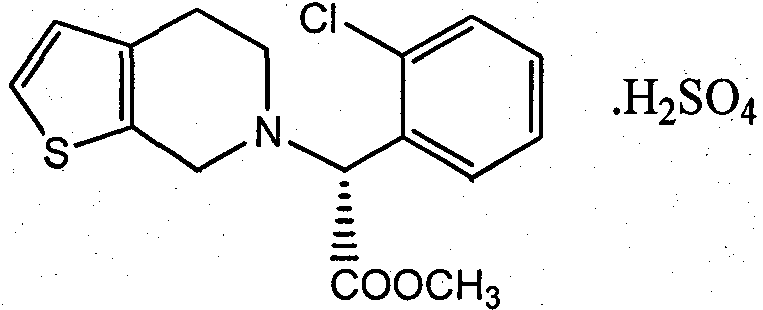

A kind of preparation method of clopidogrel bisulfate

A technology of clopidogrel hydrogen sulfate and concentrated sulfuric acid, applied in the field of preparation of clopidogrel hydrogen sulfate, can solve the problems of limited heating and reflux temperature, long route and the like, and achieve the effects of cost reduction, easy availability of raw materials and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

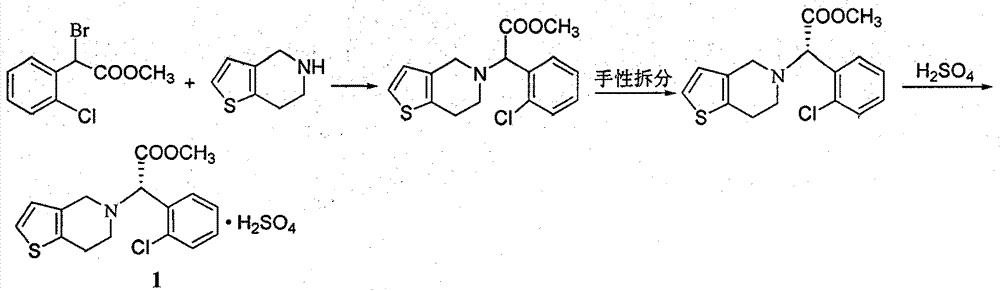

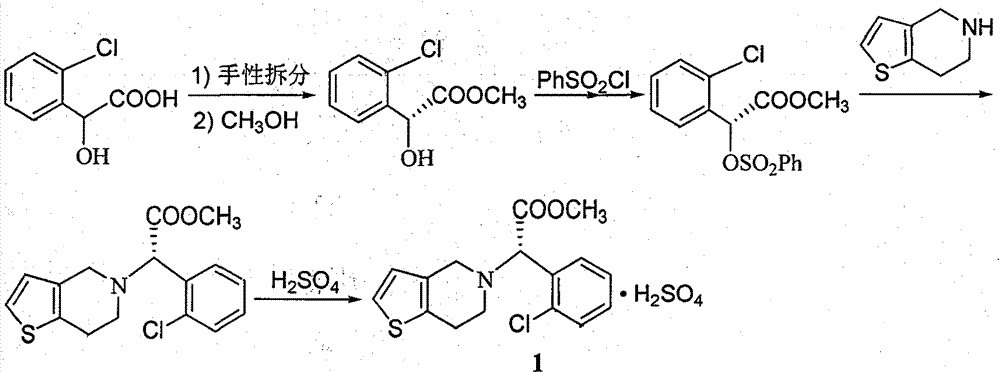

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of clopidogrel bisulfate of the present invention comprises the following steps:

[0036] 1) Weigh 12.6g of 2-thiopheneacetaldehyde and 20.0g of S-o-chlorophenylglycine methyl ester, add them into a 250mL three-necked reaction flask, then add 100mL of organic solvent toluene and 0.4g of catalyst ammonium acetate, heat and stir under reflux for reaction, the reaction The temperature was 110°C. TLC tracking and monitoring showed that the raw materials disappeared. The reaction solution was cooled to 25° C., 100 mL of water was added, stirred, and left to stand for separation. The toluene layer was dried with anhydrous sodium sulfate. Then it was filtered, and the filtrate was evaporated to dryness under reduced pressure to obtain a solid imine intermediate crude product, which was recrystallized with ethanol to obtain 28.7 g of pure imine intermediate, with a yield of 93.2%.

[0037] 2) Take 15.4 g of the imine intermediate obtained in step 1...

Embodiment 2

[0041] A kind of preparation method of clopidogrel bisulfate of the present invention comprises the following steps:

[0042] 1) Weigh 12.6g of 2-thiopheneacetaldehyde and 20.0g of S-o-chlorophenylglycine methyl ester, add them into a 250mL three-necked reaction flask, then add 100mL of solvent chloroform and 0.6g of catalyst ammonium chloride, heat and stir to reflux, the reaction temperature The temperature was 60°C, TLC tracking monitoring showed that the raw materials disappeared, the reaction solution was cooled to 20°C, 100mL of water was added, stirred and left to separate layers, and the chloroform layer was dried with anhydrous sodium sulfate. Then it was filtered, and the filtrate was evaporated to dryness under reduced pressure to obtain a solid imine intermediate crude product, which was recrystallized with ethanol to obtain 27.9 g of pure imine intermediate, with a yield of 90.6%.

[0043] 2) Take 15.4 g of the imine intermediate obtained in step 1) and add it to ...

Embodiment 3

[0047] A kind of preparation method of clopidogrel bisulfate of the present invention comprises the following steps:

[0048] 1) Weigh 12.6g of 2-thiopheneacetaldehyde and 20.0g of S-o-chlorophenylglycine methyl ester, add them into a 250mL three-necked reaction flask, then add 100mL of solvent methylene chloride and 0.4g of catalyst ammonium acetate, heat and stir under reflux, and react The temperature was 40°C, and TLC tracking monitoring showed that the raw materials disappeared. The reaction solution was cooled to 30°C, 100mL of water was added, stirred and allowed to stand for separation, and the dichloromethane layer was dried with anhydrous sodium sulfate. Then it was filtered, and the filtrate was evaporated to dryness under reduced pressure to obtain a solid imine intermediate crude product, which was recrystallized with ethanol to obtain 28.8 g of pure imine intermediate, with a yield of 93.5%.

[0049] 2) Weigh 15.4g of the imine intermediate obtained in step 1) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com