Integrated engine online test bench

An online testing and engine technology, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., can solve problems such as low reliability, increased installation engineering, and high failure rate of secondary connections, so as to improve reliability High performance, easy operation, and the effect of avoiding secondary connection failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

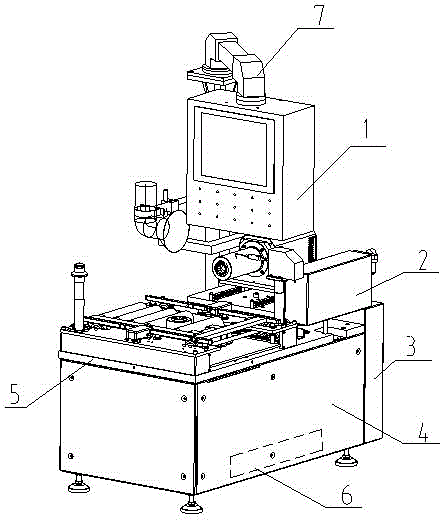

[0009] Such as figure 1 As shown, an integrated engine online test bench includes an integrated chassis 4, a load box 6, an electrical box 3, a workbench 5, an air control component box 2 and an operation control box 1; the workbench 5 It is arranged on the chassis 4, and is isolated from the chassis 4 by a rubber spring composite shock absorber; the air control component box 2 and the operation control box 1 are also arranged on the chassis 4, and are both rigidly connected to the chassis 4; The electrical box 3 is fixedly installed on the side of the chassis 4, and the load box 6 is fixed inside the chassis 4; the air control component box 2, the operation control box 1, the electrical box 3 and the load box 6 are not in direct contact with the worktable 5 In order to avoid the vibration of the workbench from being transmitted to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com