Wet desulfurization device for micro-pressure flue gas and seawater or reclaimed water desulfurization device

A wet desulfurization and flue gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of low flue gas pressure, complicated procedures, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

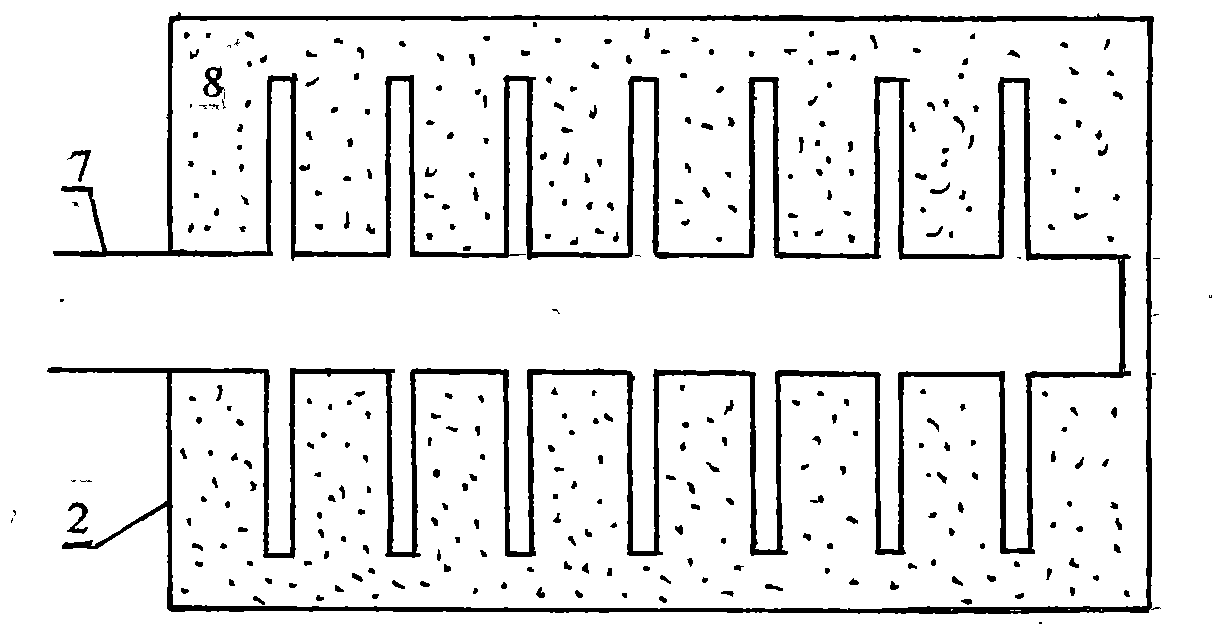

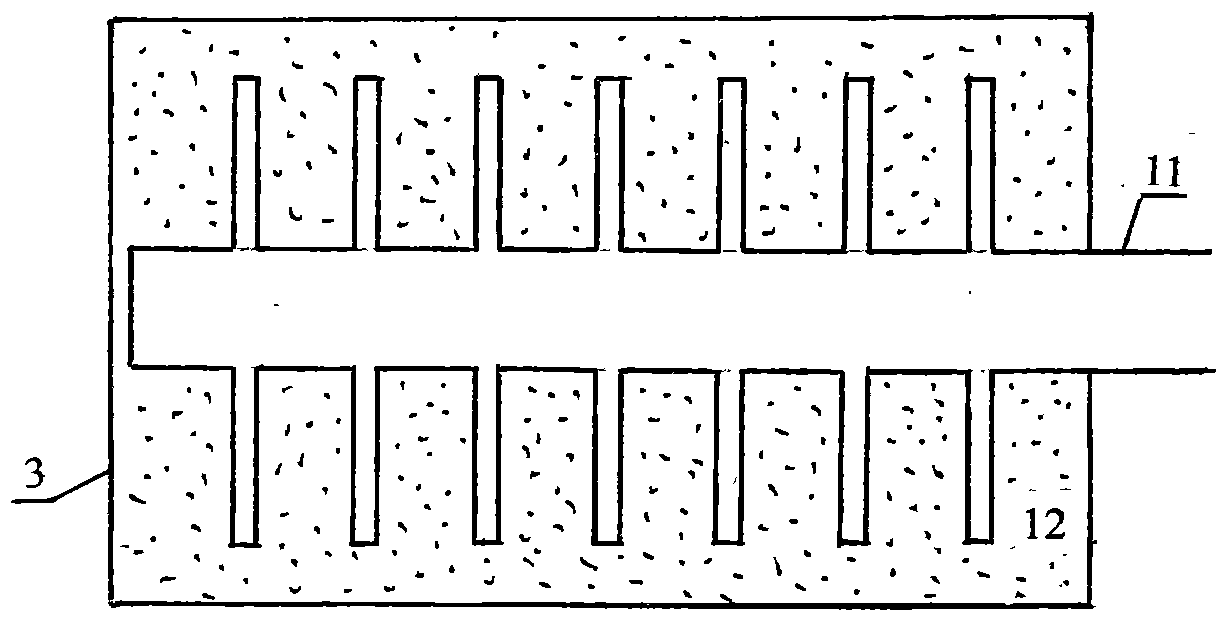

[0015] figure 1 , figure 2 , image 3 As shown, the wet desulfurization device for micro-pressure flue gas of the present invention is mainly composed of a desulfurization tank 2, an aeration tank 3, a sedimentation tank 4, a water collection tank 5, a blower 10, a chimney 14 and a water pump 6. There is a filter screen in the sump 5, and the water pump 6 pumps the filtered lime water in the sump 5 to the desulfurization pool 2. The sulfur dioxide and nitrogen monoxide in the flue gas are dissolved in the water of the desulfurization tank 2, and the sulfur dioxide and the lime react chemically in the desulfurization tank 2 to generate calcium sulfite. The desulfurized sewage passes through the water retaining plate and reaches the aeration tank 3, and a large amount of lime is placed in the aeration tank 3. The calcium sulfite in the aeration tank 3 chemically reacts with the oxygen in the wind blown by the blower 10 to generate calcium sulfate, and the nitrogen monoxide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com