Space water droplet positioning substrate and preparation method thereof

A positioning-based, water-based technology, applied in separation methods, chemical instruments and methods, evaporation, etc., to achieve the effects of simple and effective preparation method, precise size, and controllable structure of alternating hydrophilic and hydrophobic regions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

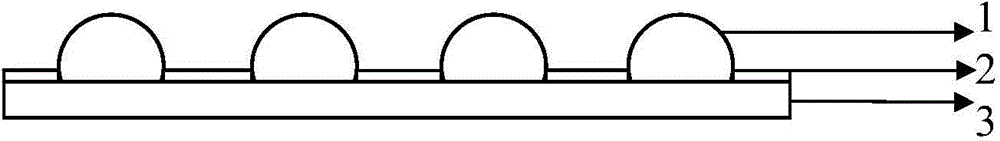

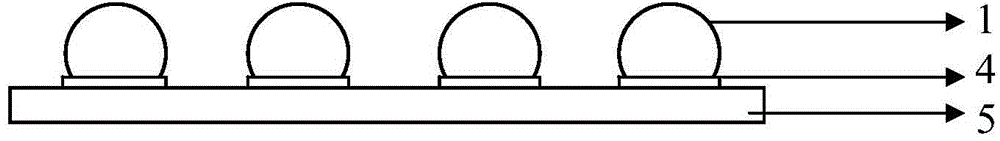

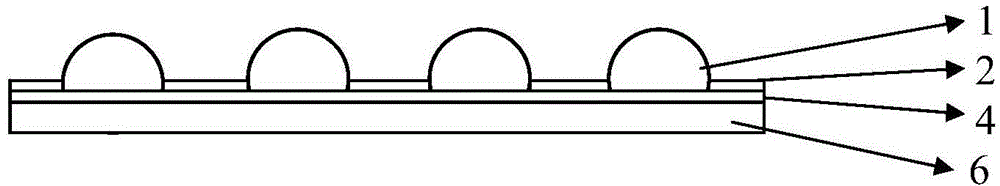

[0037] The present invention provides as attached figure 1 A spatial water-based droplet positioning substrate is shown, the surface of the substrate is a thin film with alternating structure of hydrophilic regions and hydrophobic regions; the shape of the hydrophilic region can be designed into any geometric shape, and the hydrophobic region will be hydrophilic Surrounded by the area, it plays the role of confining the water-based liquid droplets 1 .

[0038] The positioning substrate is divided into two layers, namely the hydrophilic substrate 3 and the hydrophobic film 2 covering the hydrophilic substrate 3, the hydrophobic film 2 does not completely cover the hydrophilic substrate 3; the hydrophilic area is the exposed area of the hydrophilic substrate 3, and the hydrophobic film 2 covers the hydrophilic substrate 3; The area is the area covered by the hydrophobic membrane 2.

[0039] The invention provides a method for preparing a spatial water-based droplet positionin...

Embodiment 2

[0050] The present invention provides as attached figure 1 Another shown spatial water-based droplet positioning substrate differs from Embodiment 1 in that:

[0051] In this embodiment, the hydrophilic substrate is a quartz plate, and the covering method adopts an aluminum film covering method. Specific steps are as follows:

[0052] (1) Clean the hydrophilic substrate: clean the surface of the quartz slice with detergent first, then place it in an acetone solution for ultrasonic cleaning for 30-60 minutes, take out the quartz slice after ultrasonication, and wash it repeatedly with absolute ethanol and deionized water until it is clean . In this embodiment, the length, width, and height of the base material are selected as 25mm*80mm*1mm, but the size of the base in the present invention is not limited to this, and can be adjusted as required.

[0053] (2) Covering film preparation: This implementation adopts the aluminum film covering method. In this embodiment, the func...

Embodiment 3

[0058] The present invention provides as attached figure 1 Another shown spatial water-based droplet positioning substrate differs from Embodiment 1 in that:

[0059] In this embodiment, the hydrophilic substrate is a silicon wafer, the covering method adopts a photoresist covering method, and the photoresist adopts reverse glue. Specific steps are as follows:

[0060] (1) Clean the hydrophilic substrate: clean the surface of the silicon wafer with detergent first, then place it in an acetone solution for ultrasonic cleaning for 30-60 minutes, take out the silicon wafer after ultrasonication, and wash it repeatedly with absolute ethanol and deionized water until it is clean . In this embodiment, the length, width, and height of the base material are selected as 25mm*80mm*1mm, but the size of the base in the present invention is not limited to this, and can be adjusted as required.

[0061] (2) Preparation of covering film: In this embodiment, a photoresist covering method i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com