Force arm cross beam micro jacking device of ultra-large tool edge type torque standard machine

A technology of super large knife and jacking device, which is applied in the fields of torque testing device, torque detection and calibration, and measurement and testing, and can solve the problems of uncertain position and easy offset of the lever beam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0017] The ultra-large knife-edge type torque standard machine arm beam micro-lifting device of the present invention can realize the lifting amount of the arm beam by 0.03 mm to 0.08 mm.

[0018] The concrete implementation method of the present invention is as follows:

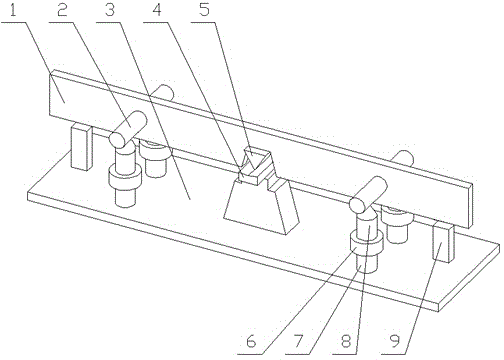

[0019] The schematic diagram of the overall structure of the device is shown in figure 1 As shown, a super-large knife-edge torque standard machine force arm beam micro-jacking device, including force arm beam 1, force arm beam support 2, base 3, knife holder 4, tool 5, force sensor 6, high precision Drive motor 7, jacking column 8, high-precision non-contact displacement sensor 9. The force arm crossbeam 1 can be lifted slightly by 0.03mm~0.08mm through the micro-displacement jacking of the four jacking columns jointly controlled by the pressure sensor and the laser displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com