Divided conductor clamp fitting for EHV (Extra-High Voltage) DC (Direct Current) convertor station and branch clamps thereof

An ultra-high voltage DC, split wire technology, used in conductive connections, clamping/spring connections, electrical components, etc., can solve the problem of the seam being located outside the branch clamp, etc., to improve the anti-corona performance and ensure the anti-corona performance. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

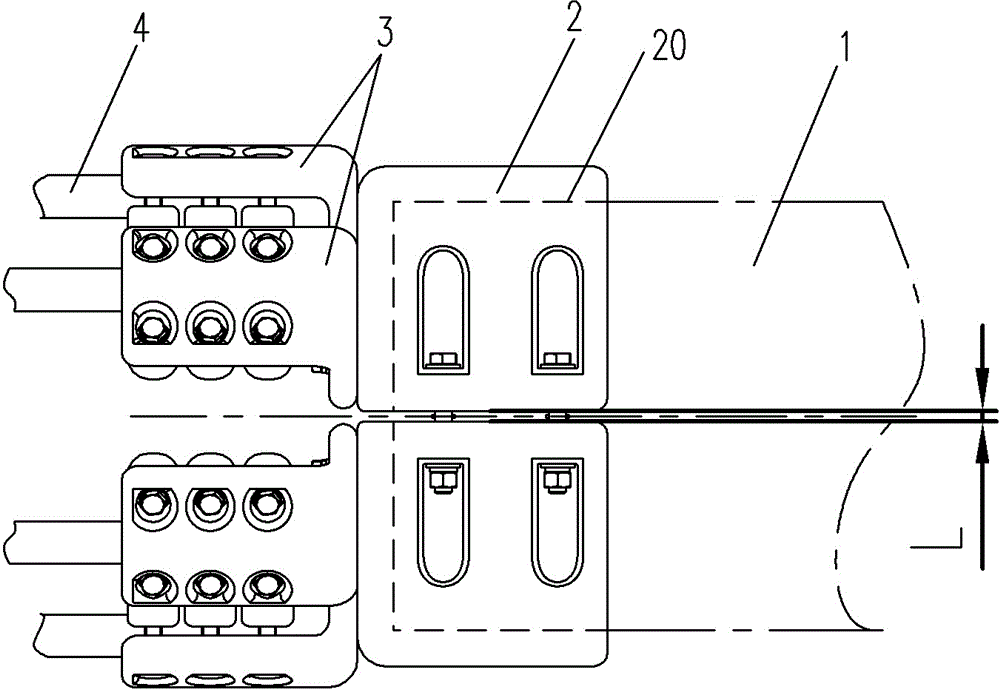

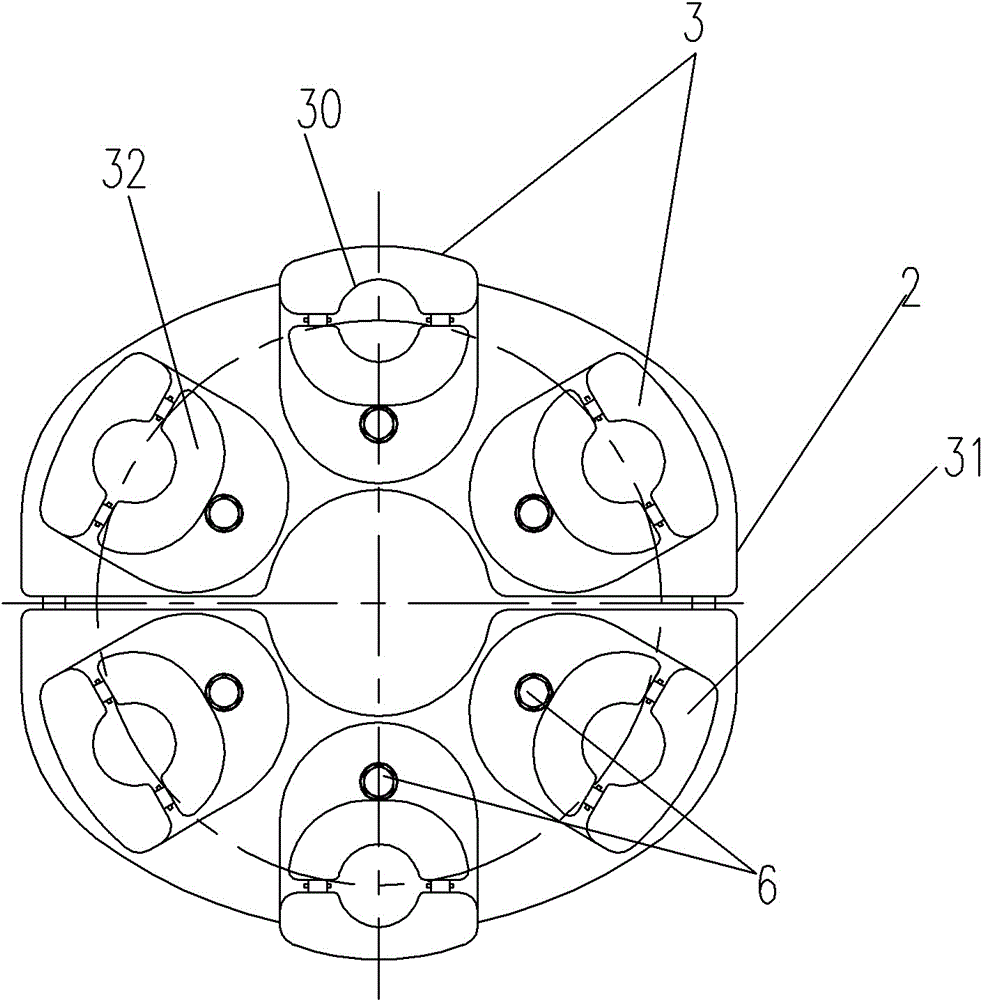

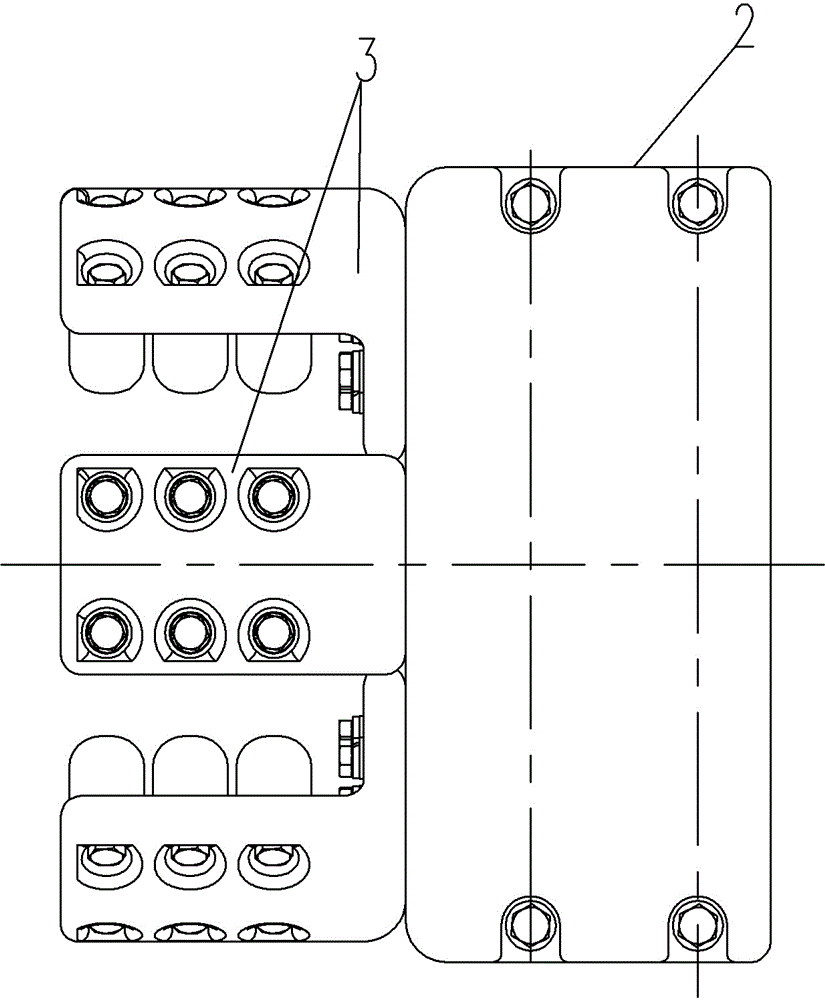

[0037] like Figure 1 to Figure 11As shown, an embodiment of a split wire clamp fitting for an UHV DC converter station, the line clamp fitting in this embodiment includes a busbar clamp 2, and the busbar clamp 2 is provided with a busbar hole 20 for clamping the busbar 1. One end of the busbar clamp 2 extending axially along the busbar hole 20 is fixed with six branch line clamps 3 uniformly distributed around the busbar hole circumferential direction, and each branch line clamp 3 has a coaxial and parallel arrangement with the busbar hole 20 for clamping branch lines 4 The branch line hole 30.

[0038] The bus bar clamp 2 in this embodiment includes two semicircular pipe mother holding clips 25 that are correspondingly assembled together. An installation step 24 is provided, and a bolt hole is correspondingly arranged on the installation step 24, and the connecting bolt 7 is correspondingly inserted into the bolt hole. The two pipe female holding clips 25 respectively have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com