Preheating switching device for fuse breaking capacity test

A technology of breaking capacity and switching devices, which is applied in the direction of measuring devices, instruments, fuse testing, etc., can solve the problems of not being able to meet the requirements of automatic monitoring and not reflecting arc characteristics, so as to reduce the risk of burning out, improve the test success rate, and changeover time The effect of small intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

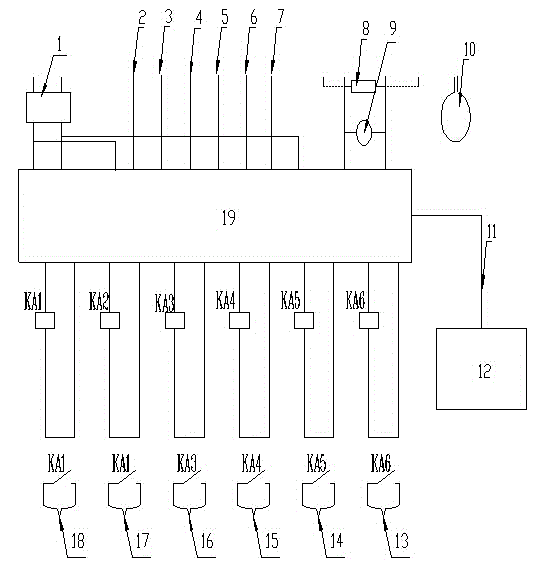

[0016] Such as figure 1 Shown is a preheating conversion device for fuse breaking capacity test, which includes switching power supply 1, programmable controller 19, monitoring / operation computer 12, Rogowski coil + integrator 10, programmable controller 19 and monitoring / The operating computer 12 is connected through the communication cable 11, and the programmable controller 19 is respectively connected with the low-voltage side current step-up limit 2, the low-voltage side current step-down limit 3, the closing indication of the isolation circuit breaker 4, and the opening indication of the isolation circuit breaker 5. High voltage circuit breaker closing indication 6. High voltage circuit breaker opening indication 7. Shunt 8. High voltage circuit breaker opening operation 13. High voltage circuit breaker closing operation 14. Is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com