A bolt tightening device

A bolt and floating device technology, applied in the field of automobile assembly equipment, can solve problems such as bolt tightening failure, and achieve the effect of improving the first-time success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

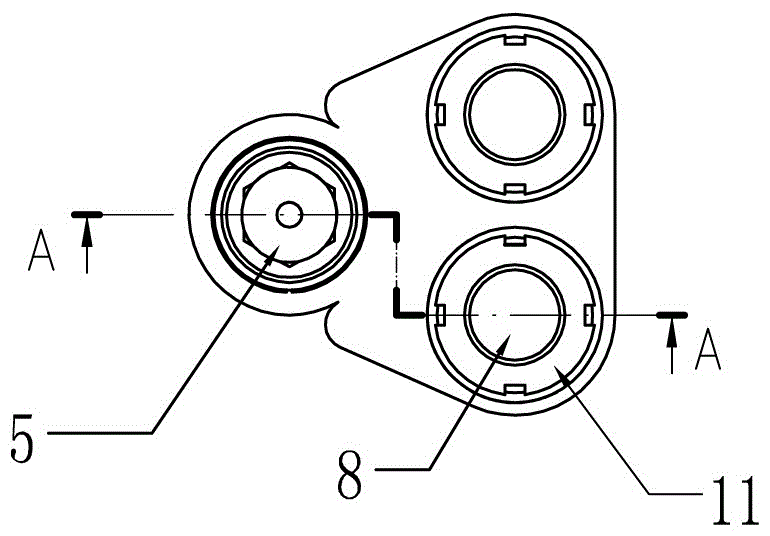

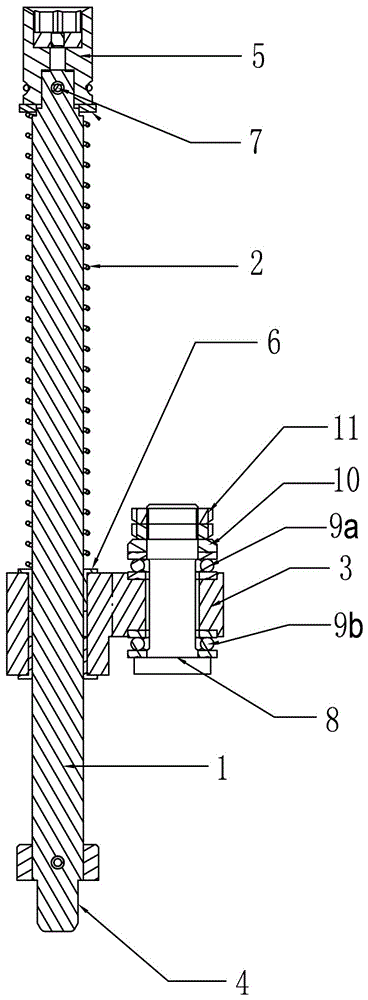

[0014] Such as Figure 1-2 As shown, a bolt tightening device described in the embodiment of the present invention mainly includes a set of transmission rods, two sets of identical floating devices and a mounting base 3, the cross section of the mounting base 3 is triangular, and the transmission rods are installed on the mounting base 3 On one of the top corners, two sets of floating devices are respectively installed on the other two top corners of the mounting base 3. The transmission rod system mainly includes the transmission rod 1, the compression spring 2 and the socket wrench 5, and the socket wrench 5 is fixed on the transmission rod 1 The top end and the bottom end of the transmission rod 1 are provided with a hexagonal column head 4, the transmission rod 1 is inserted on the mounting seat 3 and can slide up and down along the mounting seat 3, and the compression spring 2 is sleeved on the transmission rod 1, and the two ends are against the socket wrench 5 and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com