Automatic plate-turning door synchronously controlled by double direct current brushless motors

A DC brushless motor and brushless motor technology, applied in door/window accessories, power control mechanism, wing fan control mechanism, etc., can solve the problem that the place with beautiful appearance is not suitable for use, occupies space, and has limited space, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described below in conjunction with accompanying drawing.

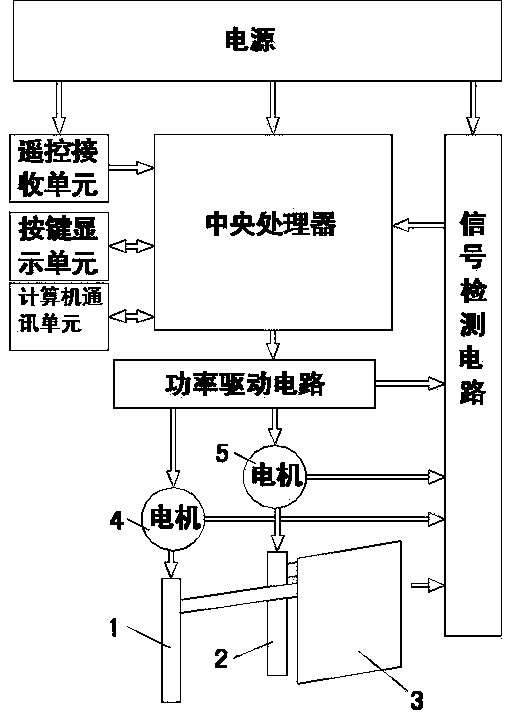

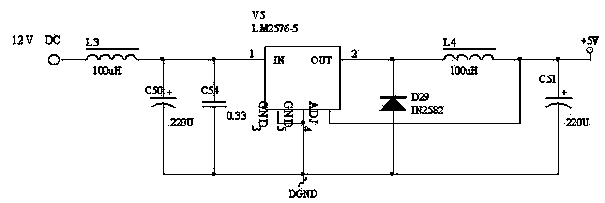

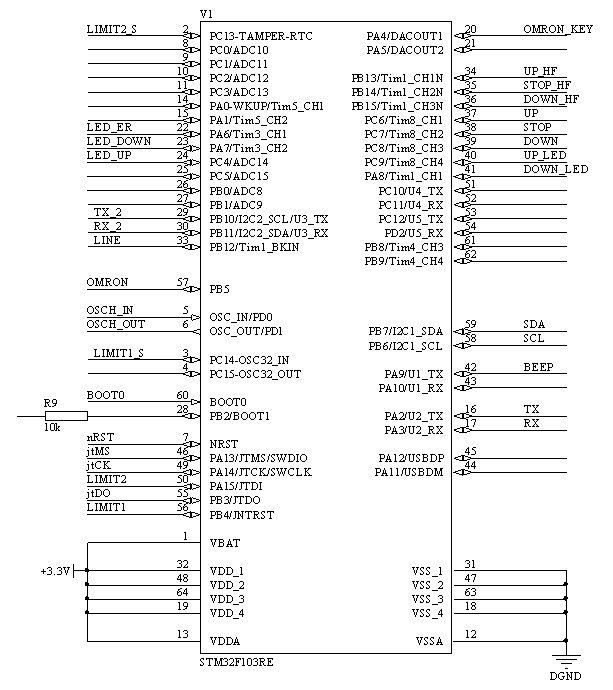

[0022] as attached Figure 1-7 Shown is the motor control device of the present invention, including a power supply, a remote control receiving unit, a central processing unit, a key display unit, a power drive circuit, a signal detection circuit, a left column 1, a right column 2, and a door panel 3; the central processing The device is connected to the power drive circuit; the power drive circuit drives the motor to work; the signal detection circuit is connected to the power drive circuit, the first DC brushless motor 4 and the second DC brushless motor 5 respectively; the signal detection circuit Used to obtain the signals of the power drive circuit, the first brushless DC motor 4 and the second brushless DC motor 5, and transmit them to the central processing unit. A DC brushless motor 4 and a second DC brushless motor 5; the first DC brushless motor 4 is arranged on the left colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com