Dynamic Calibration Device and Calibration Method of Built-in Hatch Door Force Measurement Box Balance

A box-type balance and dynamic calibration technology, which is applied to measuring devices, force/torque/power measuring instrument calibration/testing, instruments, etc., can solve the problems of balance dynamic response lag, dynamic error, and poor dynamic performance of box-type balances, etc. , to facilitate operation and loading, reduce interference effects, and reduce test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

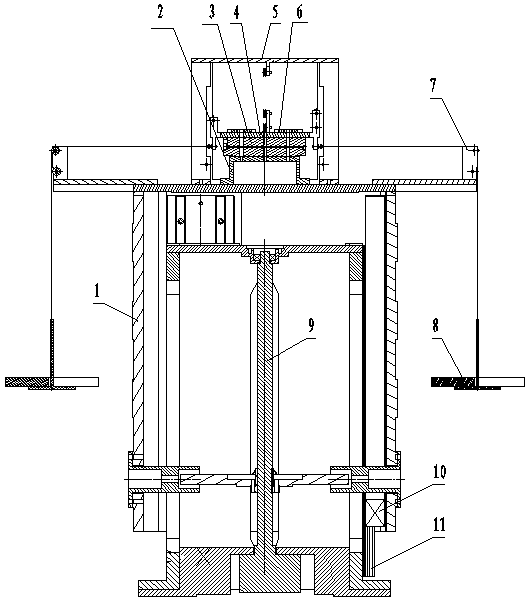

[0024] A dynamic calibration device for a box-type balance with a built-in hatch door force measurement test, which consists of: a calibration platform 1, a lifting unit is installed in the calibration platform, and a calibration base 2 is installed on the top of the calibration platform 1. A cassette balance 3 is housed on the described calibration base, and a loading mechanism is provided on the described cassette balance. The above positioning pin holes and the above mounting screw holes are fixed on the calibration platform.

Embodiment 2

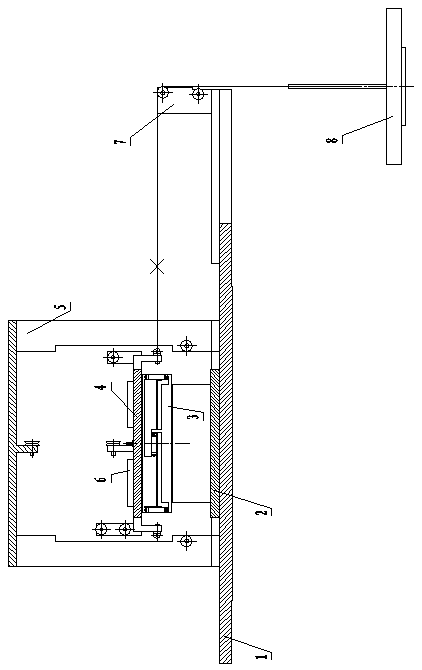

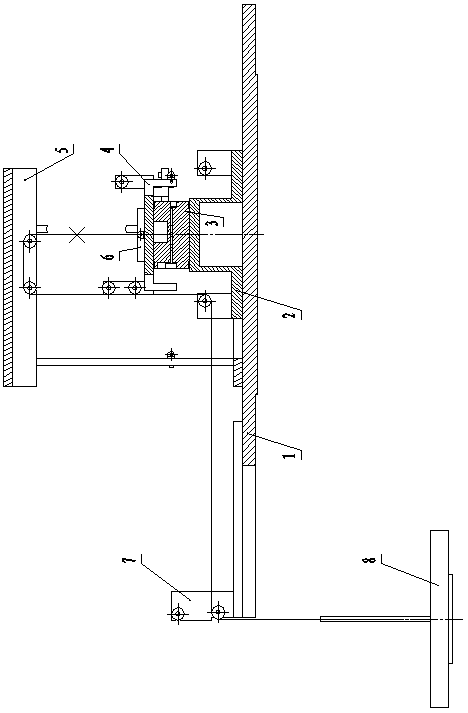

[0026] For the dynamic calibration device of the box-type balance of the embedded hatch door dynamometer test described in Embodiment 1, the described loading mechanism includes the loading head 4, the loading frame and the auxiliary pulley frame, and the loading head, the loading frame and the auxiliary pulley frame are mounted on The fixed pulleys are respectively arranged, and the v-grooves of the pulleys are used to wind the loading wire;

[0027] Connect the steel wires to the screws at the loading points of the three force elements of the loading head, mount the weight with the help of the auxiliary pulley frame, and realize the dynamic step calibration test of the three force elements by manually cutting the steel wires;

[0028] Steel wires are wound around the pulleys on the loading head. One end of the steel wires is fixed on the loading frame 5, and the other end is suspended with a weight 8 by means of an auxiliary pulley frame 7. The dynamic step calibration test o...

Embodiment 3

[0030] For the dynamic calibration device of the box-type balance of the built-in hatch door dynamometer test described in embodiment 1 or 2, the described lifting mechanism includes a spiral lifting mechanism 9, and a linear grating ruler 10 is installed at the bottom of the calibration platform; the described The linear grating scale is connected with the cross roller unit 11; a set of positioning pin holes and mounting screw holes are processed on the upper part of the calibration platform, and the calibration platform passes through the positioning pin holes, the mounting screw holes and the The auxiliary pulley frame and the loading frame are fixed on the calibration platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com