Joint with spirally-reinforcing rubber pipe

A rubber tube and spiral technology, applied in the field of rubber pipe joints with spiral reinforcement, can solve the problems of expansion and contraction rubber damage, affecting service life, etc., to improve bearing capacity, increase service life, and high air tightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

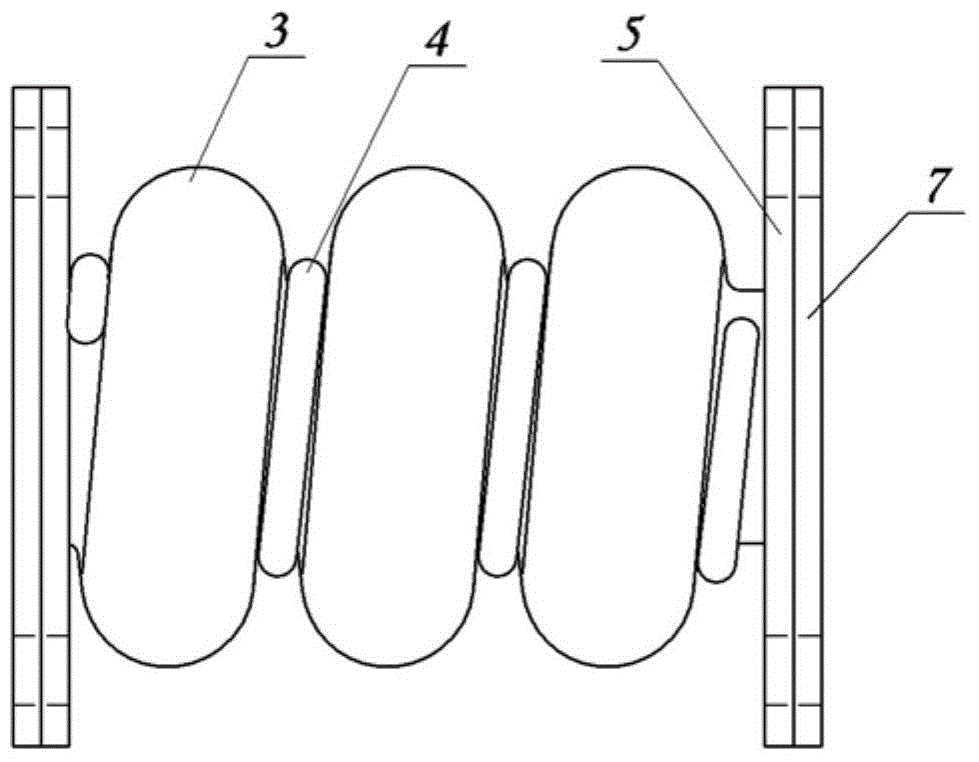

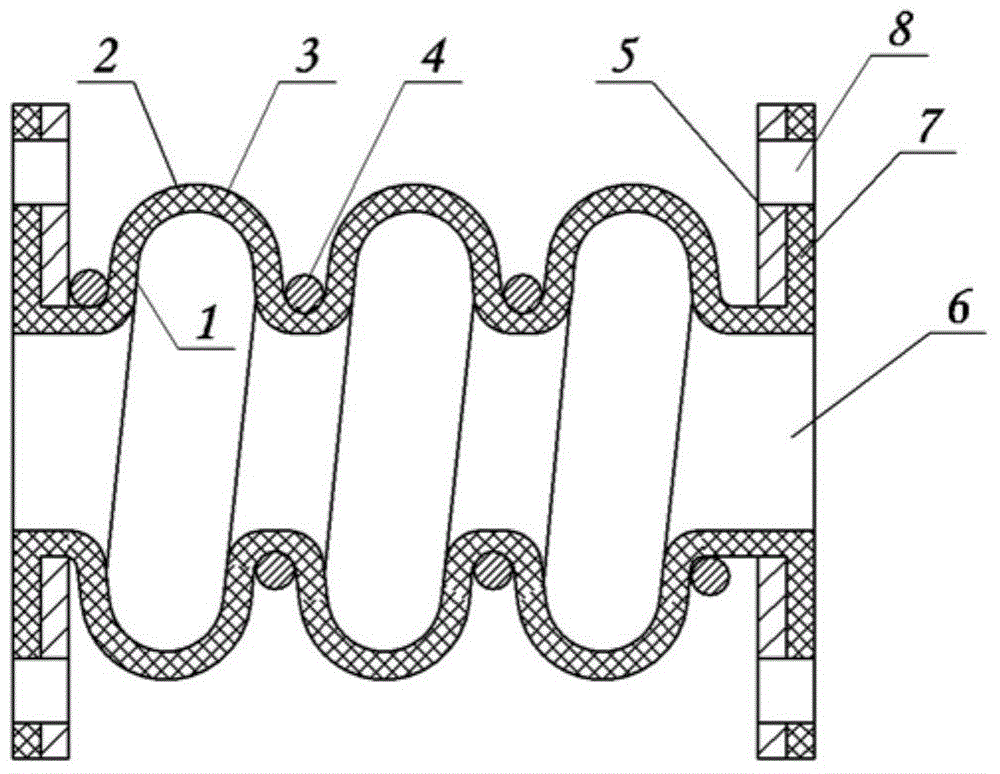

[0012] Embodiment 1: see figure 1 and figure 2 , a rubber pipe joint with helical stiffening. There are three spiral grooves in the middle of the rubber pipe, and a helical spring is matched in each groove.

[0013] The rubber tube includes a skeleton layer 3 in the center and rubber layers on both sides, namely an inner rubber layer 1 and an outer rubber layer 2 .

[0014] In addition, the two ends of the rubber tube are respectively straight pipe sections 6, and the mouth of the straight pipe section 6 is provided with a flange-shaped flange 7 outward, and the edge of the flange-shaped flange 7 is provided with a fixing hole. The inner sides of the flanges 7 are fitted with an annular flange 5 , which is matched with the flange-shaped flanges 7 , and the fixing holes 8 of the flange-shaped flanges 7 correspond to the fixing holes of the ring flanges.

Embodiment 2

[0015] Embodiment 2: The drawings are not drawn, and the content is basically the same as that of Embodiment 1. The difference is that in this embodiment, a double-helical groove is provided on the outside of the rubber tube and a double-helical spring is matched with it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com