Universal adjustable pipe female welding bracket

A welding bracket, adjustable technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of increasing construction period, increasing welding time, troubles of construction units, etc., to achieve welding speed and quality improvement, ensure The effect of rotational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

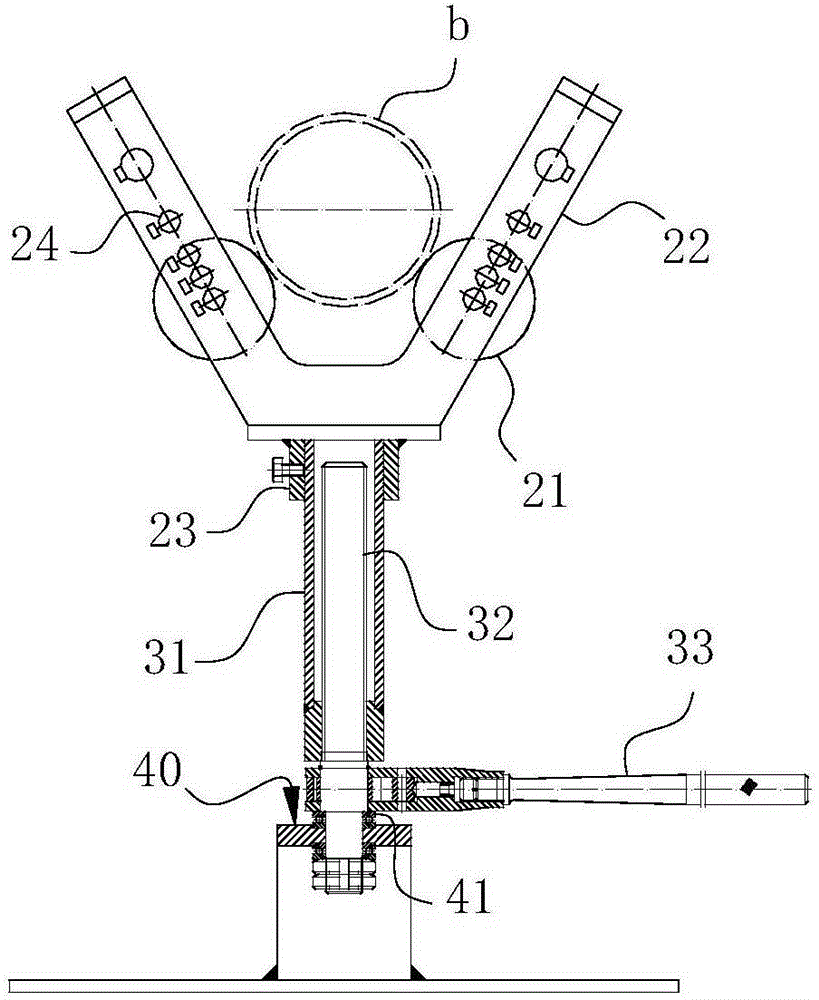

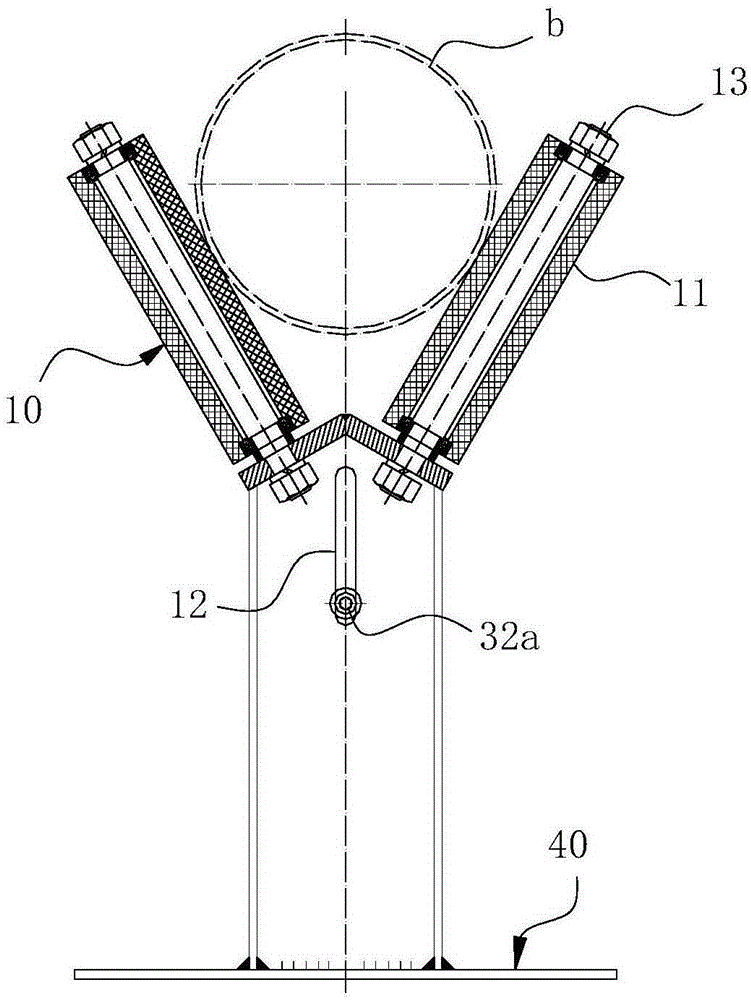

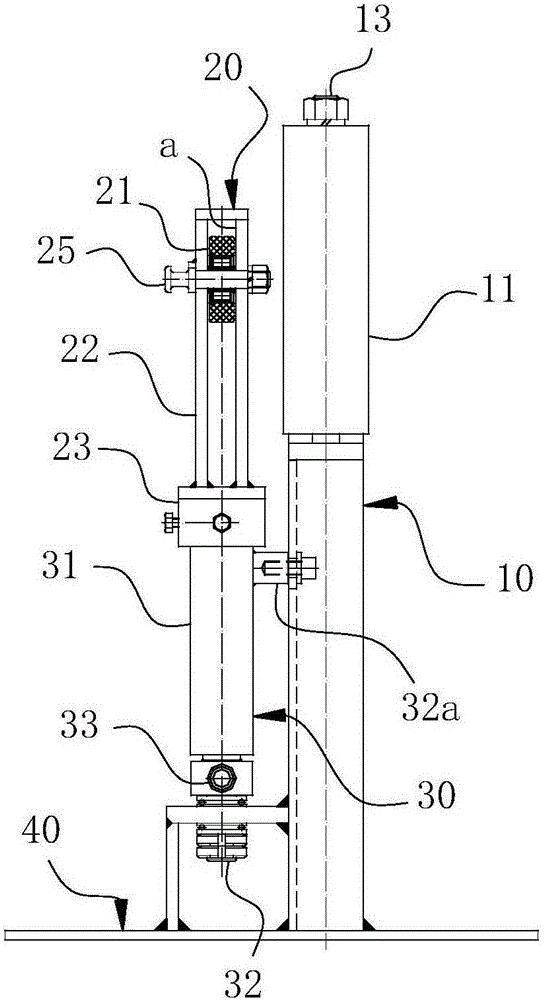

Image

Examples

Embodiment example

[0042] Implementation case:

[0043] Using the traditional pipe mother support frame welding process:

[0044] Anhui Fuyang (Fuer) 500 kV substation adopts the welding method of the traditional support frame, and we have made statistics on the welding time of some of its pipe mother welding joints, as shown in Table 1 below:

[0045] Table 1: Fuyang (Fuer) 500 kV substation pipe mother welding time statistics

[0046]

[0047] Through the above statistics, it is not difficult to find that the welding installation process of the traditional welding support frame takes about 2.5 hours for each welding head, and the welding of the entire 500kV area requires at least 15 days, which is an extremely long cycle.

[0048] The welding process using the universal adjustable pipe female welding bracket of the present invention:

[0049] Anhui Huainan Kongdian 500 kV substation is one of the key projects invested and constructed by Anhui Electric Power Company in 2014. The 500 kV mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com