Automatic driver loading device of full-automatic LED bulb light base assembly machine

A technology of automatic loading and driving, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as low production efficiency and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

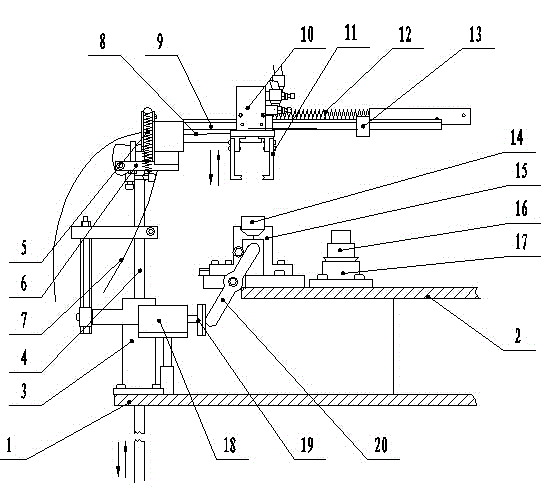

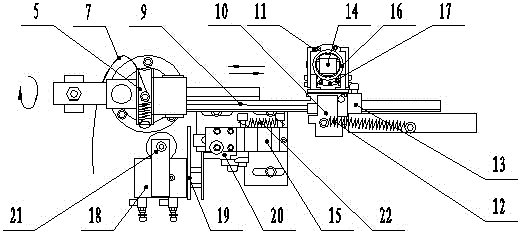

[0015] The invention includes a driver clamping and opening device and a driver transfer device;

[0016] The driver clamping and opening device: it is arranged on the index plate 2, including the driver fixture 15 for clamping the driver 14. The driver fixture 15 is composed of two parts, and the two parts are arranged so that the two parts are closely matched together to realize the alignment of the driver fixture. 15 clamped driver clamp extension spring 22 is also provided with a driver clamp opening device 19 that overcomes the pulling force of the driver clamp extension spring 22 to open the two parts;

[0017] Described driver transfer device: comprise packing into manipulator clamp 11, be provided with on the manipulator clamp 11 that makes it load into the vertical drive mechanism of manipulator clamp 11 move up and down; Rotary rotary drive.

[0018] The longitudinal driving device: includes a loading manipulator cable 8 connected to the manipulator gripper 11, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com