Printing quality evaluation and process control method

A technology of printing quality and process control, which is applied to general parts of printing machinery, printing, printing machines, etc., and can solve problems such as not giving operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

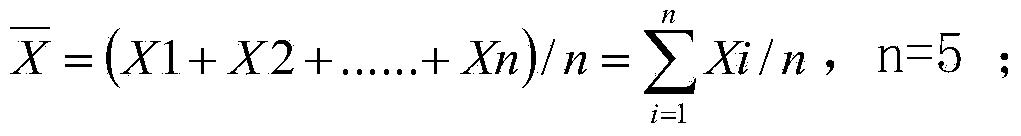

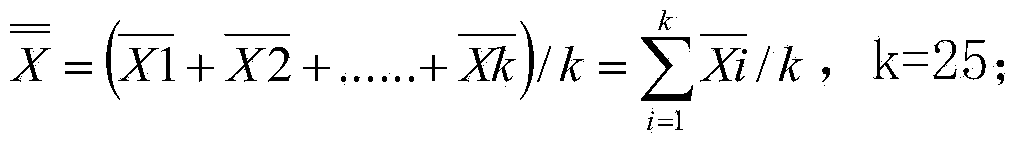

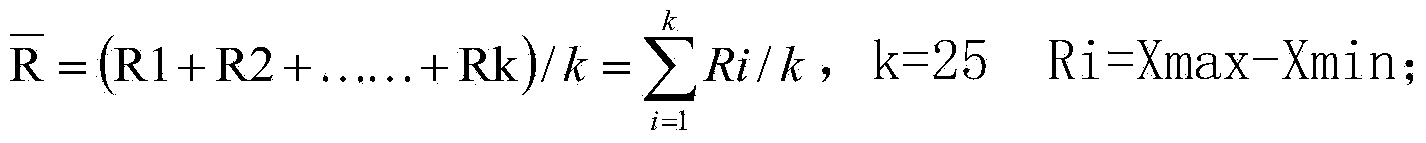

[0062] A printing quality evaluation and process control method, the method includes the establishment of enterprise production standards and printing process control two parts.

[0063] (1) The method of establishing enterprise production standards is as follows:

[0064] (1) On the basis of normal and standardized printing conditions, print standard proofs. The printed content includes: C, M, Y, K solid color blocks (in the form of measurement and control strips, printed on the jaws of the standard proofs), CM , MY, CY overprinted color blocks (in the form of measurement and control strips, printed on the mouth of the standard proof), C, M, Y, K four-color 25%, 50%, 75% dot color blocks (in the form of measurement and control strips, printed At the jaw position of the standard proof sheet), C, M, Y, K four colors 2%, 4%, 6%, 8%, 10%, 20%, 30%, 40%, 50%, 60%, 70% , 80%, 90% dot tone patches (color patches with more dot tone values can be added, and the chromaticity measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com