Traditional Chinese medicine extract product for treating chloasma and preparation method for traditional Chinese medicine extract product

The technology of extract and chloasma, applied in the field of medicine, can solve the problems such as undiscovered winter mulberry leaf extract, little research on treatment or health care, etc., and achieves the effect of significant medicinal effect, high utilization, and elimination of pigmentation deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

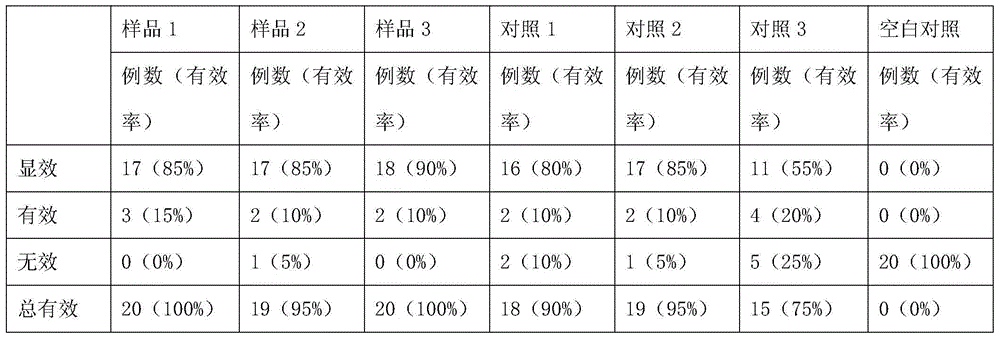

Examples

Embodiment 1

[0076] Embodiment 1: extract preparation

[0077] 1) Winter mulberry leaf extract: Take winter mulberry leaves, remove impurities, add 8 times the amount of water to reflux and extract twice, each time for 2 hours, filter, combine the filtrates, concentrate under reduced pressure to form a thick paste, then add 4 times the amount of 75% Ethanol, fully stirred evenly, left standing for 24 hours, filtered, the filtrate was decompressed to recover ethanol, and concentrated into a thick paste with a relative density of 1.20 at 60°C, to obtain the winter mulberry leaf extract;

[0078] 2) Peony seed oil: peeled and dried peony seeds, crushed into 80 meshes, added petroleum ether with a boiling range of 60-90°C, the liquid-to-solid ratio of the petroleum ether and peony seeds was 9ml / g, and mixed well Then put it into an ultrasonic processor, adjust the power to 250W, and the temperature is 50°C. After ultrasonic treatment for 30 minutes, separate the solvent mixture and residue, re...

Embodiment 2

[0079] Embodiment 2: extract preparation

[0080] 1) Winter mulberry leaf extract: Take winter mulberry leaves, remove impurities, add 6 times the amount of water to reflux and extract 3 times, each time for 1 hour, filter, combine the filtrates, concentrate under reduced pressure to form a thick paste, then add 5 times the amount of 60% Ethanol, fully stirred evenly, allowed to stand for 18 hours, filtered, and the filtrate was decompressed to recover ethanol, and concentrated into a thick paste with a relative density of 1.10 at 60°C to obtain the winter mulberry leaf extract;

[0081] 2) Peony seed oil: shelled and dried peony seeds, crushed into 60 meshes, added petroleum ether with a boiling range of 60-90°C, the liquid-to-solid ratio of the petroleum ether and peony seeds was 10ml / g, and mixed well Then put it into an ultrasonic processor, adjust the power to 200W, and the temperature is 60°C. After ultrasonic treatment for 20 minutes, separate the solvent mixture and re...

Embodiment 3

[0082] Embodiment 3: extract preparation

[0083] 1) Winter mulberry leaf extract: Take winter mulberry leaves, remove impurities, add 10 times the amount of water to reflux for extraction for 3 hours, filter, combine the filtrate, concentrate under reduced pressure to form a thick paste, then add 3 times the amount of 85% ethanol, and stir well , stand still for 12 hours, filter, and recover ethanol from the filtrate under reduced pressure, and concentrate it into a thick paste with a relative density of 1.30 at 60°C to obtain the winter mulberry leaf extract;

[0084] 2) Peony seed oil: shelled and dried peony seeds, crushed into 100 meshes, added petroleum ether with a boiling range of 60-90°C, the liquid-to-solid ratio of the petroleum ether and peony seeds was 5ml / g, and mixed evenly Then put it into an ultrasonic processor, adjust the power to 300W, and the temperature is 40°C. After ultrasonic treatment for 40 minutes, separate the solvent mixture and residue, recover p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com