Assembling tooling simultaneously applicable to die-cutting machine and gilding press

A technology for assembling tooling and bronzing machine, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of loss of working area, complicated handling, low assembly efficiency, etc., to optimize the use of factory area, simple tooling structure, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

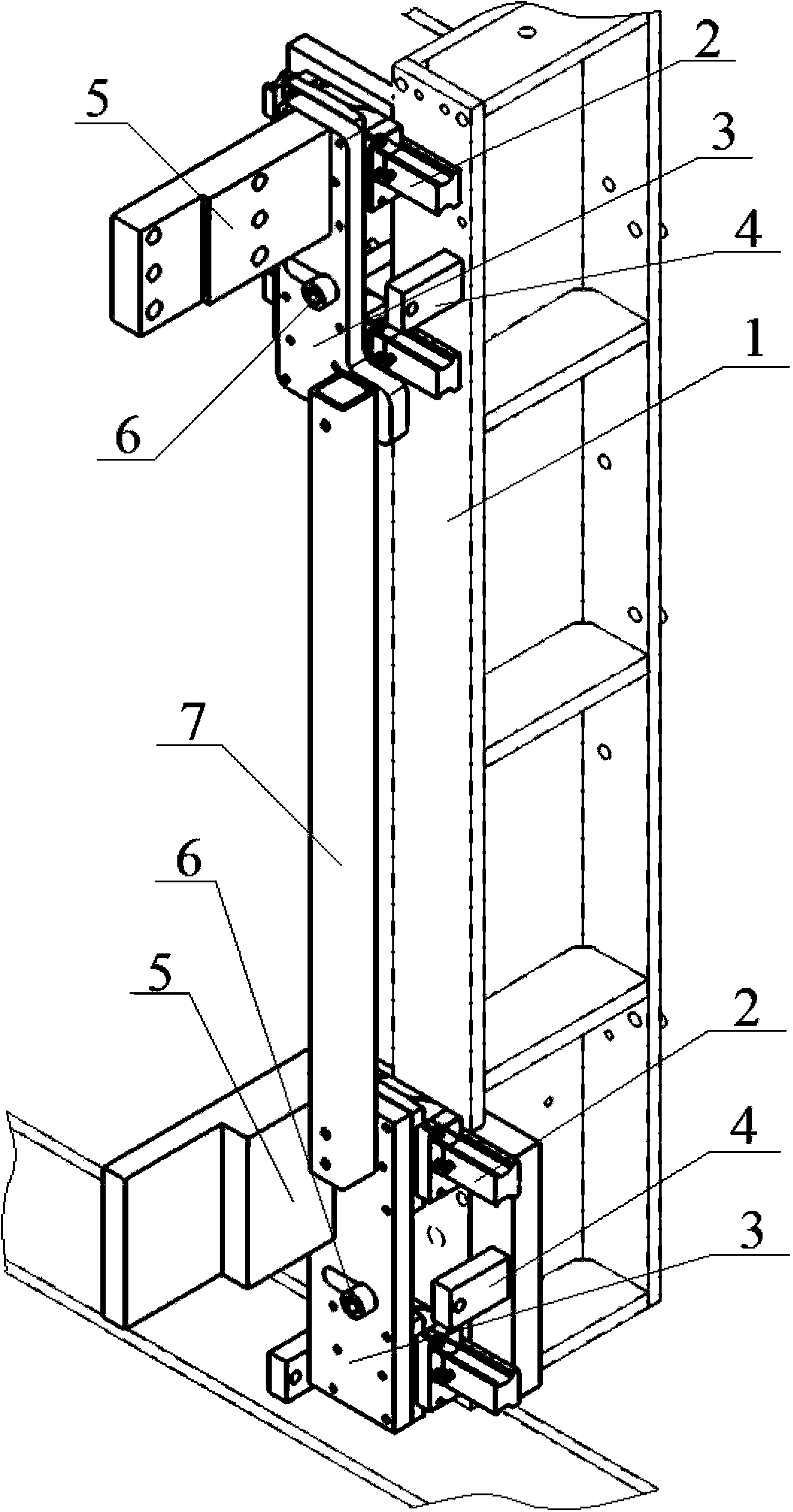

[0025] An assembly tool suitable for both die-cutters and hot stamping machines, such as figure 1 As shown, including bracket 1, linear guide rail 2, slider 3, fixed block 5 and connecting rod 7, there are 4 linear guide rails 2 in total, 2 of which are fixed on the upper end of bracket 1, and the other 2 are fixed on the bottom of bracket 1. At the lower end, there are two sliders 3, which are respectively slidably connected to the linear guide rails 2 located at the upper and lower ends of the support 1. There are two fixed blocks 5, which are respectively vertically fixed on the slider 3. The fixed block 5 is a stepped body, fixed Block 5 is provided with mounting holes for installing machine wall panels. The connecting rod 7 is fixedly connected between the two sliders 3 and constrains the two sliders 3 to move synchronously. A limiting block 4 for limiting the sliding position of the slider 3 is provided between the two linear guide rails 2 located at the upper and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com