Wire device of simple woven cloth packaging machine

A packing machine and textile cloth technology, applied in packaging, paper/cardboard containers, containers, etc., can solve the problems of troublesome packing efficiency of textile cloth, untidy operation site, messy operation site, etc., and achieve a clean and orderly packing operation site. Clean packing site and easy packing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

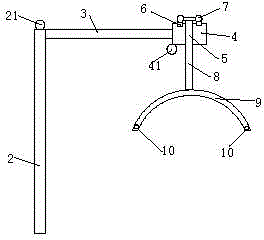

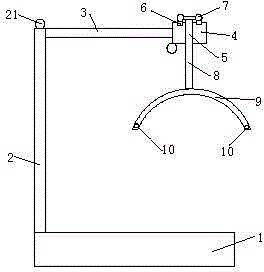

[0011] Combine below figure 1 and figure 2 Specific description embodiment:

[0012] Such as figure 1 and figure 2 As shown, a simple baler for textile cloth, the simple baler for textile cloth includes a base 1, one side of the base 1 is provided with several support rods 2, and the top of the support rod 2 is provided with a horizontal connection Rod 3, one end of the horizontal connecting rod 3 is vertically connected with the support rod 2, the other end of the horizontal connecting rod 3 is connected with a guide plate 4, and the guide plate 4 is provided with a guide plate that runs through the upper and lower sides of the guide plate 4. gap 5, the guide plate 4 is provided with guide rails 6 along both sides of the gap 5, the guide rails 6 are provided with two sets of pulleys 7, and the two sets of pulleys 7 are connected by suspension plates 8, so The suspension plate 8 passes through the gap 5 and is connected with a guide piece 9, the guide piece 9 is in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com