Automatic analysis apparatus and automatic analysis method

An automatic analysis device and analysis reagent technology, applied in the direction of analysis materials, instruments, etc., can solve the problems of reducing the sensitivity and measurement range of test items, limiting test flexibility, and large instrument volume, so as to achieve high-speed testing, easy high-speed testing, The effect of reducing the volume of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

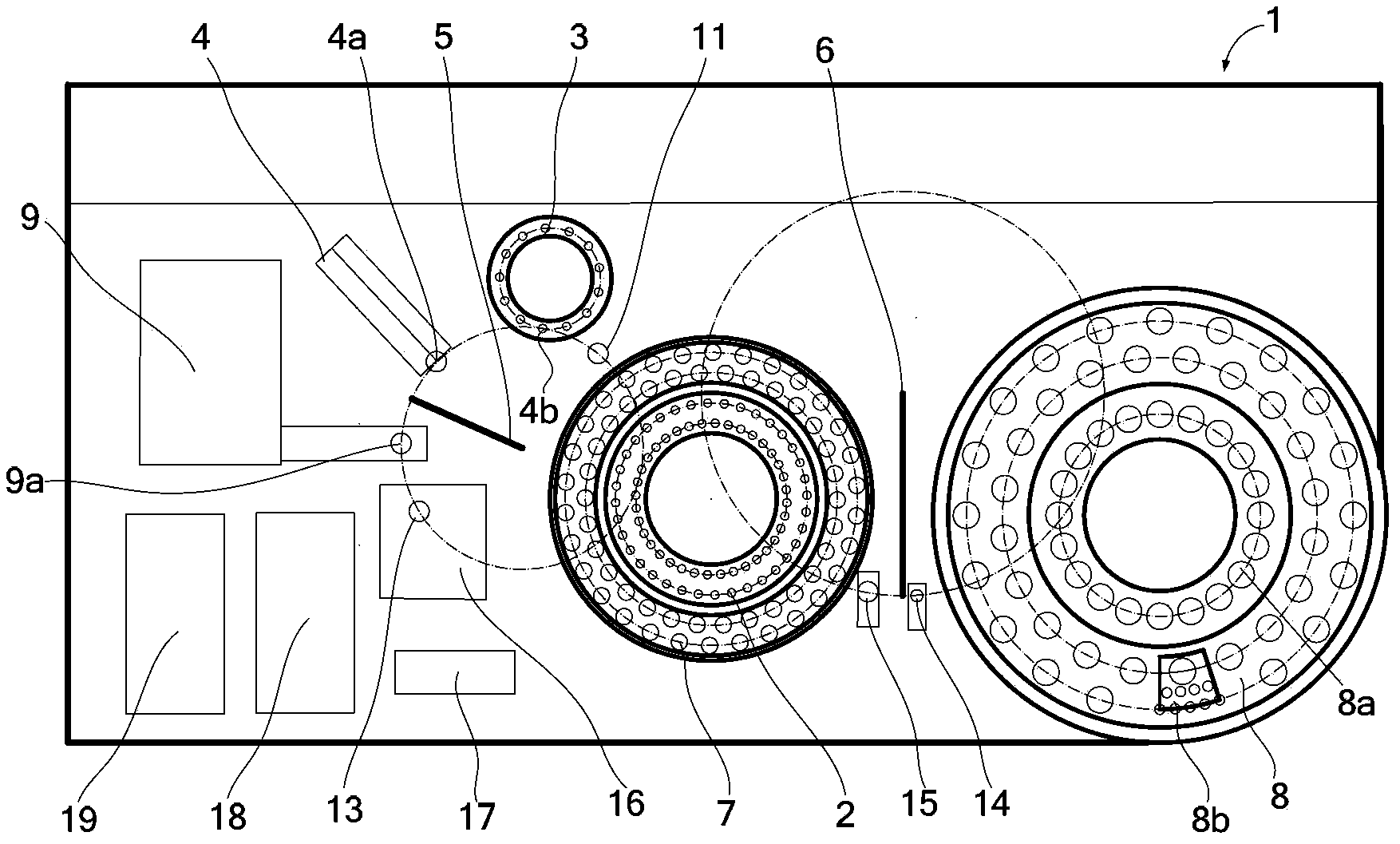

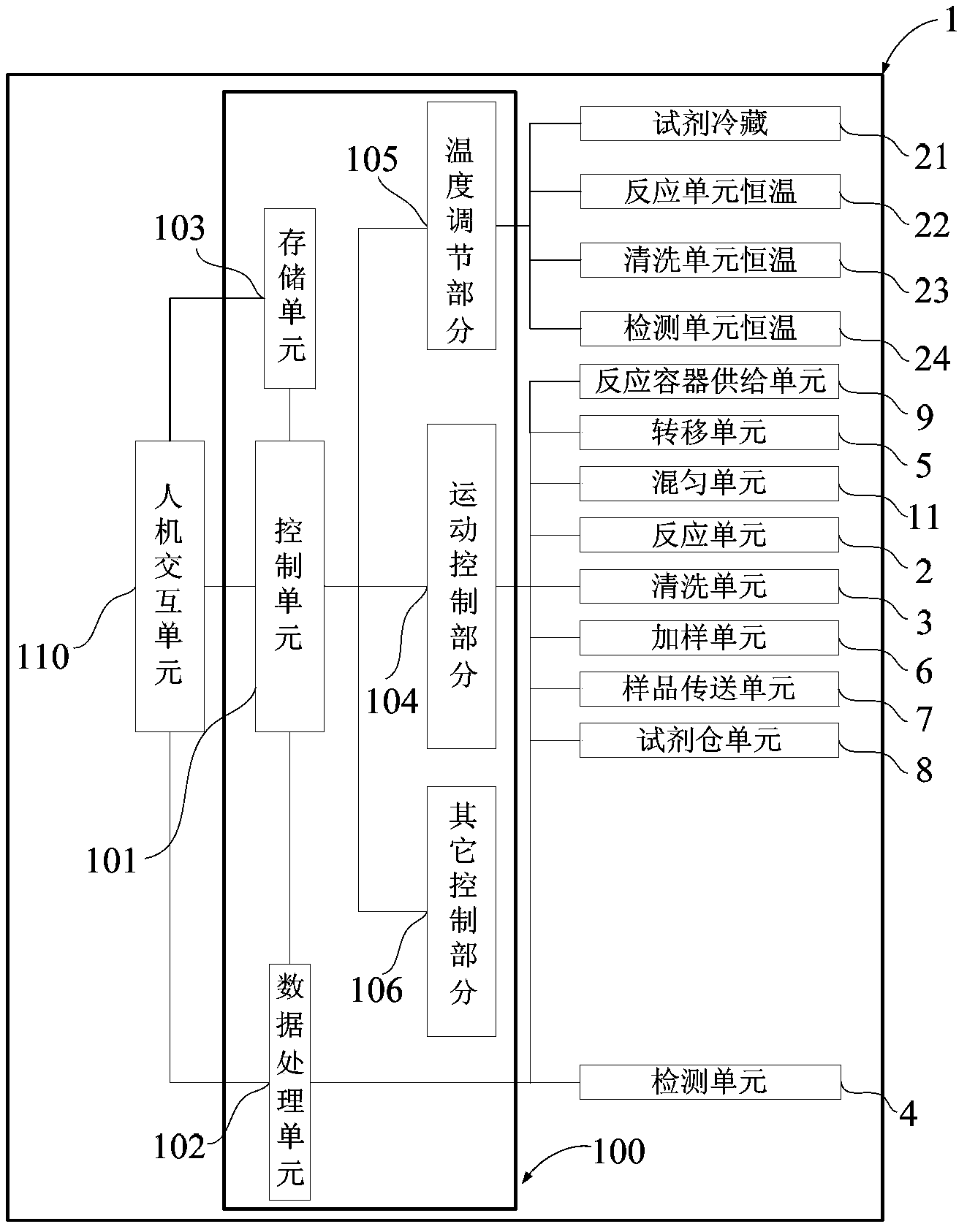

[0058] Embodiment one: see attached figure 1 shown.

[0059] An automatic analysis device 1, which includes a reaction container supply unit 9, a reagent chamber unit 8, a sample transfer unit 7, a reaction incubation unit 2, a cleaning and separation unit 3, a detection unit 4, a sample adding unit 6, a transfer unit 5, a control unit The system 100 includes a mixing unit 11 , a cleaning device, a reaction container recovery area 16 , a detection reagent loading area 17 , a waste liquid recovery area 18 , and a liquid supply area 19 .

[0060] Each part is described in detail below.

[0061] The reaction container supply unit 9 is used for accommodating and providing the reaction containers required for the analysis test, wherein several reaction containers are placed, and the reaction container supply unit 9 has a container supply position. For example, the reaction container supply unit 9 accommodates 1000 reaction containers at a time. In order to reduce the contaminatio...

Embodiment approach

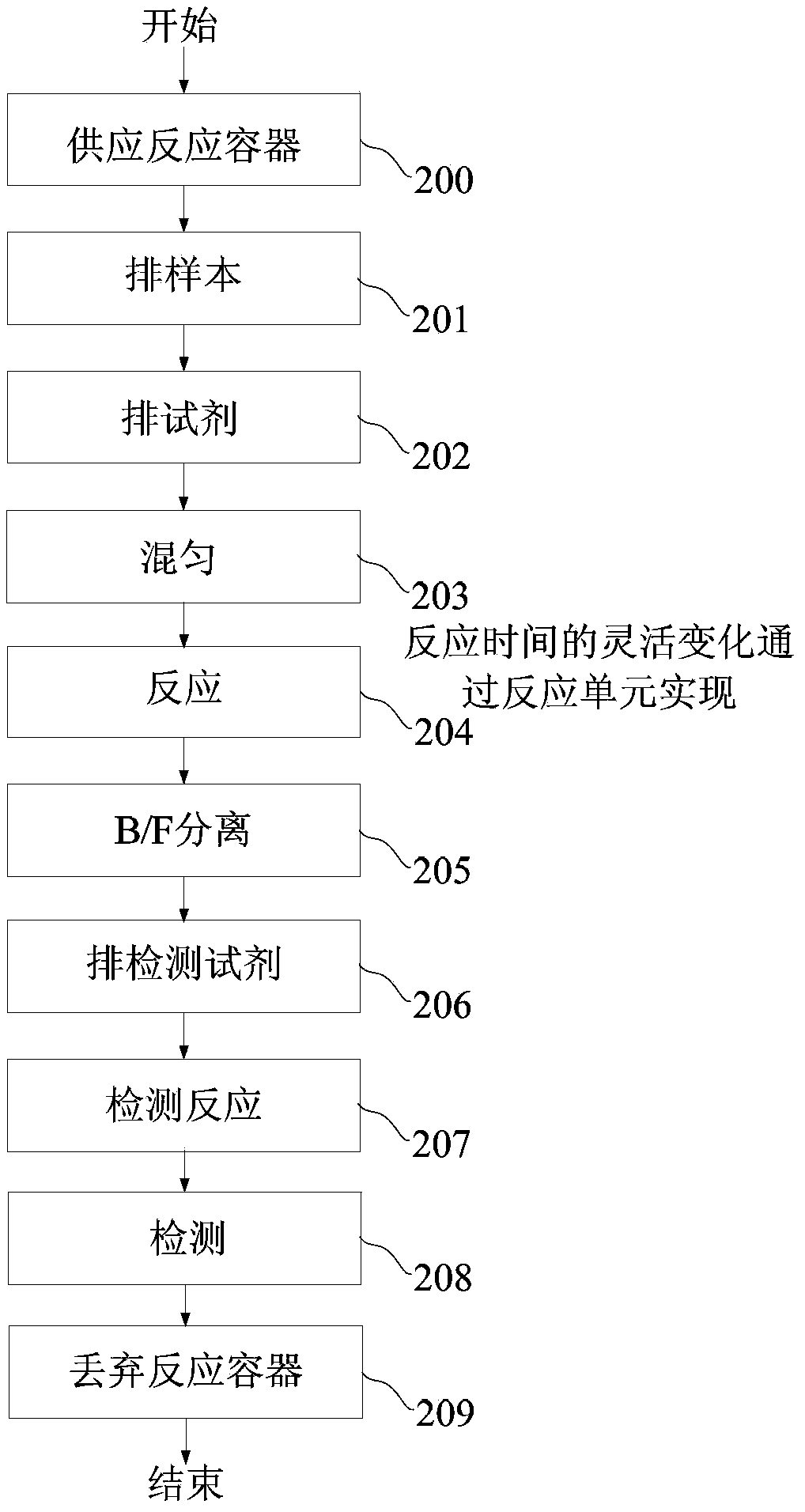

[0069] The first embodiment is as figure 1 As shown: the injection of the detection reagent after cleaning and separation can be completed on the cleaning and separation unit 3, that is, in this embodiment, the detection reaction incubation position of the detection unit 4 is integrated in the cleaning and separation unit 3, and the detection reaction incubation position corresponds to A detection reagent injection mechanism is provided. After the detection reagent injection mechanism injects the detection reagent into the reaction container, the detection reaction is completed at the detection reaction incubation position on the cleaning separation unit 3, and the reaction usually takes several minutes, such as 3 minutes. In this way, the resources on the cleaning and separation unit 3 can be fully utilized and cost saved.

[0070] The second embodiment is as Figure 10 Shown: the detection reaction incubation position of the detection unit 4 is located on an independent de...

Embodiment 2

[0111] Embodiment two: see attached Figure 7 shown, with figure 1 Compared with the first embodiment shown, the difference lies in the sample adding unit 6 and the cleaning unit. The horizontal trajectory of the sample loading unit 6 is a straight line, which can move along the horizontal linear guide rail and vertically up and down. The horizontal trajectory intersects the sample transfer unit 7, the reaction incubation unit 2 and the reagent chamber unit 8 respectively. The horizontal movement of the sample adding unit 6 can improve the positioning accuracy, and can also make the whole machine more compact. The cleaning unit changes from a single circle to at least one circle. In this embodiment, the cleaning and separation unit 3 has two circles, the inner circle 3a completes the cleaning and separation and the dispensing of detection liquid, and the outer circle 3b completes the detection reaction, so that the functional division is more independent The cleaning, separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com