Superposition type voice coil motor and process for manufacturing same

A voice coil motor and production process technology, applied in the field of a superimposed voice coil motor and its production process, can solve the problems of long waiting time for glue to be fixed, lower yield rate, low production efficiency, etc., so as to shorten the glue curing time, The effect of reducing the use of glue and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

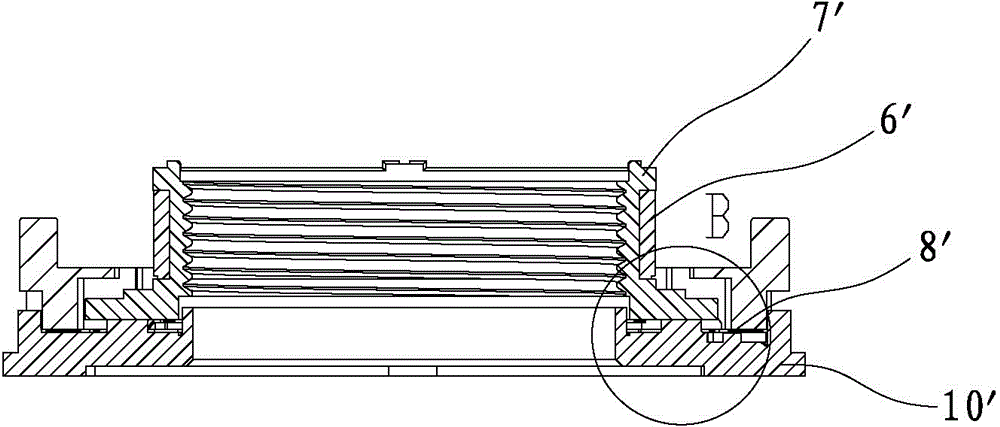

[0027] Such as image 3 As shown, the present invention is a superposed voice coil motor, which includes a yoke plate 1, an upper cover 2, an upper shrapnel 3, four magnets 4, a lower gasket 5, a coil 6, a bracket 7, a lower shrapnel 8, two Terminal 9 and lower cover 10.

[0028] The four pieces of magnets 4 are respectively pasted and fixed on the bottom surfaces of the four corners of the upper elastic piece 3, and the upper elastic piece 3 is fixedly sleeved in the upper cover 2, and the upper cover 2 together with the upper elastic piece 3 is sleeved in the yoke plate 1. Open gap 11 respectively on the two corners of plate 1 (as image 3 shown).

[0029] The coil 6 is wound on the bracket 7, the bottom surface of the bracket 7 is bonded and fixed to the top surface of the inner edge 81 of the lower elastic piece 8, the bracket 7, the lower elastic piece 8 and the lower cover 10 are stacked together, and the boss 71 on the bottom surface of the bracket 7 Insert the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com