Textile machinery and the processing method of element eigenvalues of fiber machinery

A technology of eigenvalues and fibers, which is applied in thin material processing, textiles and papermaking, and conveying filamentous materials, etc. It can solve problems such as unit eigenvalue processing without consideration, and achieve the effect of easy write-back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

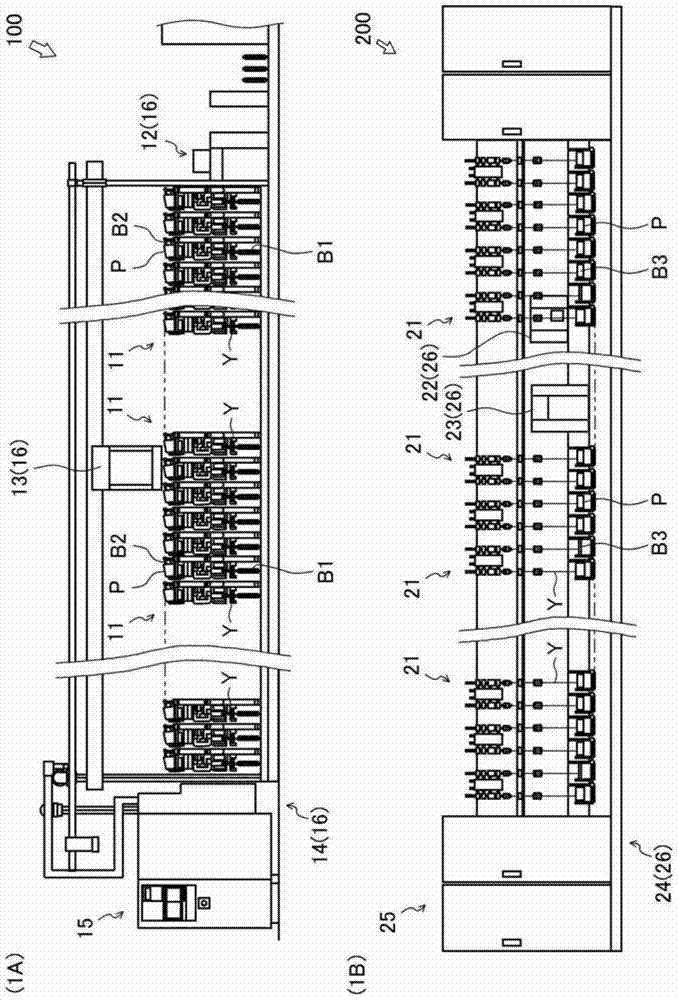

[0032] First, an automatic winder 100 as an example of a typical textile machine will be briefly described.

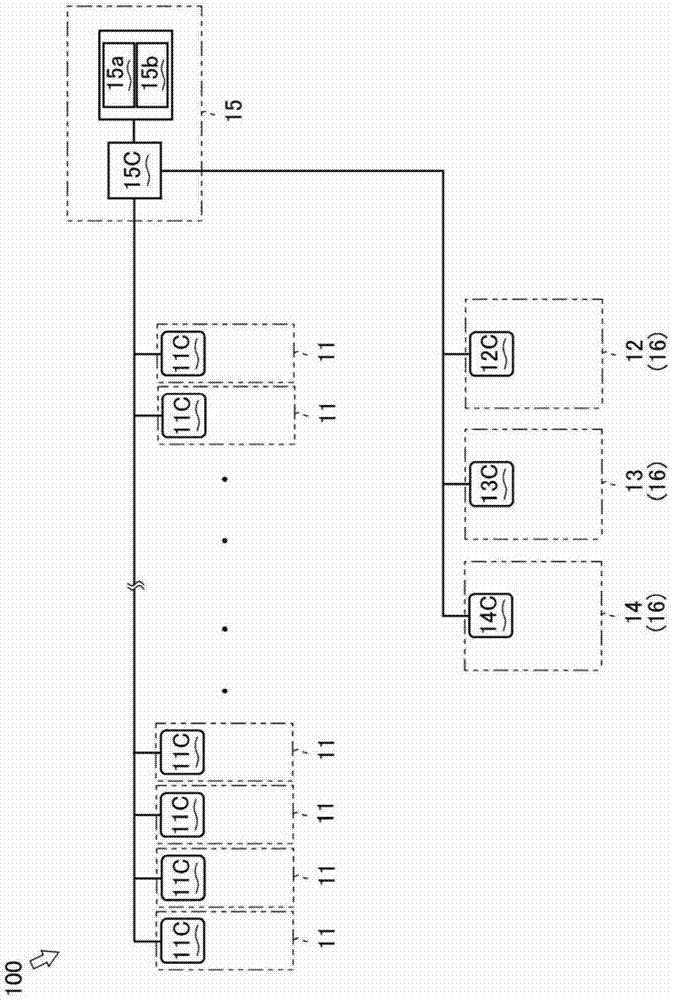

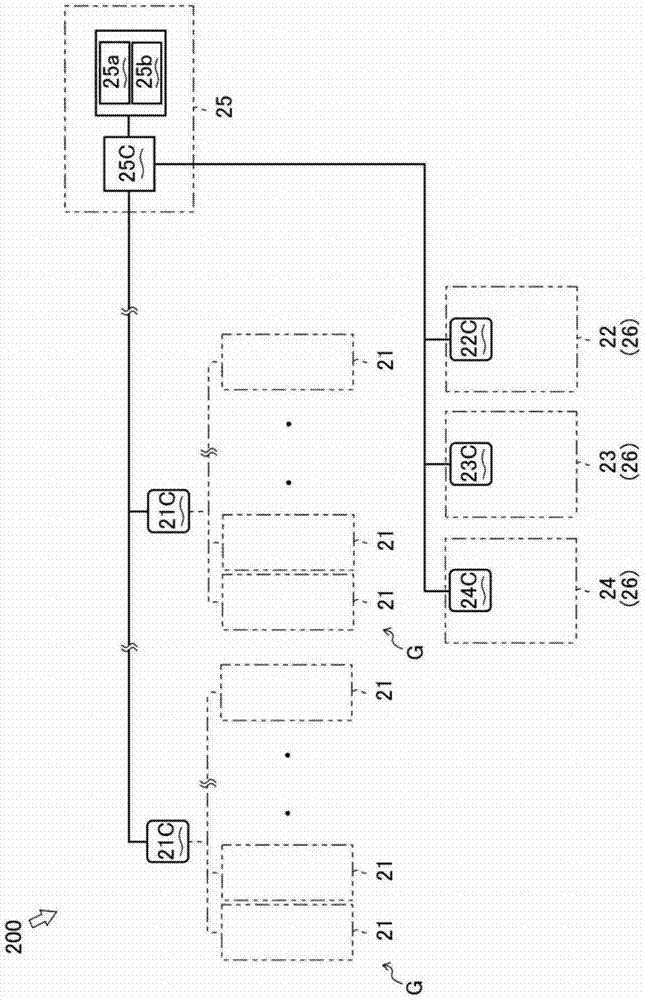

[0033] figure 1 A shows the overall structure of the automatic winder 100 . in addition, figure 2 The communication system of the automatic winder 100 is shown.

[0034] The automatic winder 100 is mainly composed of a plurality of processing units 11 , a bobbin preparation device 12 , a doffing device 13 , an auxiliary device 14 , and an overall control device 15 . Multiple processing units 11 are arranged side by side along the long side direction of the chassis.

[0035] When a yarn defect is found in the yarn Y unwound from the yarn supplying bobbin B1, the processing unit 11 adjusts the yarn quality by removing the yarn defect. Then, the processing unit 11 rotates the winding bobbin B2 to wind the yarn Y, thereby forming a package P on the winding bobbin B2. In this way, the processing unit 11 is a winding unit that adjusts the yarn quality of the yarn Y and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com