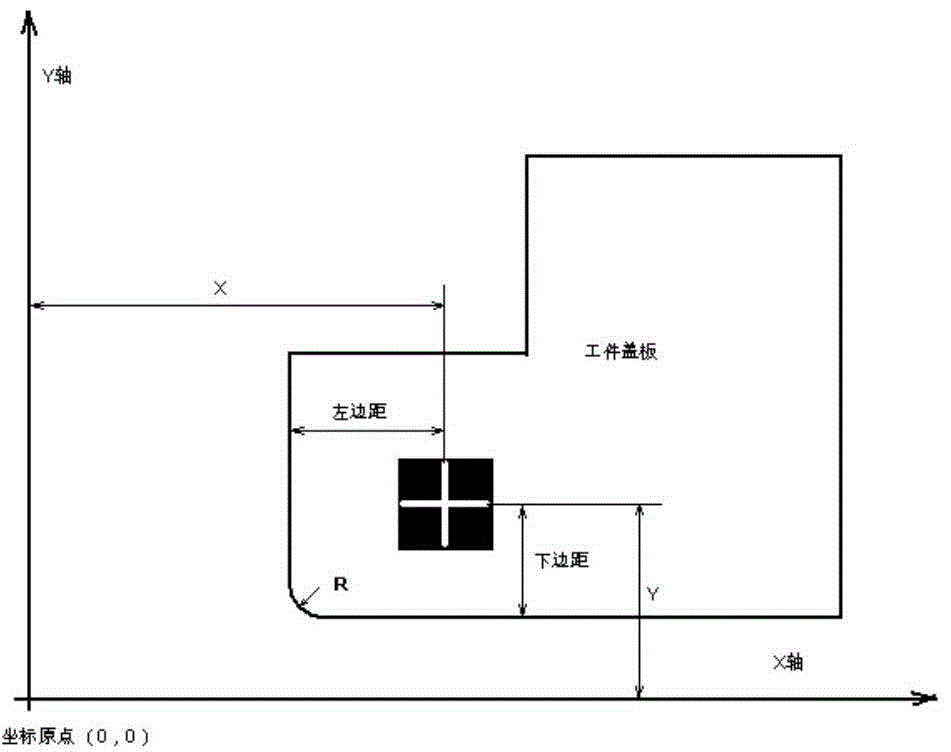

[0033] Describe the present invention below in conjunction with specific embodiment:

[0034] The device used in the present invention includes: a glove box, an XY motion platform, a servo motor, a servo driver, a motion controller, an industrial camera, a light source, an optical platform, a computer, and the like. The glove box provides the environment required for laser welding. The XY motion platform, servo motor, servo drive, and motion controller realize the precise movement and control of the mechanism. The optical platform is used to place the workpiece, and the industrial camera and light source are used for image lighting and acquisition. The rangefinder is used to measure the height of the welding surface, and the computer is used for software control and coordination of software and hardware resources.

[0035] The specific implementation steps are:

[0036] Step 1: Preparation Phase:

[0037] (1) Coding: According to the specific form of the trajectory informati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com