Passable railway wheel set inspection platform with rotary drive

A technology of a rotary drive device and maintenance platform, which is applied in the directions of transportation and packaging, vehicle maintenance/repair, vehicle maintenance, etc. It can solve the problems of low safety, high labor intensity, and high operation intensity, and achieve high safety and labor intensity. The effect of low and low work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The content of the present invention will be described below in conjunction with specific embodiments.

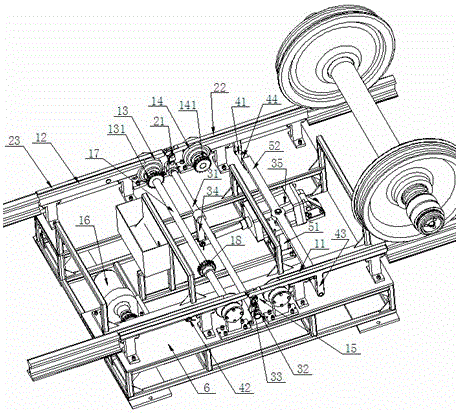

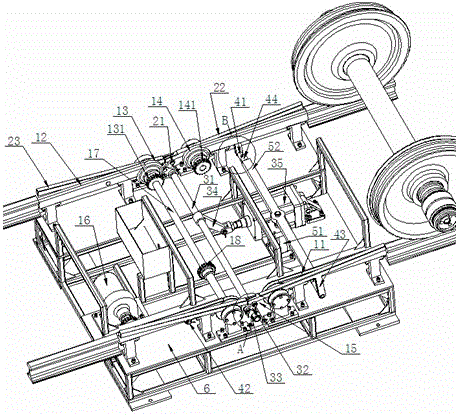

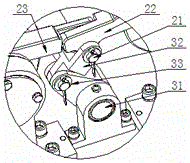

[0023] Such as Figure 1 to Figure 5 As shown, it is a structural schematic diagram of a passable railway wheel set maintenance platform with a rotary drive device according to the present invention. The passable railway wheel set maintenance platform with rotary drive device of the present invention includes: a base 6 and a reducer 16 arranged on the base 6, a wheel set entry track 11, a wheel set delivery track 12, and a friction drive wheel One 13, friction driving wheel two 14 and hinged connection protection rotating shaft 21.

[0024] The wheel rotation drive mechanism, the wheel rotation drive mechanism includes the collinear wheel pair entry track 11 and the wheel pair delivery track 12, between the wheel pair entry track 11 and the wheel pair delivery track 12 The first friction driving wheel 13 and the second friction driving wheel 14 are provided, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com