Bread premixed flour and preparation method thereof

A technology of ready-mixed powder and bread, which is applied in the food field, can solve problems such as difficult success and complicated operation, and achieve the effect of safe success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

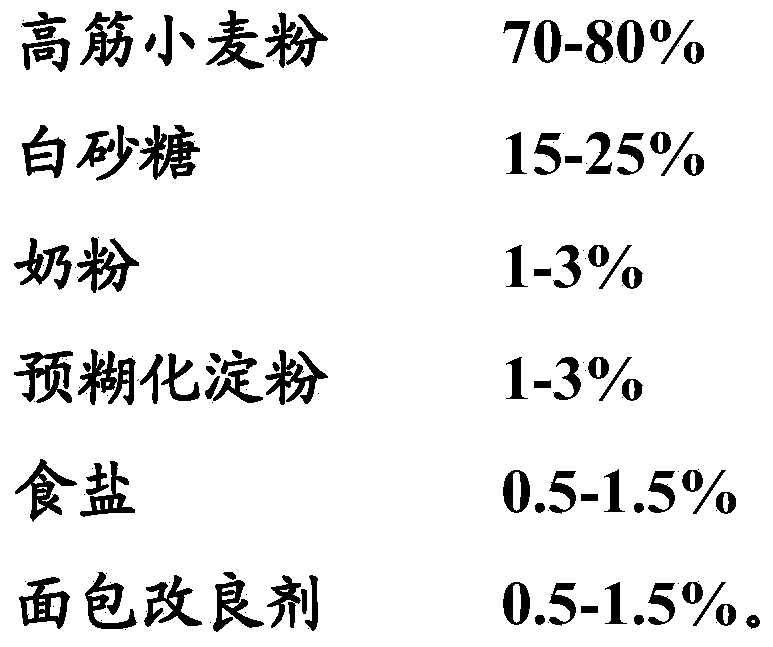

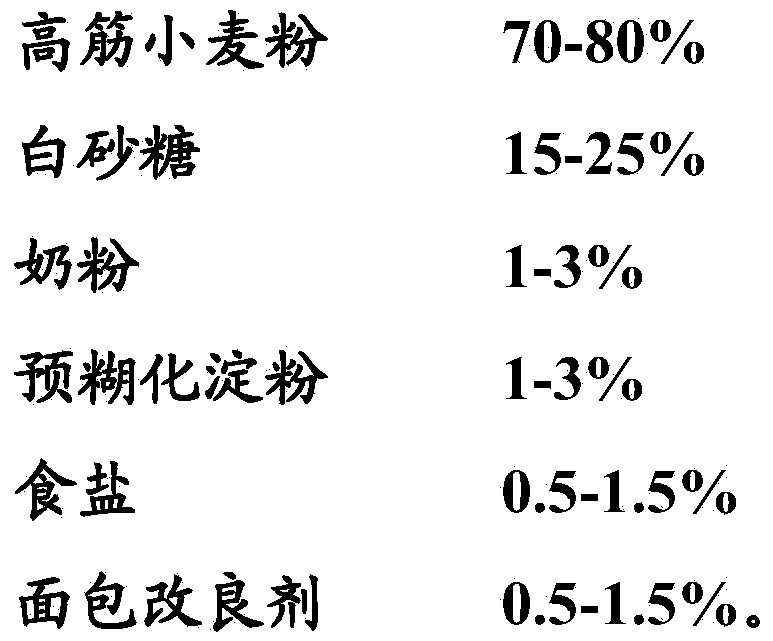

Method used

Image

Examples

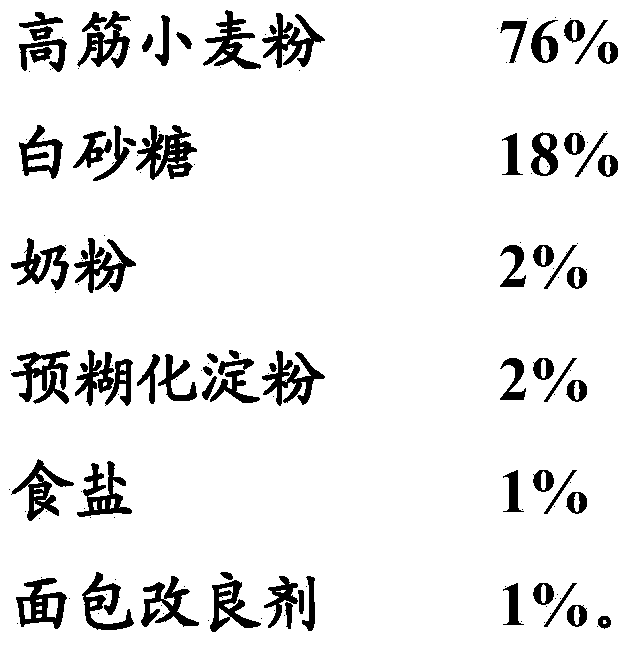

Embodiment 1

[0063] Weigh 760g of high-gluten wheat flour (Shandong Shengqi Biological Co., Ltd.), 180g of white granulated sugar (super pure granulated sugar, Beijing Gusong Economic and Trade Co., Ltd.), 20g of milk powder, 20g of pregelatinized starch (Guangxi Longan Yinfeng Starch Co., Ltd.), 10g of salt , bread improver (Shengqi HB1000 bread improver, Shandong Shengqi Biological Co., Ltd.) 10g mixes, stirs evenly in the mixing mixer (SYJW horizontal paddle mixer, Shanghai Shenyin Machinery Group Co., Ltd.) to obtain bread ready-mixed Powder 1kg. All the above components were pulverized by a pulverizer (SF-400 stainless steel pulverizer, Guangzhou Daxiang Electronic Machinery Equipment Co., Ltd.) before weighing to a particle size below 30 mesh.

[0064] Put the obtained bread premix powder into the mixing tank, then add 200g of water and 1.4kg of whole egg liquid, and stir for 3 minutes at 10rpm. During the mixing process, pay attention to scraping the sides and bottom of the tank to ...

Embodiment 2

[0070] Take high-gluten wheat flour (same as Example 1) 734g, white granulated sugar (same as Example 1) 220g, milk powder 16g, pregelatinized starch (same as Example 1) 14g, salt 8g, bread improver (same as Example 1) 8g mixes, stirs in mixing mixer (with embodiment 1), obtains bread premix 1kg. Each of the above components was pulverized by a pulverizer (same as in Example 1) before being weighed until the particle size was below 30 mesh.

[0071] Put the obtained bread premix powder into a mixing tank, then add 200g of water and 1.5kg of whole egg liquid, and stir for 3 minutes at a speed of 15rpm. During the mixing process, pay attention to scraping the sides and bottom of the tank to prevent the material from sinking to the bottom.

[0072] Keep the stirring speed at 15rpm, add corn salad oil at a flow rate of 7ml / s and stir evenly.

[0073] Pour the bread batter into a 50cm×50cm baking tray, and bake at 160°C on upper heat and 140°C on lower heat for 30 minutes until co...

Embodiment 3

[0077] Take high-gluten wheat flour (same as Example 1) 764g, white granulated sugar (same as Example 1) 160g, milk powder 25g, pregelatinized starch (same as Example 1) 25g, salt 13g, bread improver (same as Example 1) 13g mixes, stirs in mixing mixer (with embodiment 1), obtains bread premix 1kg. Each of the above components was pulverized by a pulverizer (same as in Example 1) before being weighed until the particle size was below 30 mesh.

[0078] Put the obtained bread premix powder into the mixing tank, then add 200g of water and 1.4kg of whole egg liquid, and stir for 3 minutes at a speed of 20rpm. During the mixing process, pay attention to scraping the sides and bottom of the tank to prevent the material from sinking to the bottom.

[0079] Keep the stirring speed at 20rpm, add soybean salad oil at a flow rate of 10ml / s and stir evenly.

[0080] Pour the bread batter into a 50cm×50cm baking tray, and bake at 170°C on upper heat and 150°C on lower heat for 25 minutes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com