Method for calculating accurate feeding data of whole-mounting adjuster of large-diameter pressure steel pipe

A pressure steel pipe and calculation method technology, which is applied in calculation, electrical digital data processing, special data processing applications, etc., can solve problems such as difficult control of blanking size, and achieve the effect of solving difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 (compensation for pipe wall misalignment)

[0039] The calculation method of the accurate blanking data of "Section 68 of the pressure steel pipe of the 15# unit pressure steel pipe on the right bank of the Three Gorges" is as follows:

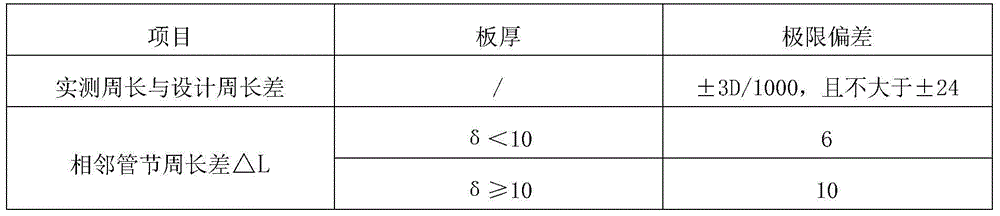

[0040] 1) Calculate the maximum pipe wall misalignment compensation amount △C brought about by the circumference difference between the joint 1 and the adjacent two penstocks 2 and 3: determine the maximum permissible circumference difference in penstock installation specifications according to the design drawings △ After L, according to the formula

[0041] △C=(△L / 2) / (2π)=(10mm / 2)÷(2×3.1415)=0.8mm

[0042] The calculation results in the maximum compensation amount of misaligned teeth on the pipe wall brought about by the difference in circumference of adjacent nozzles △C=0.8mm.

[0043] Among them, the value of △L is taken from the power industry standard "Code for Manufacture, Installation and Acceptance of Pressure Ste...

Embodiment 2

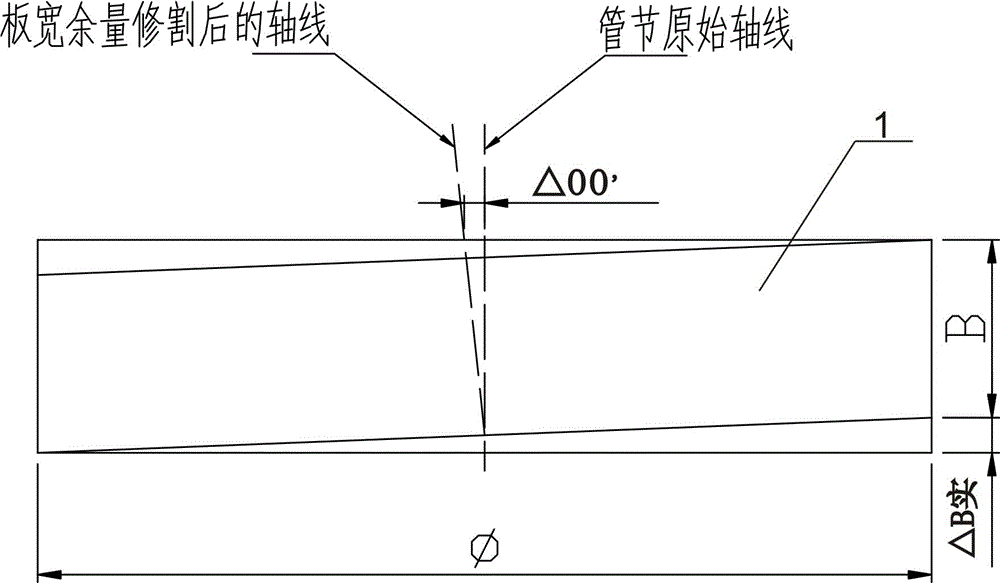

[0063] Embodiment 2 (Slab Width Margin Compensation)

[0064] The calculation method of the accurate blanking data of "the 73rd section of the pressure steel pipe of the 18# unit pressure steel pipe on the right bank of the Three Gorges" is as follows:

[0065] 1) Calculate the maximum pipe wall misalignment compensation amount △C brought about by the circumference difference between the joint 1 and the adjacent two penstocks 2 and 3: determine the maximum permissible circumference difference in penstock installation specifications according to the design drawings △ After L, according to the formula

[0066] △C=(△L / 2) / (2π)=(10mm / 2)÷(2×3.1415)=0.8mm

[0067] The calculation results in the maximum compensation amount of misaligned teeth on the pipe wall brought about by the difference in circumference of adjacent nozzles △C=0.8mm.

[0068] Among them, the value of △L is taken from the power industry standard "Code for Manufacture, Installation and Acceptance of Pressure Steel Pi...

Embodiment 3

[0089] Embodiment 3 (joint compensation)

[0090] The calculation method of the accurate blanking data of the 15# unit penstock section 73 of the pressure steel pipe on the right bank of the Three Gorges.

[0091] 1) Calculate the maximum pipe wall misalignment compensation amount △C brought about by the circumference difference between the joint 1 and the adjacent two penstocks 2 and 3: determine the maximum permissible circumference difference in penstock installation specifications according to the design drawings △ After L, according to the formula

[0092] △C=(△L / 2) / (2π)=(10mm / 2)÷(2×3.1415)=0.8mm

[0093] The calculation results in the maximum compensation amount of misaligned teeth on the pipe wall brought about by the difference in circumference of adjacent nozzles △C=0.8mm.

[0094] Among them, the value of △L is taken from the power industry standard "Code for Manufacture, Installation and Acceptance of Pressure Steel Pipes" DL5017, Section 4 Table 4.1.12

[0095] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com