wind power plant

A technology for wind power generation devices and power generation components, which is applied in wind power generation, wind turbines, wind turbine combinations, etc., can solve the problems of wind energy waste, low wind energy collection efficiency, etc., and achieves small size, easy high-density integration, and reduced size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the purpose, structure and function of the present invention, a wind power generation device of the present invention will be described in further detail below with reference to the accompanying drawings.

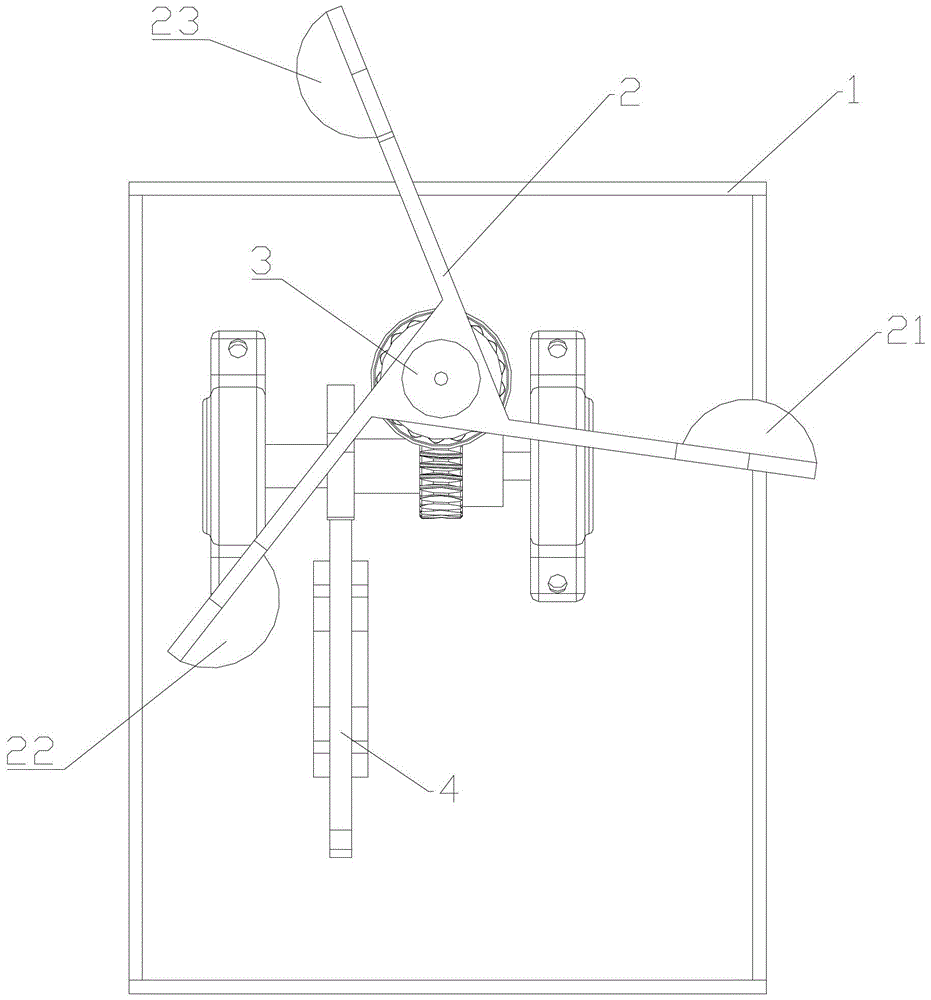

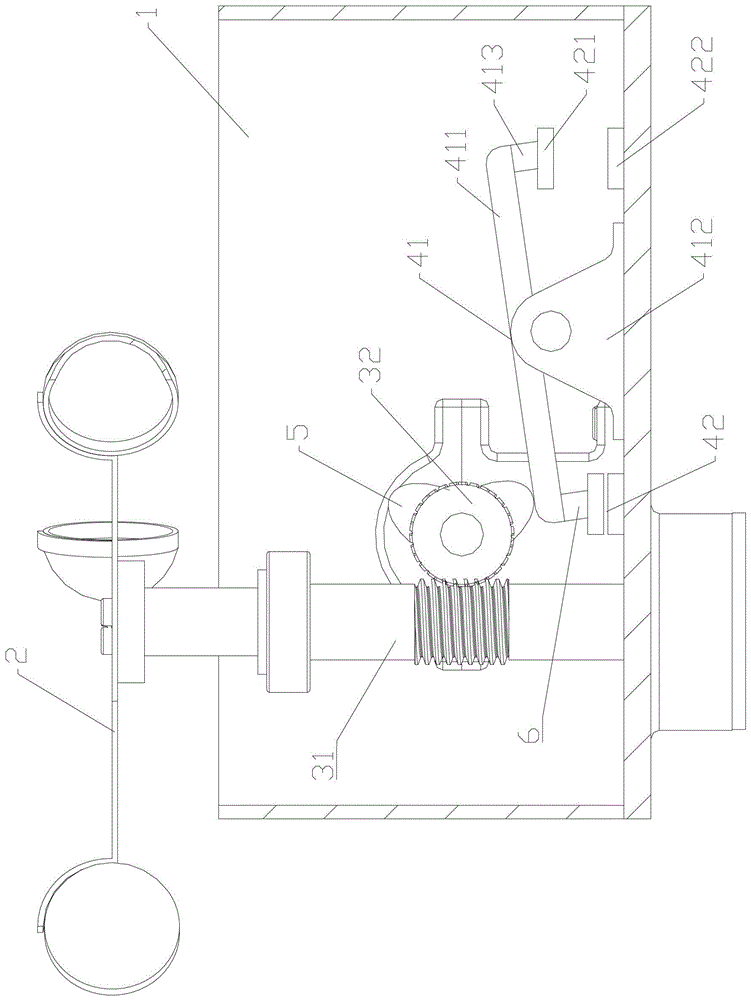

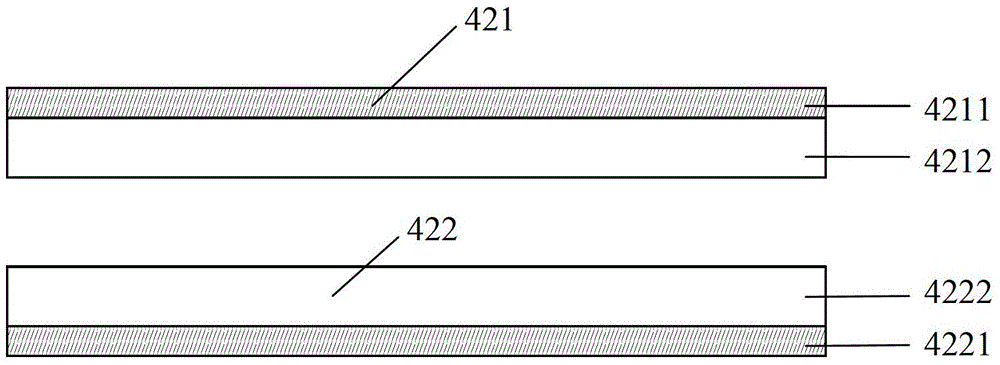

[0018] like figure 1 and figure 2 shown, it shows a first embodiment of the wind power plant of the present invention. In this embodiment, the wind power generation device includes a body 1 and a wind energy receiving assembly 2 , a transmission assembly 3 , and a power generation assembly 4 arranged in the body 1 . The wind energy receiving assembly 2 is connected with the power generation assembly 4 through the transmission assembly 3 . During operation, the wind energy receiving component 2 is used to convert the wind energy in the environment into mechanical energy, and transmit the mechanical energy to the power generating component 4 through the transmission component 3 , and then convert the mechanical energy into electrical ene...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap