Fully automatic interweaving method for reinforcing bar nets of underground continuous wall

An underground continuous wall and steel mesh technology, applied in the field of construction machinery, can solve the problems of large volume of steel cages, unsafe, non-continuous foundation walls, etc., and achieve the effect of reducing the amount of labor and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

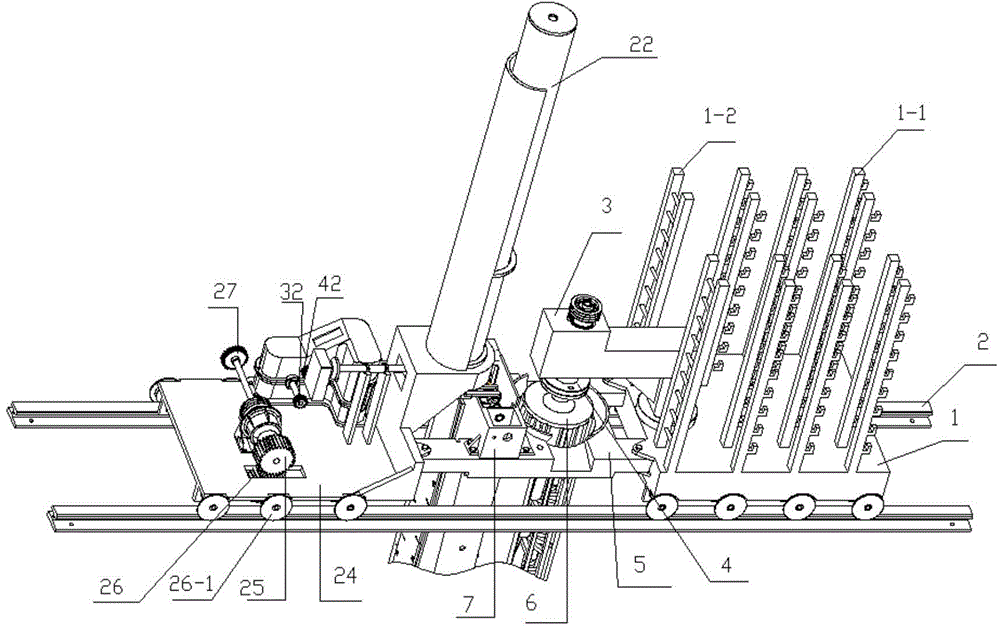

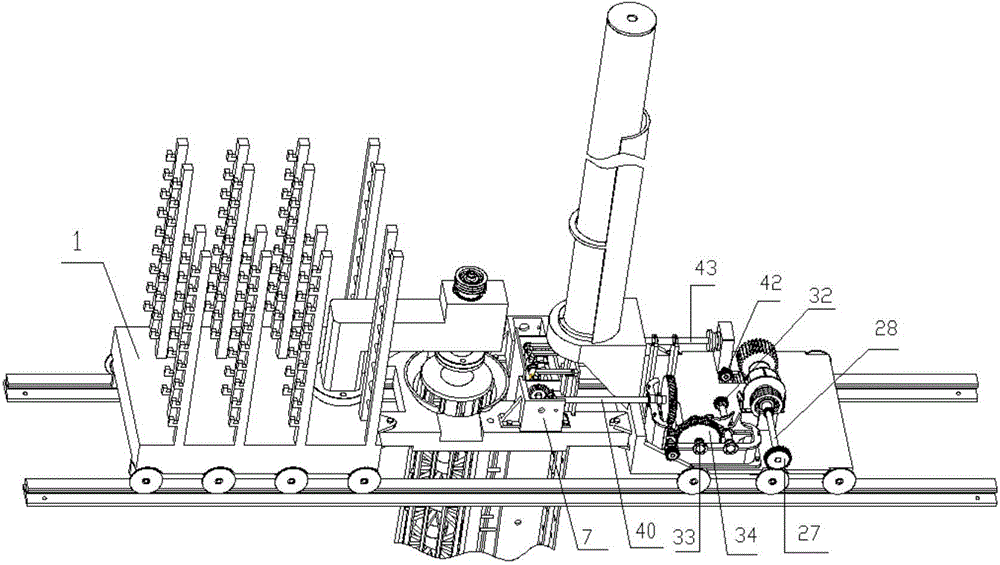

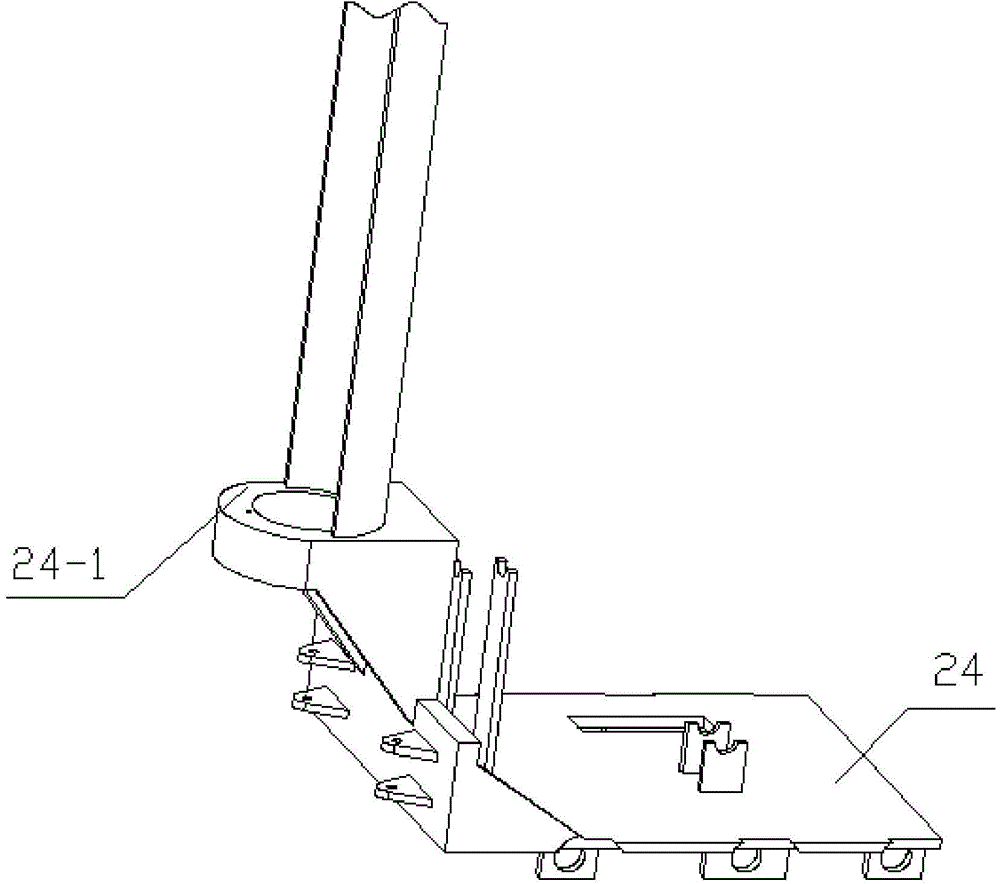

[0034] Such as figure 1 and 2 As shown, a method for fully automatic interweaving of steel mesh for underground diaphragm walls, the specific steps are as follows:

[0035] Step 1: Put steel bars into the longitudinal steel bar conveying mechanism, and connect the high-pressure water pipe to the high-pressure water input hole of the groove milling mechanism.

[0036] Step 2: The driving mechanism drives the groove milling bit of the groove milling mechanism to dig out the initial groove section of the continuous wall guide wall groove. When the groove milling bit digs the guide wall groove of the continuous wall, high-pressure water is sprayed from the outlet hole of the groove milling bit to disperse the soil on the side wall that has not been excavated, and the soil slag after cutting can be pumped out of the ground by a water pump.

[0037] Step 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com