Cam carrier assemblies for internal combustion engines

An internal combustion engine and cam technology, which is applied to engine components, engine testing, machine/engine, etc., can solve the problems of non-optimal accuracy, low output signal of cam sensor, etc., to improve accuracy, easy assembly, and simple installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0122] Exemplary embodiments will now be described with reference to the accompanying drawings, which are not intended to limit application and use.

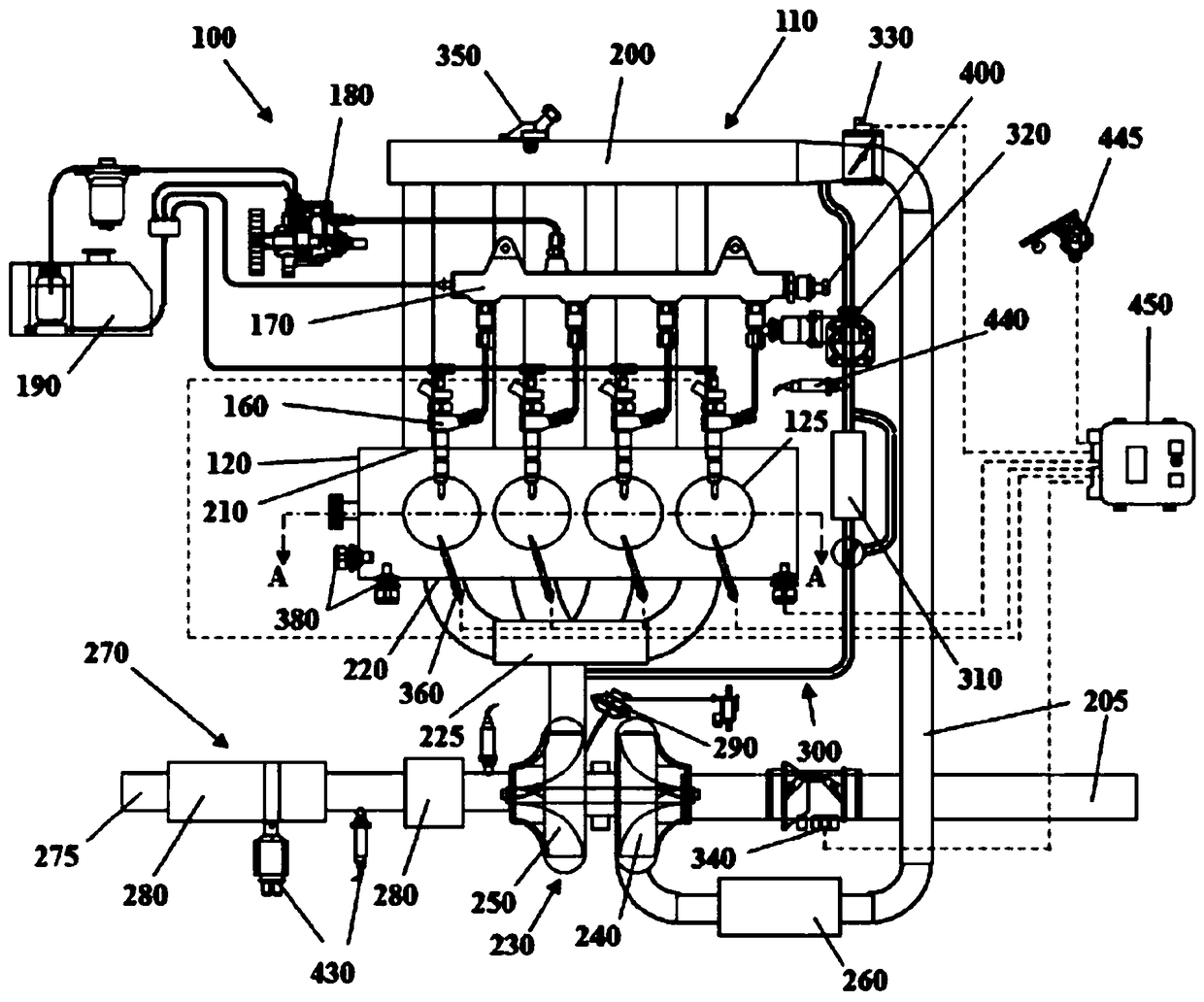

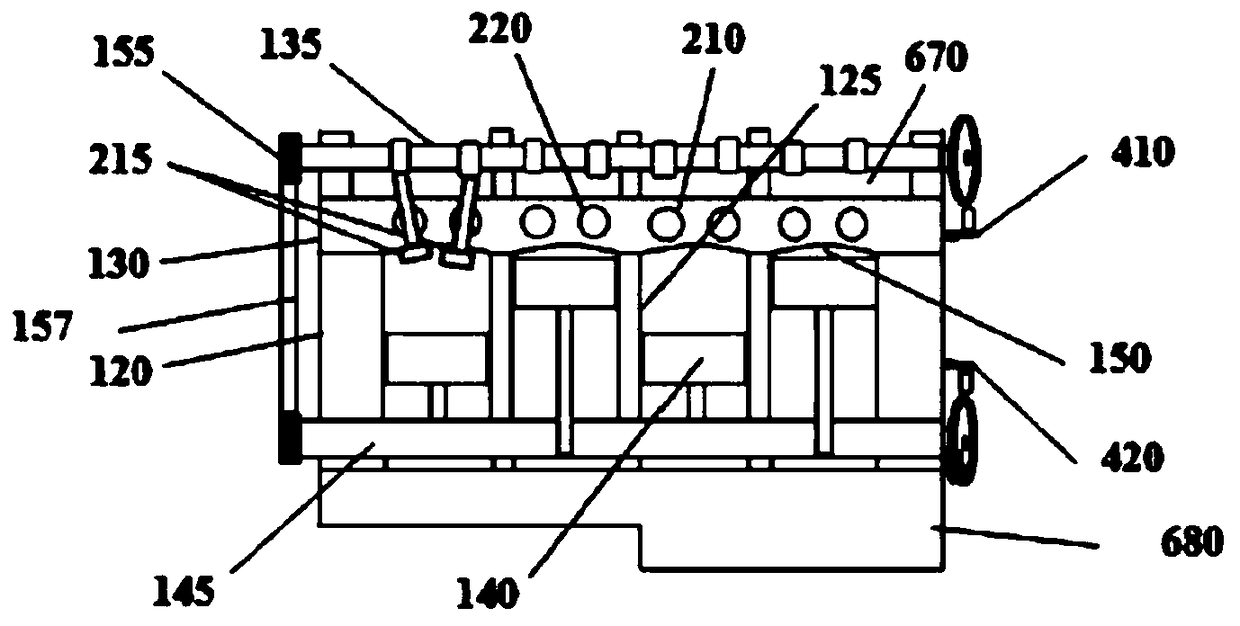

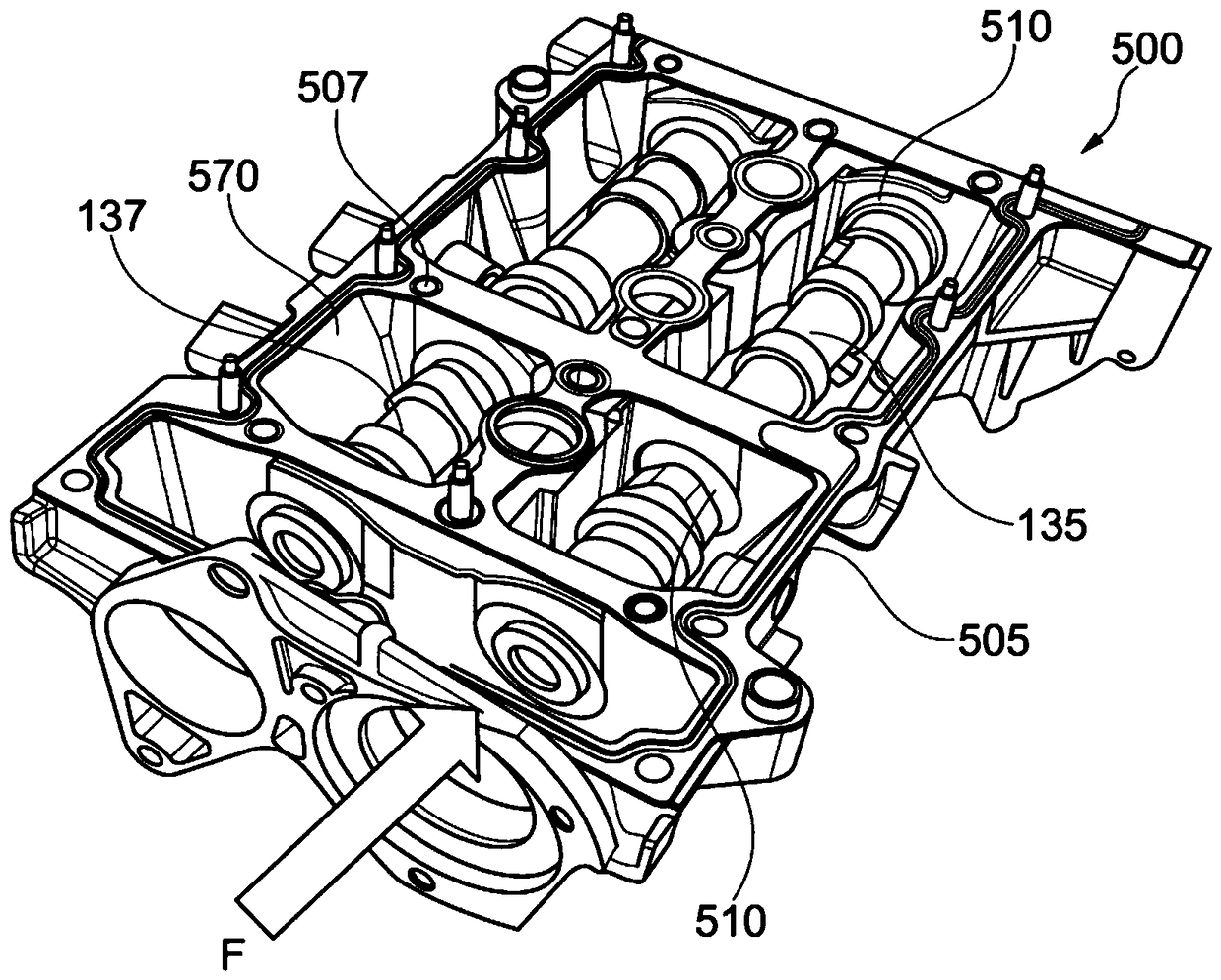

[0123] Some embodiments may include automotive systems 100 such as figure 1 with 2 As shown in , the automotive system 100 includes an internal combustion engine (ICE) 110 having an engine block 120 defining at least one cylinder 125 having a piston 140 held by Coupled to rotate crankshaft 145 housed in crankcase 680 . Cylinder head 130 cooperates with piston 140 to define combustion chamber 150 . A fuel and air mixture (not shown) is disposed in combustion chamber 150 and ignited such that thermally expanding exhaust gases cause reciprocating motion of piston 140 . Fuel is provided by at least one fuel injector 160 and air passing through at least one intake port 210 . Fuel is provided to fuel injector 160 at high pressure from fuel rail 170 in fluid communication with a high pressure fuel pump 180 that increases the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com