Lifting high-speed roller bed conveying mechanism

A technology of conveying mechanism and lifting drive motor, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

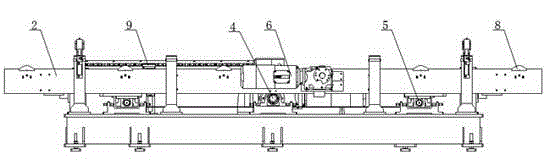

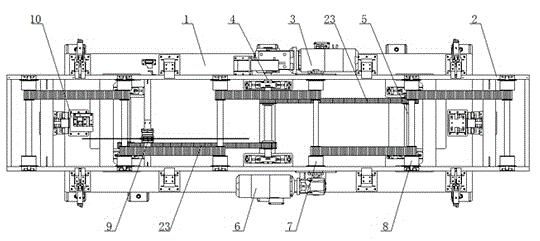

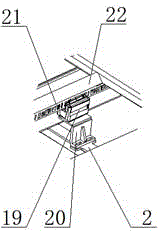

[0019] like figure 1 , figure 2 As shown, a lifting high-speed roller bed conveying mechanism includes a base 1, a lifting drive unit on the base 1, a lifting platform 2, a roller conveying device on the lifting platform 2, a guiding positioning device, and a trolley full-range identification and positioning device; figure 2 As shown, a lifting drive unit is installed on the base 1, and the lifting drive unit includes a lifting drive motor 3, a transmission main shaft 4, two synchronous belts 23 and two lifting crankshafts 5, and the lifting drive motor 3 Linked to the transmission main shaft 4, the transmission main shaft 4 constitutes a synchronous transmission device through two synchronous belts 23 and two lifting crankshafts 5, the torque of the lifting driving motor 3 can be evenly and synchronously transmitted to the two lifting crankshafts 5, The lifting platform 2 is lifted and lowered smoothly and synchronously.

[0020] like figure 2 As shown, a roller convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com