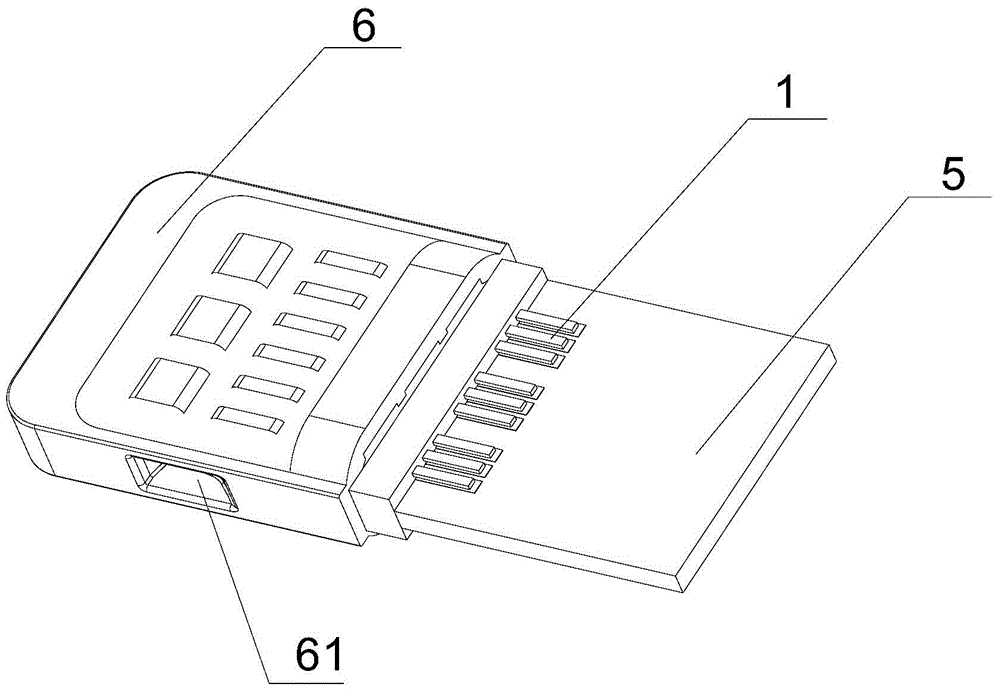

Double-sided plug connector and manufacturing method thereof

A plug-in connector and double-sided technology, which is applied in the field of double-sided plug-in connectors and its production, can solve the problems of not meeting the terminal height tolerance, poor terminal contact, appearance and burr, etc., to solve the problem of terminal height Tolerance is difficult to control, reducing poor contact of terminals or appearance of lagging and burrs, and reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details.

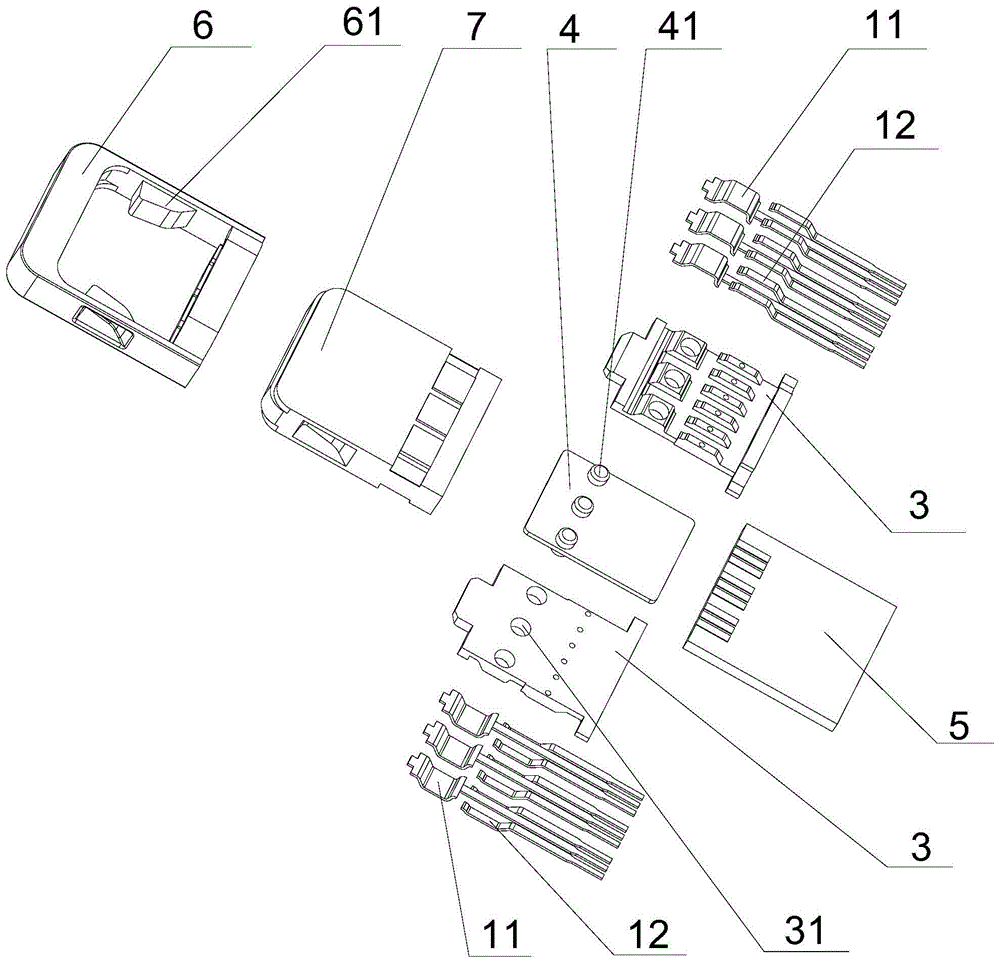

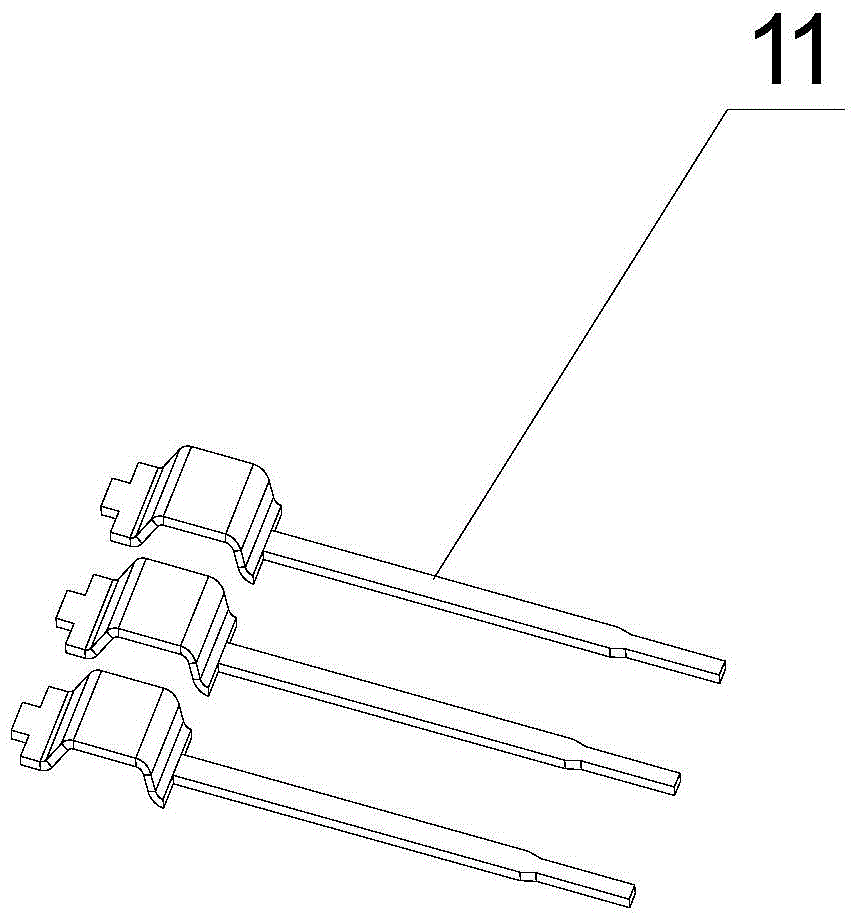

[0037] For the above-mentioned double-sided connectors that cannot meet the extremely strict terminal height tolerance requirements, resulting in poor terminal contact or product appearance and burrs, poor product quality, etc., the present invention adopts the process flow of injection molding-assembly-secondary injection molding, The problem of difficult control of the terminal height tolerance is solved by setting the elastic sheet, and the product cost is reduced while ensuring a high first-time success rate and product quality.

[0038] In the following descriptions of the specific embodiments of the present invention, "terminals" all refer to wiring terminals widely used in electrical or communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com