Intelligent self-identification pay recycling machine for waste batteries

A waste battery and battery recycling technology, which is applied in the direction of starting with a returnable container, can solve the problem of judging whether an object that cannot be put in is a battery, etc., and achieve the effects of remote management and control, avoiding environmental pollution, and preventing malicious damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

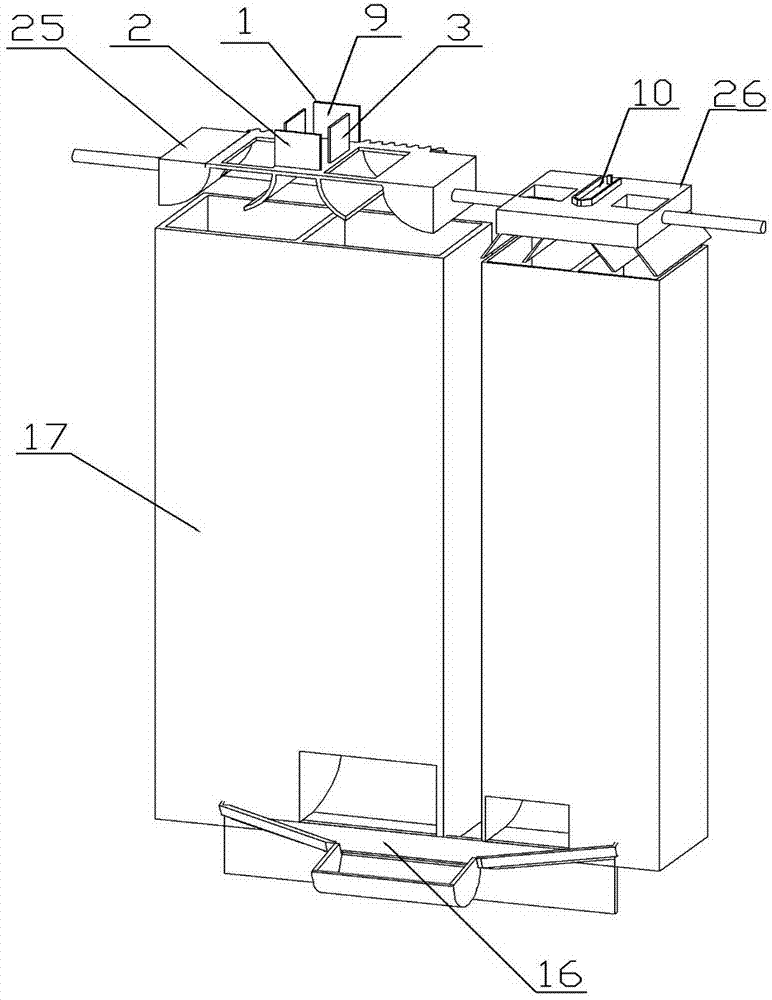

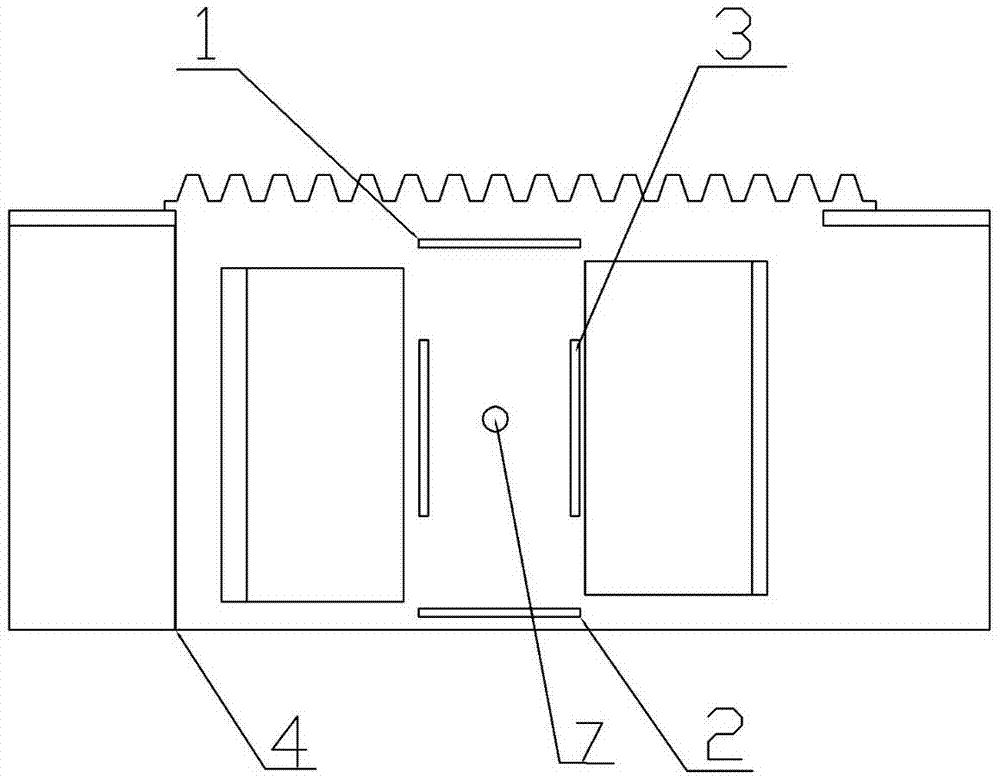

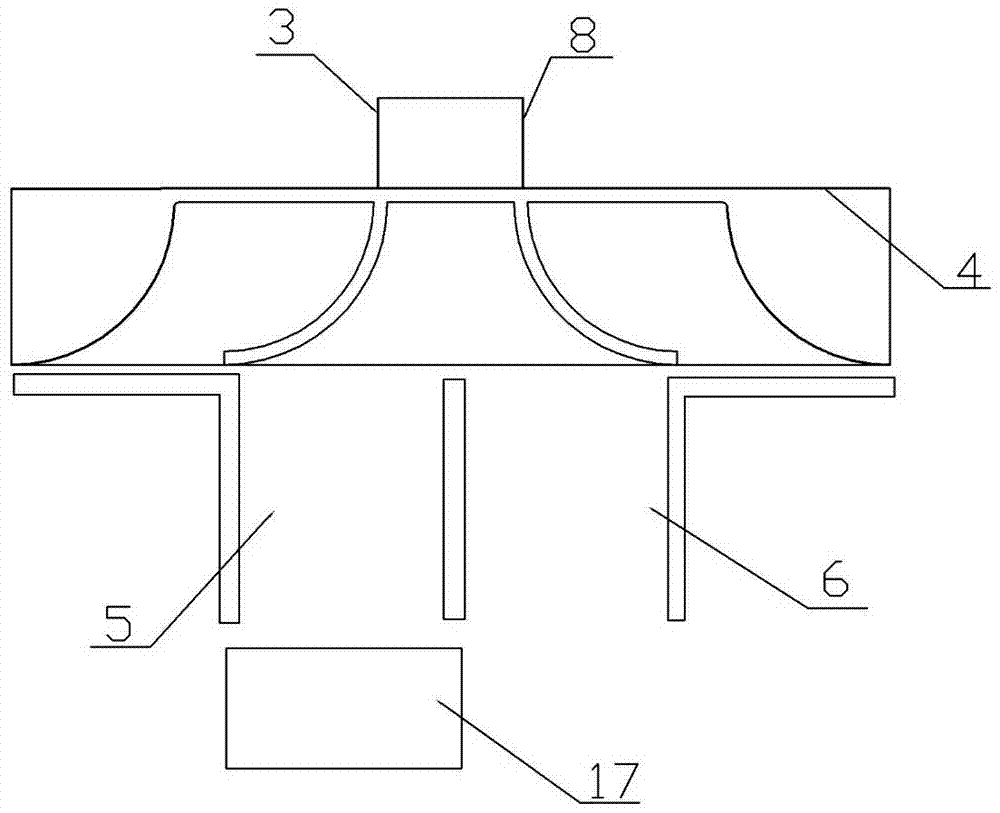

[0028] Embodiment 1 An intelligent waste battery self-identification payment recycling machine, see Figure 1-8 , including waste battery intelligent identification module, waste battery classification collection module, coin value setting and coin output module, stepper motor drive and power control module, control module, touch screen, real-time monitoring camera, network interface module, old battery collection The device includes a battery recycling box 17, a button battery testing bin 10 installed above the battery recycling bin 17, a non-button battery testing bin 9 and corresponding mobile racks 25, 26, and each battery testing bin includes a door and a bottom baffle plate. 4. Insulated width measuring push plate 3, length measuring push plate 1, end fixing plate 8, side fixing plate, warehouse door, warehouse bottom baffle 4, insulating width measuring push plate 3, length measuring push plate 1, mobile frame Corresponding drive stepping motors are respectively provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com