Device with pulverized coal separator between coal mill and burner

A separator and coal mill technology, which is applied in the fields of devices, boilers, and utility boilers with pulverized coal separators, can solve the problems of low safety factor, insufficient combustion, unstable ignition and combustion, etc., and achieve excellent installation and use environment. , Conducive to installation and use, maintenance and repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

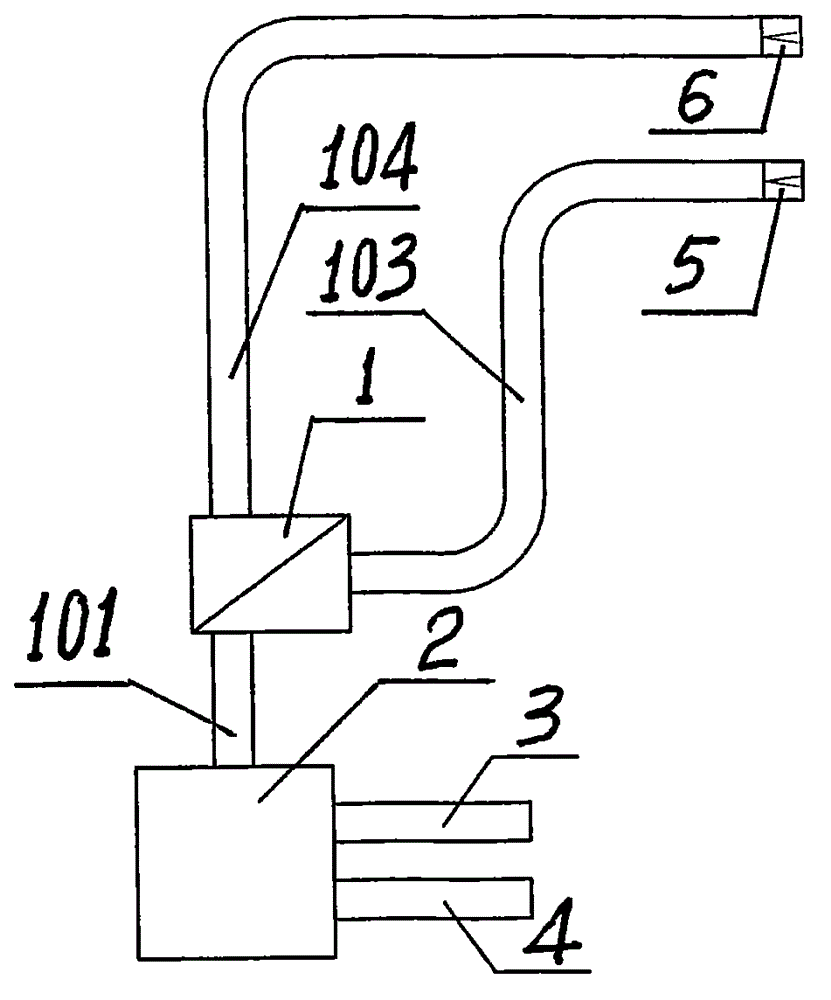

[0036] The "device for setting a pulverized coal separator between the coal mill and the burner" of the present invention will be described in detail below in conjunction with the accompanying drawings. As attached to the manual figure 1 , 2 , 4, 5, and 6 show:

[0037] A device for setting a pulverized coal separator between a coal mill and a burner, the separator consisting of a mixing tube 101, a separating tube 102, a concentrated pulverized coal tube 103, a thin pulverized coal tube 104, an adjusting shaft 105, and a separating plate 106 1 and coal mill 2, air pipe 3, coal pipe 4, thick burner nozzle 5, and light burner nozzle 6;

[0038] A pulverized coal separator device is arranged between the coal mill and the burner, and its mixing pipe 101 and separation pipe 102, separation pipe 102, thick pulverized coal pipe 103 and light pulverized coal pipe 104 are all fixedly connected, and its separation pipe 102 It is connected with the adjustment shaft 105 in a rotating ...

specific Embodiment approach 2

[0044] Carry out by specific embodiment one, just: just as specification attached figure 2 , 6 As shown, the thick pulverized coal pipe 103 and the light pulverized coal pipe 104 are implemented in parallel with each other at a position between the two; the expected good effect is also obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com