Injection device and method for evaluating breathability recovery capability of filter bag

A recovery ability, injection device technology, applied in the direction of measuring devices, separation methods, chemical instruments and methods, etc., can solve the problems of late service start, lack of pre-assessment method test devices, immaturity, etc., to avoid damage, structure Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

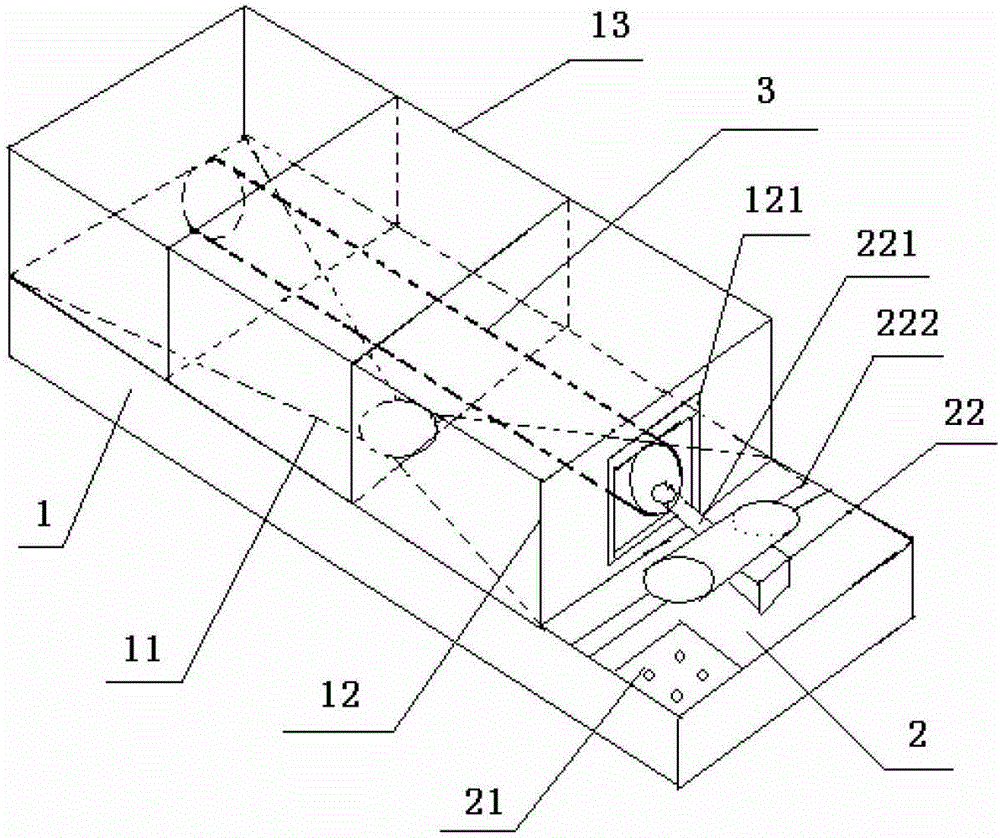

[0029] Such as figure 1 As shown, the present invention is an injection device for evaluating the air permeability recovery ability of a filter bag, which includes an injection platform 1 and an operation platform 2 arranged on one side of the injection platform 1 .

[0030] The blowing platform 1 is fixed with an ash hopper 11 for collecting dust and ash discharge, a bracket 12 for fixing samples, and a dust collection cover 13 for collecting dust and pressure relief. The dust collection cover 13 is set on the bracket 12 and The ash hopper 11 is covered inside, and the bracket 12 is provided with a flower plate slot 121, which is a flower plate fixing device, and can be installed with different specifications of flower plates, so as to realize the wide application of filter bags of different specifications Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com