Device and method for measuring reflection of fiber ring fusion splicing point in photonic bandgap fiber optic gyroscope

A technology of photonic bandgap and fiber optic gyroscope, applied in the direction of measuring devices, instruments, etc., can solve the problems of testing, limited spatial resolution, inability to use melting point reflection, etc., and achieve the effect of simple measurement method and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

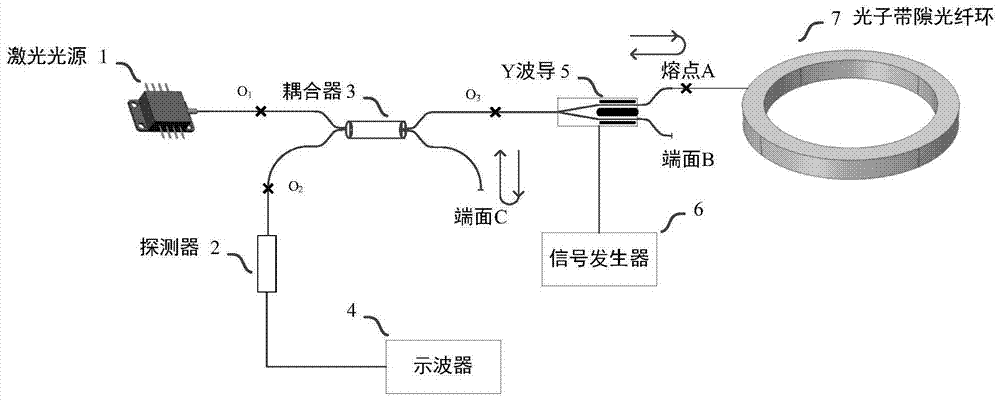

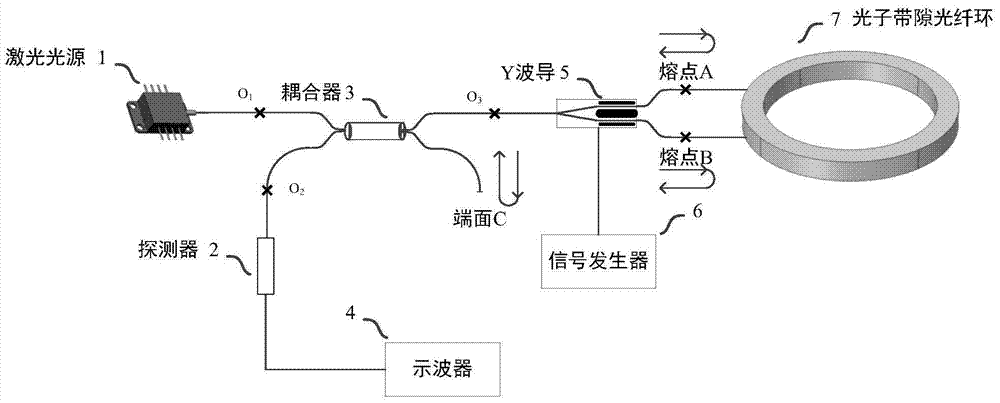

[0031] The invention is a measurement device for the reflection of the fusion point of the optical fiber ring in the photonic bandgap optical fiber gyroscope, such as figure 1 As shown, it includes a laser light source 1, a coupler 3, a Y waveguide 5, a photonic bandgap fiber ring 7, a detector 2, a signal generator 6, and an oscilloscope 4;

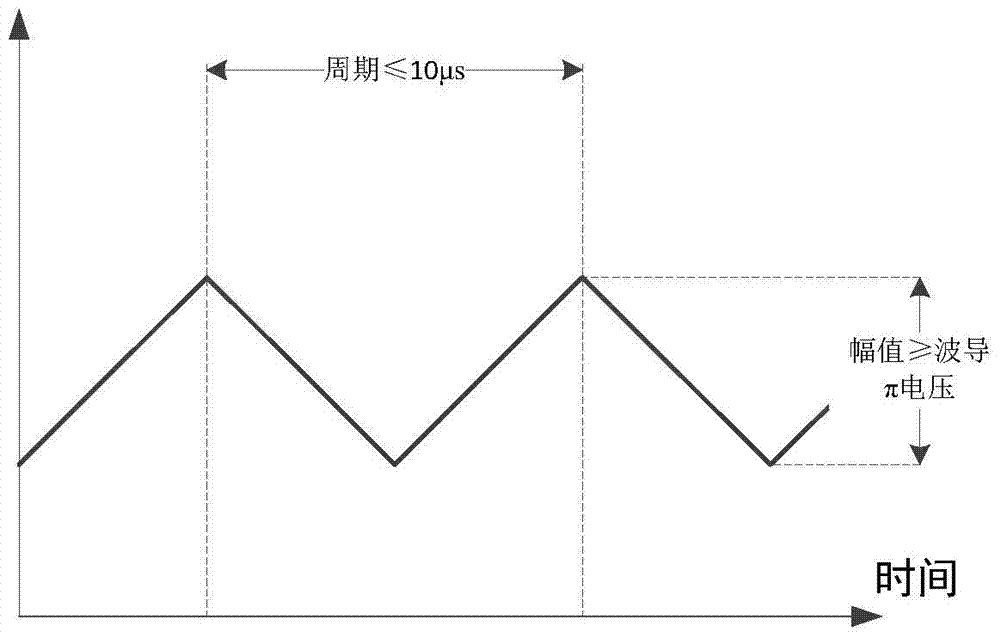

[0032] The output pigtail of laser source 1 and the O of coupler 3 1 The pigtails are connected by a flange, and the O of the coupler 3 2 end with detector 2 pigtail spliced, coupler O 3 The end is welded with the input pigtail of Y waveguide 5, and the output pigtail of Y waveguide 5 is provided with end face A and end face B. According to the measurement needs, choose end face A or end face B to be welded with the pigtail of photonic bandgap fiber ring 7, and the melting points are A or B respectively. B. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com