Stone remover for mining dump vehicle

A mining dump truck and stone ejector technology, which is applied in vehicle maintenance, vehicle cleaning, deflectors, etc., can solve the problems of large tire extrusion wear and poor stone ejector effect, so as to reduce tire wear and avoid Complicated procedures, reduced daily maintenance costs and operational risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

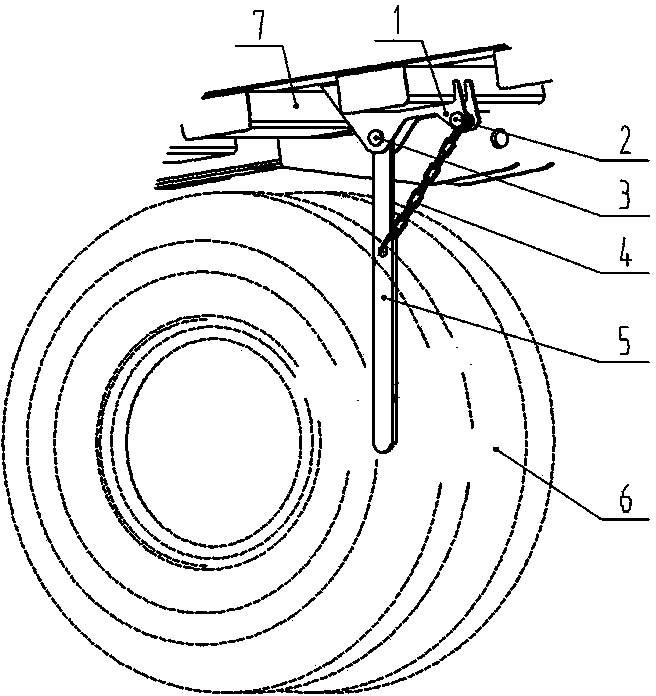

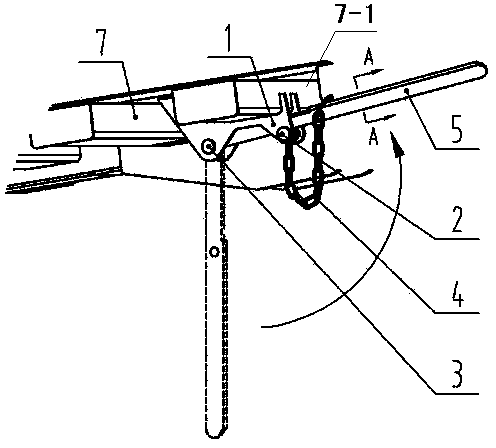

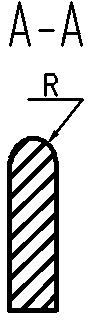

[0015] like figure 1 and figure 2 The shown mine dump truck stone ejector includes a rear wheel set consisting of two tires 6 arranged at intervals. The mine dump truck of this embodiment is equipped with two rear wheel sets through the rear axle, and is located at the two rear wheel sets. The bottom of the upper part is equipped with two fixed supports 1 for the car bucket 7, each fixed support 1 is connected to the car bucket 7 by welding, each fixed support 1 is hinged by the first pin shaft 3, and the end naturally hangs down to the The stone row bar 5 between the two tires 6 of the rear wheel group has a through hole in the middle part of the stone row bar 5. The stone row bar in this embodiment is a steel bar, and the side of the steel bar facing backward is a radius R. curved surfaces, such as image 3 Shown; On this through hole, be connected with a flexible limit rope 4, the flexible limit rope 4 of the present embodiment is an iron chain, and one end of the iron c...

Embodiment 2

[0018] like figure 2 In the mine dump truck stone ejector shown, a fixing device is installed on the car body 4 behind the fixed support 1. The fixing device in this embodiment is a hook (not shown in the figure), and the stone ejector rod 5 is wound around the first pin 3. Rotate backward to be roughly parallel to the bottom surface of the bucket 4 and fix it by a hook; other features are the same as in embodiment 1; in other embodiments, the fixing device is a clamp that can clamp the stone ejector rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com