Sludge conveying system

A conveying system and sludge technology, applied in transportation, packaging, storage devices, etc., can solve problems such as low construction efficiency, large damage to the surrounding environment, and poor carrying capacity of the backfill area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

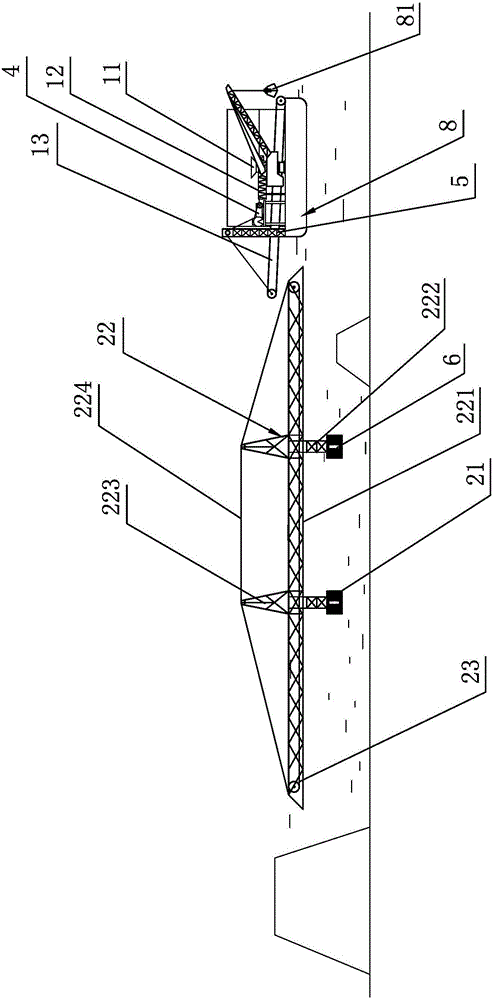

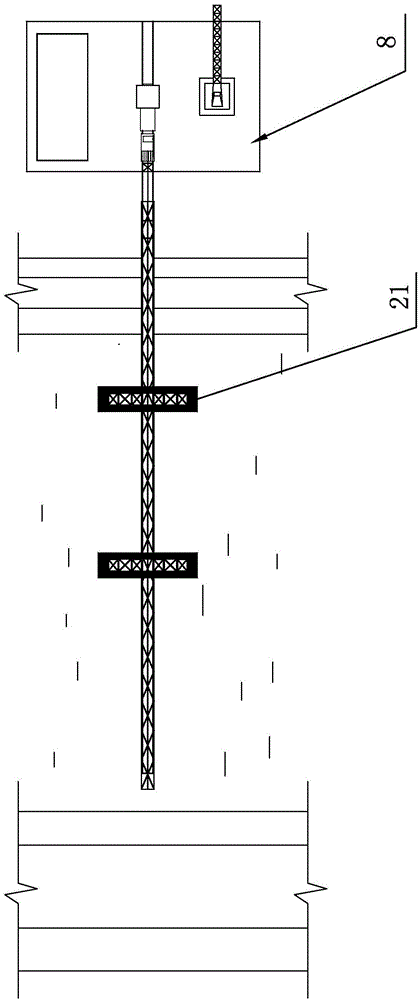

[0027] A kind of sludge conveying system that present embodiment proposes, such as Figure 1 to Figure 3 As shown, it includes a grab dredger 8 working on the water, an auxiliary conveying mechanism arranged on the grab dredger 8 and a main conveying mechanism working in the backfill area. The auxiliary conveying mechanism is conveyed by a hopper 11 and a screw. Conveyor 12 and auxiliary belt conveyor 13, screw conveyor 12 is installed on the grab dredger 8, the feed port of the hopper 11 receives the grab 81 of the grab dredger 8 from the inland beach For sludge, the discharge port of the hopper 11 is connected with the feed port of the screw conveyor 12, the discharge port of the screw conveyor 12 is located directly above the belt of the auxiliary belt conveyor 13, and the head end of the auxiliary belt conveyor 13 is fixed on the grab On the bucket dredger 8, the end of the auxiliary belt conveyor 13, that is, the discharge end, is suspended outside the grab dredger 8, and...

Embodiment 2

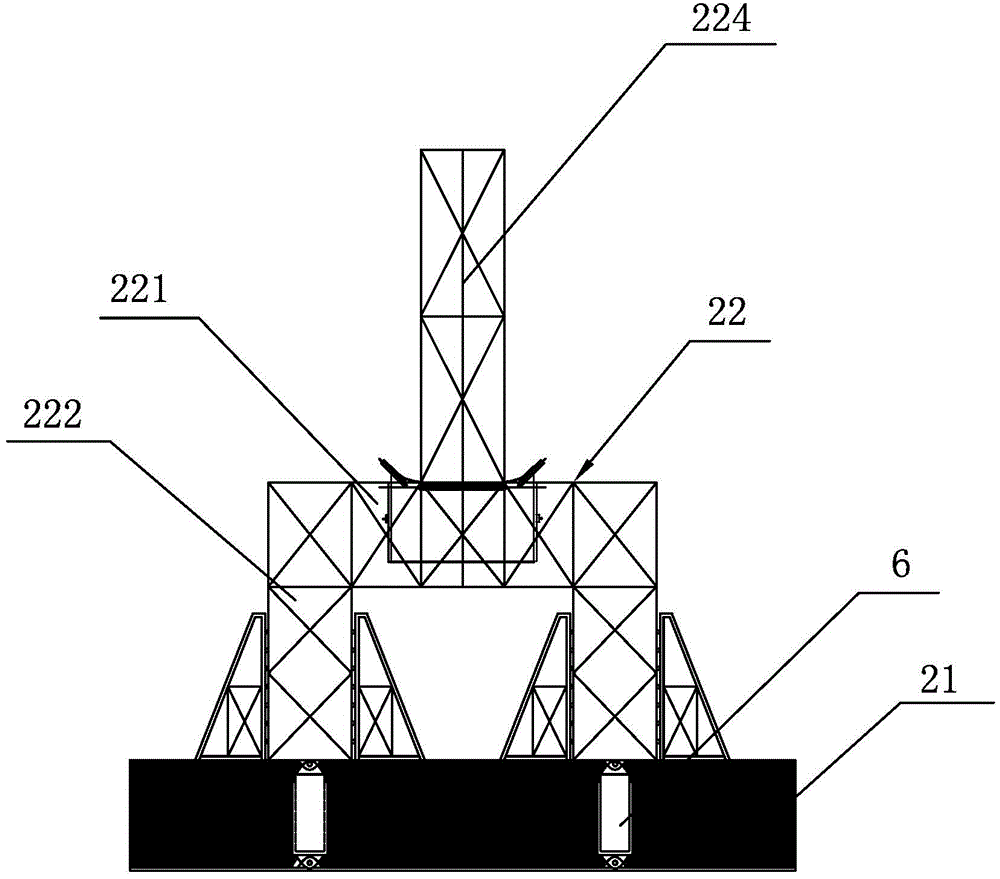

[0034] A kind of sludge conveying system that present embodiment proposes, such as Figure 4 As shown, it includes an excavator 9 working on land, an auxiliary conveying mechanism arranged on land, and a main conveying mechanism working in a backfill area. The auxiliary conveying mechanism is composed of a hopper 11 and a screw conveyor 12, and the screw conveyor 12 enters One end of the material is fixed on the land, one end of the discharge of the screw conveyor 12 is suspended, the feed port of the hopper 11 receives the mud grabbed by the grab bucket 91 of the excavator 9, and the discharge port of the hopper 11 is connected with the feed port of the screw conveyor 12. The feed port is connected, and the main conveying mechanism is composed of two flat-bottomed floating bodies 21, steel trusses 22 and main belt conveyor 23. The machine 23 is installed on the steel truss 22, the end of the main belt conveyor 23, that is, the discharge end is located directly above the backf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com