Mechanical sealing leakage detection system and method

A leak detection and mechanical seal technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of the fluid, etc., can solve the problem of online quantitative detection of leakage, difficult mechanical seal, and incapable of real-time and accurate detection of machinery. Seal leakage and other issues to achieve the effect of fast detection speed and high accuracy of results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

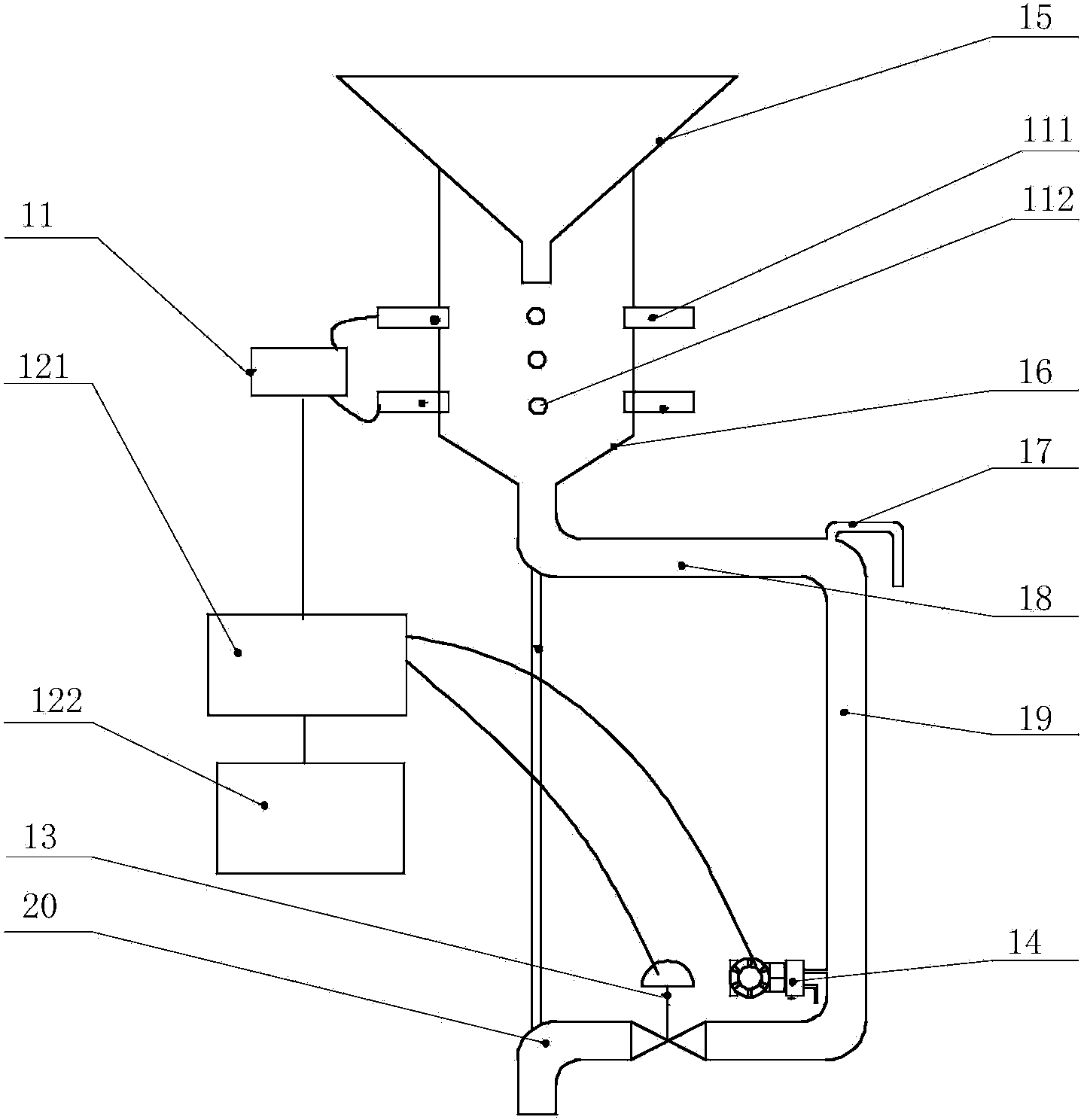

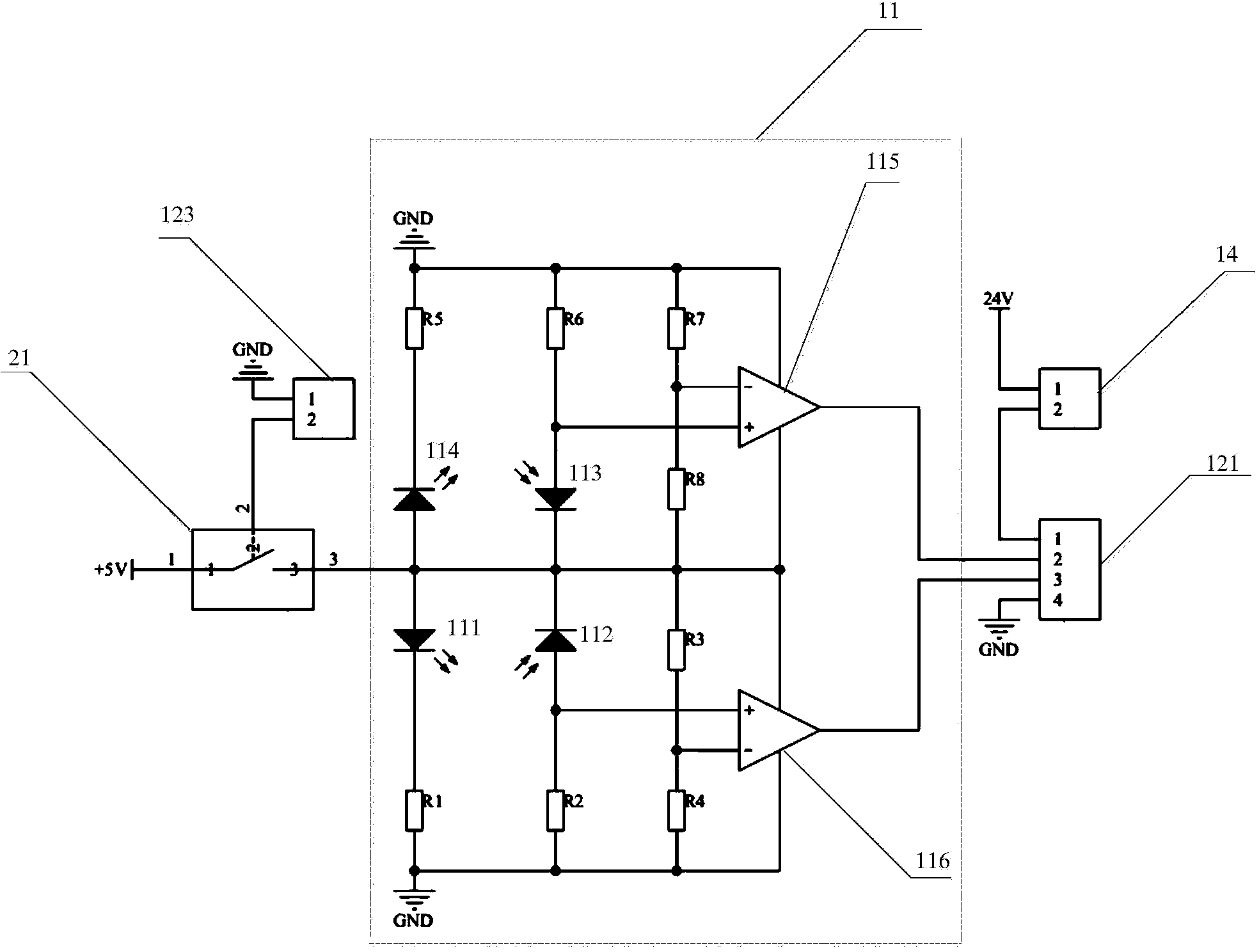

[0033] This embodiment provides a mechanical seal leakage detection system, which is applied to long-distance pipeline oil pumps, such as figure 1 As shown, the system includes: a droplet detection unit 11, a data processing unit 12; wherein,

[0034] The droplet detection unit 11 is configured to collect a first flow signal of the leaked liquid amount according to an optical detection method when it is detected that the leaked liquid amount meets the droplet counting condition;

[0035] The data processing unit 12 is configured to acquire the first flow signal collected by the liquid drop detection unit 11, and determine the first flow of the leakage liquid according to the first flow signal.

[0036] Here, the system further includes: a solenoid valve 13, and after determining the second flow rate of the leakage liquid according to the first flow signal, the data processing unit 12 is used to: control the solenoid valve 13 to be in a closed state In order to avoid more oil ...

Embodiment 2

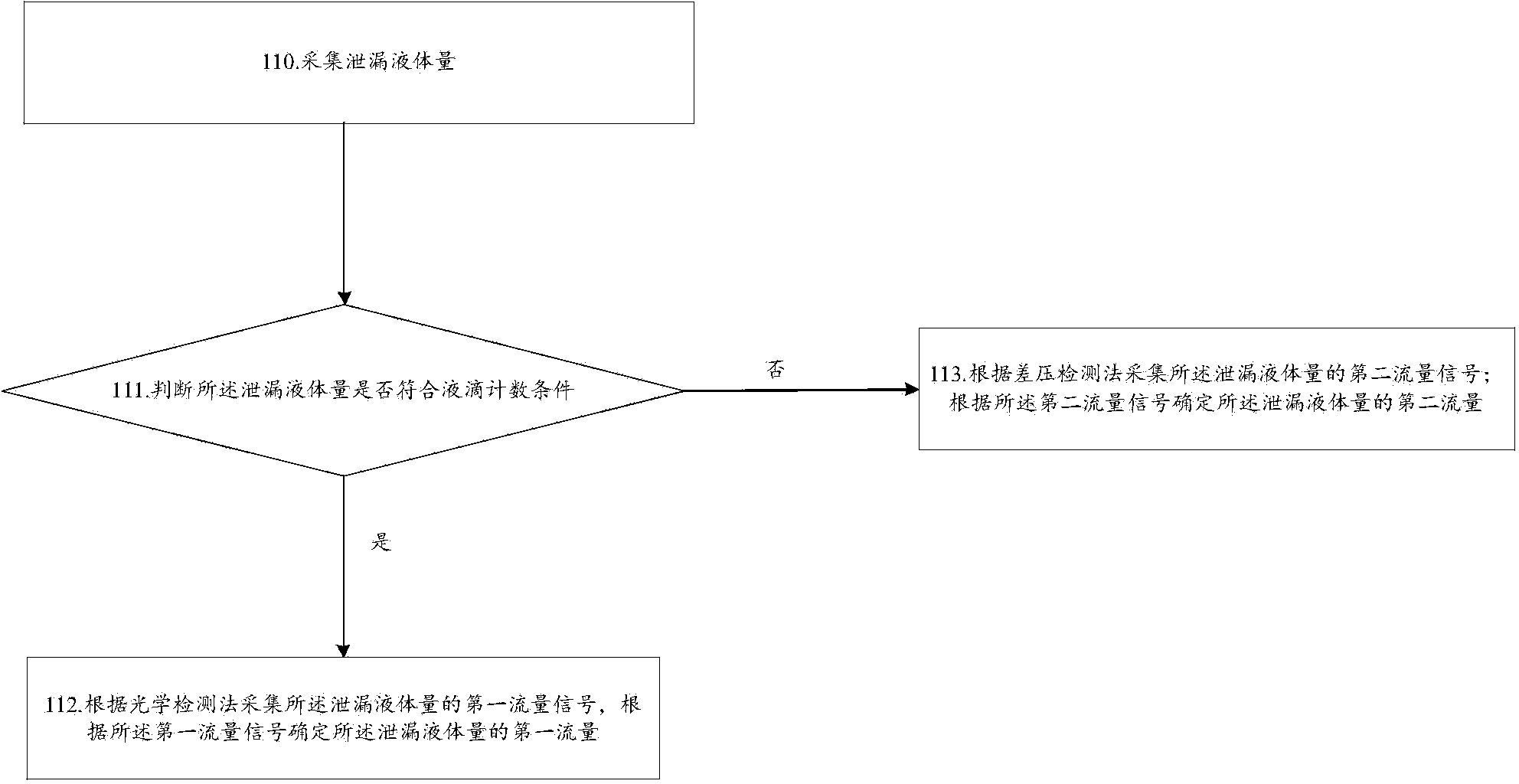

[0057] Compared with Embodiment 1, this embodiment also provides a mechanical seal leakage detection method, such as image 3 As shown, the method mainly includes the following steps:

[0058] Step 110, collecting the amount of leaked liquid;

[0059] In this step, when the amount of liquid leaked by the mechanical seal is small, that is, when the amount of leaked liquid exists in the form of droplets, the droplet detection unit collects the droplets through the droplet collection funnel; when the amount of liquid leaked by the mechanical seal is large , that is, when the amount of leaked liquid exists in the form of a liquid flow, the differential pressure detection unit collects the liquid flow through the liquid collection unit.

[0060] Step 111, judging whether the amount of leaked liquid meets the drop counting condition, if yes, execute step 112; if not, execute step 113;

[0061] In this step, it is judged by the droplet detection unit whether the amount of leaked li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com