Lamination device and corresponding lamination method

一种贴合装置、贴合的技术,应用在层压装置、化学仪器和方法、数据处理的输入/输出过程等方向,能够解决尚没有高效、通用的贴合装置等问题,达到高效性和通用性、方便曲面贴合的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

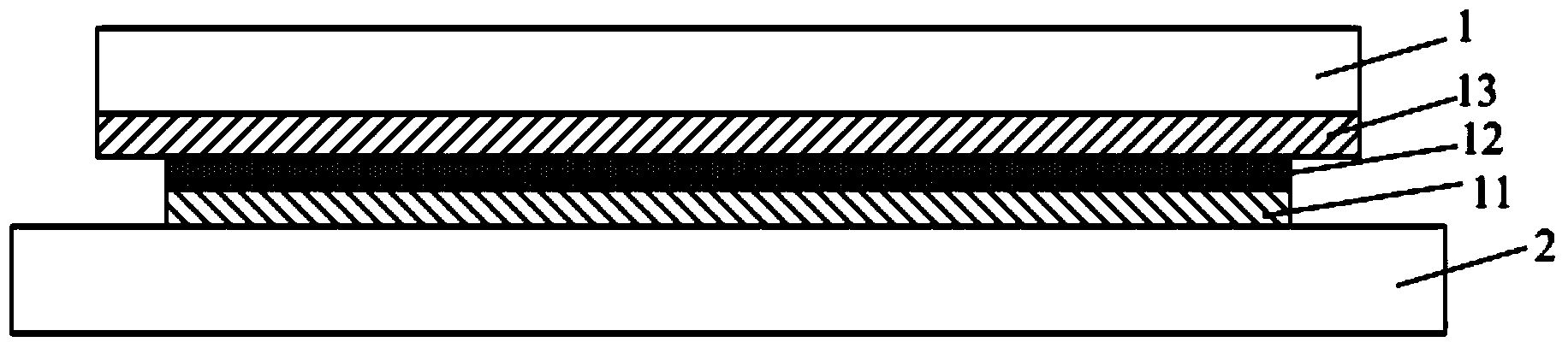

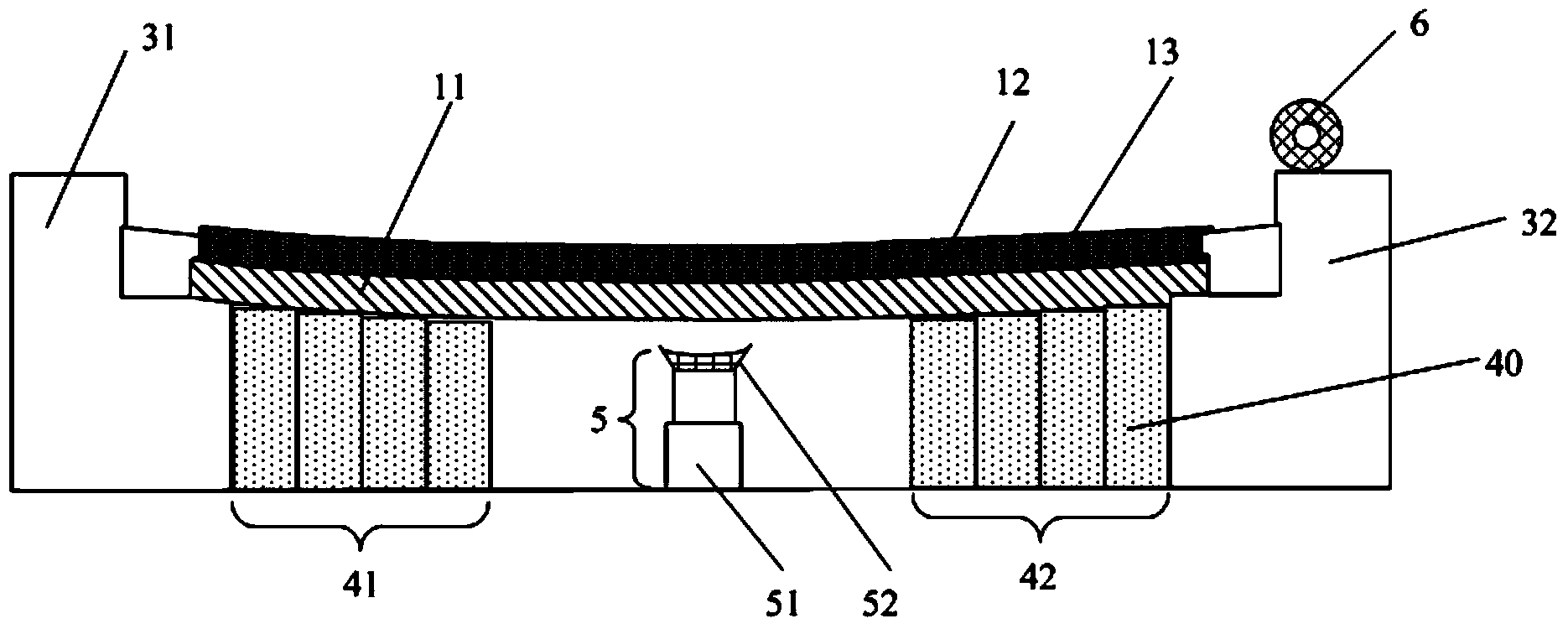

[0045] This embodiment provides a bonding device, which is used for bonding a display substrate and a touch substrate on a curved surface.

[0046] Such as figure 2 As shown, the bonding device includes a base 3, a curvature adjustment table 4 and a bonding roller 6, the base 3 is fixedly arranged, and the curvature adjustment table 4 includes a plurality of different heights, and can be relatively moved inside the base 3 The sub-table 40 is used to make the display substrate 11 (LCD Open Cell) and the touch substrate 13 (Touch Panel) to be bonded, which are arranged inside the base 3 and located above the curvature adjustment table 4, obtain a design. The bonding roller 6 is used to roll the display substrate 11 and the touch substrate 13 to be bonded to form a curved display panel.

[0047]The abutment 3 and the curvature adjustment workbench 4 are used as the workbench for the display substrate 11 and the touch control substrate 13 in the bonding process, which can suppor...

Embodiment 2

[0074] This embodiment provides a laminating device for laminating curved surfaces of a display substrate and a touch control substrate. Compared with Embodiment 1, the laminating device in this embodiment may not be provided with an adsorption unit.

[0075] Other structures of the bonding device in this embodiment are the same as the corresponding structures of the bonding device in Embodiment 1. Due to the reduction of the adsorption unit and the corresponding vacuum system, compared with Embodiment 1, the cost of the bonding device in this embodiment is lower Low; but at the same time, the flexibility requirements of the bonded display substrate and touch substrate are relatively high.

[0076] Correspondingly, this embodiment also provides a bonding method corresponding to the bonding device, which is used for bonding the display substrate and the touch substrate, including steps:

[0077] Step 1): forming an adhesive layer on the display substrate to be bonded;

[0078]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com