Driving mechanism of dual-power automatic transfer switch

An automatic transfer switch and driving mechanism technology, applied in the field of electromechanical manufacturing, can solve the problem of not preventing the main switch shaft from reversing, and achieve the effect of improving reliability and stability and increasing the self-locking of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

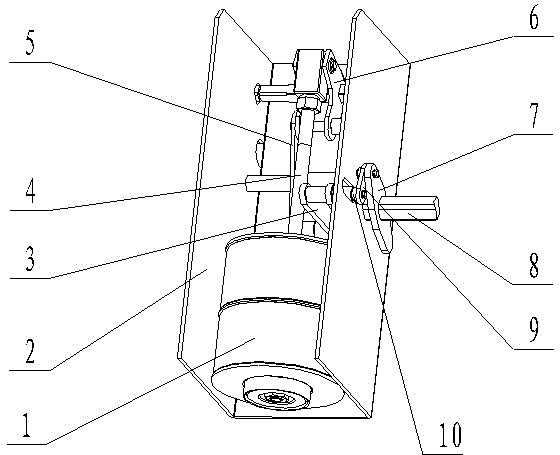

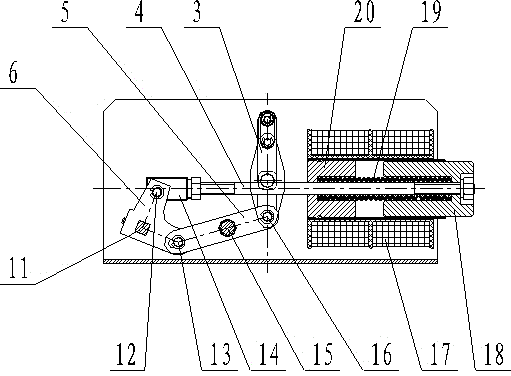

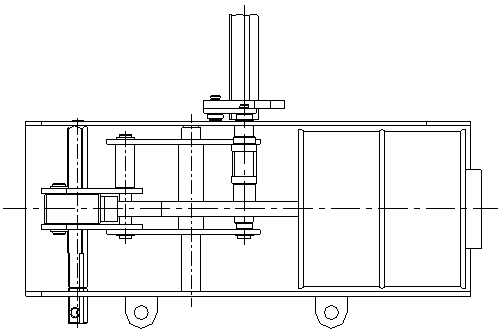

[0015] like figure 1 , figure 2 , image 3 As shown, the driving mechanism of the present invention mainly includes: driving electromagnet assembly 1, mounting bracket 2, connecting plate 3, push rod 4, lever 5, swinging plate 6, crank 7, main body switch shaft 8, connecting rod 9, Bearing pin 10,11 rotating shaft, hinge one 12, hinge two 13, connecting block 14, axle 15, hinge three 16, hinge four 21. The driving electromagnet assembly 1 includes: an excitation coil 17, a moving iron core 18, a spring 19, and a static iron core 20; the right end of the push rod 4 is fixed on the moving iron core 18, and the left end is fixed on the connecting block 14; the middle part of the swing plate 6 Fixed on the rotating shaft 11, it can rotate with the rotating shaft 11, and is connected with the connecting block 14 through the hinge shaft 12. The hinge shaft 12 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com