Gob retardant efficient spraying system and spraying method

A spraying system and inhibitor technology, applied in mining equipment, earthwork drilling, safety devices, etc., to achieve the effects of optimizing technical methods, improving safety, and avoiding hidden dangers of spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

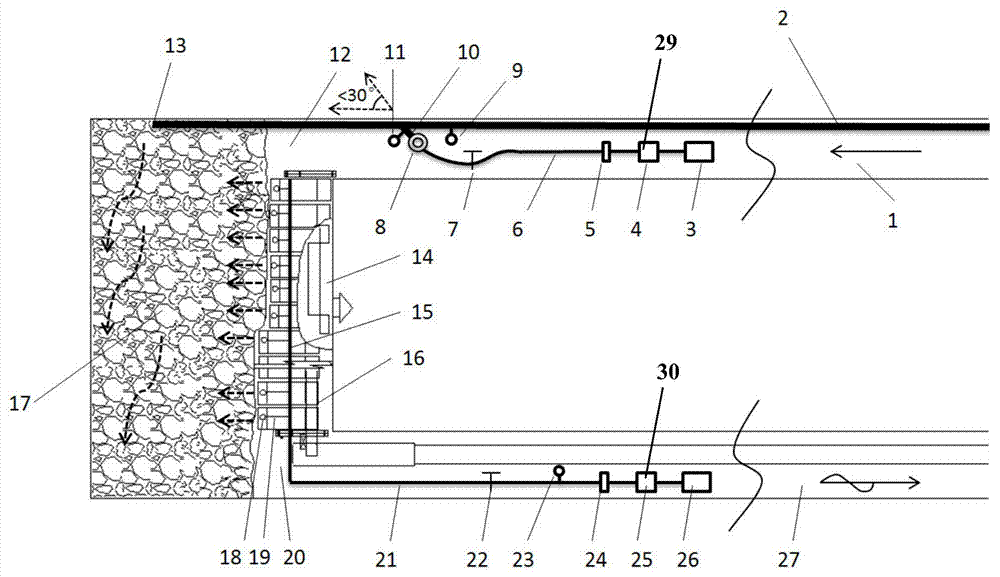

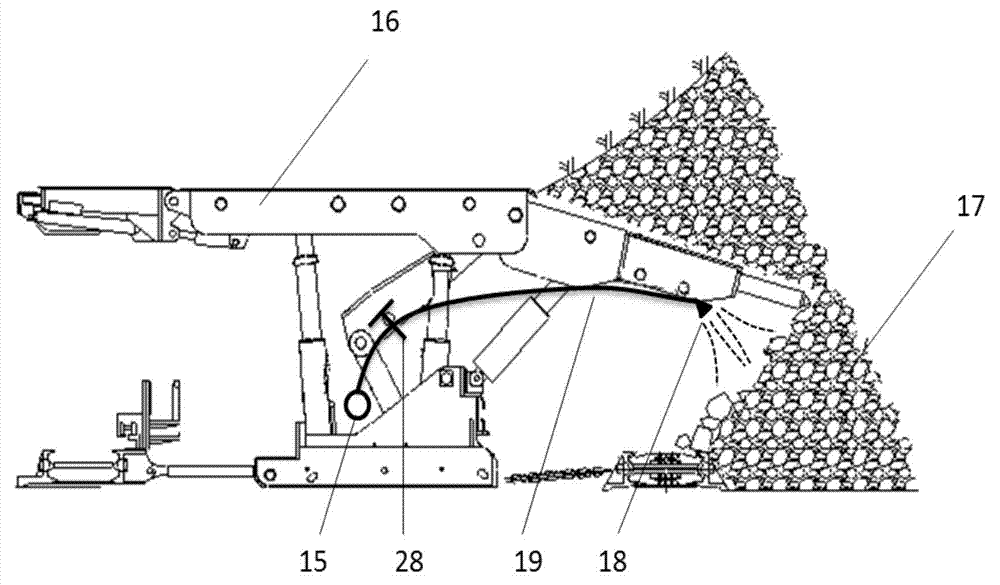

[0038] Below in conjunction with accompanying drawing and certain coal mine 28412 fully mechanized caving working face examples the present invention is described in further detail.

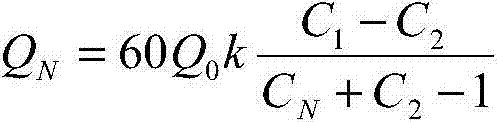

[0039] Such as figure 1 , figure 2As shown, a goaf inhibitor efficient spraying system includes the first inhibitory pumping station 29 arranged at 100 meters away from the lower corner 12 of the air inlet roadway, and the first resistive chemical pump station 29 arranged at the upper corner 20 meters away from the return airway 27. The second resistance chemical pump station 30 at one hundred meters and the nitrogen delivery pipeline 2 arranged at the air inlet lane 1; the first resistance chemical pump station 29 consists of the first liquid storage tank 3, the first resistance chemical pump 4, the first The filter 5 and the first high-pressure ball valve 7 are composed, the first liquid storage tank 3 is connected with the input end of the first resistance pump 4, and the output end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com