Granular cotton production line

A production line and granular cotton technology, applied in glass manufacturing equipment, manufacturing tools, etc., to achieve the effect of promoting formation, improving fiber formation rate and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

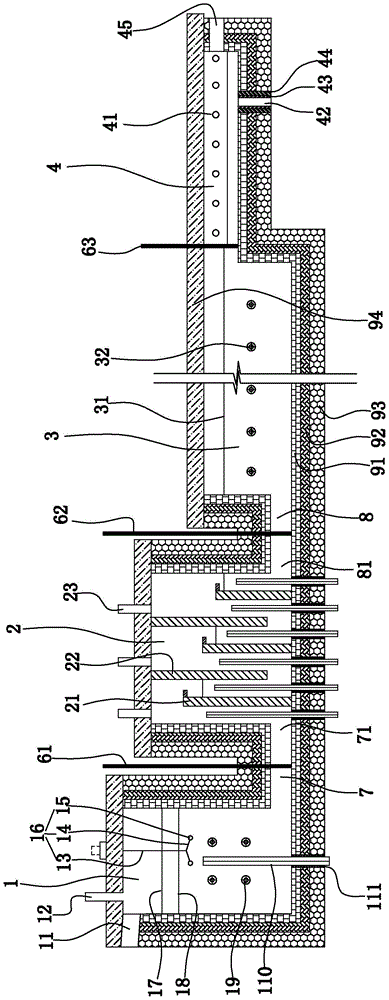

[0051] Such as figure 1 Shown, a kind of granular cotton production line comprises the slag ditch 1a that is used to divert hot state slag of blast furnace, slag furnace, centrifuge 5, cotton collector and granulator; Wherein cotton collector and granulator are existing have technology.

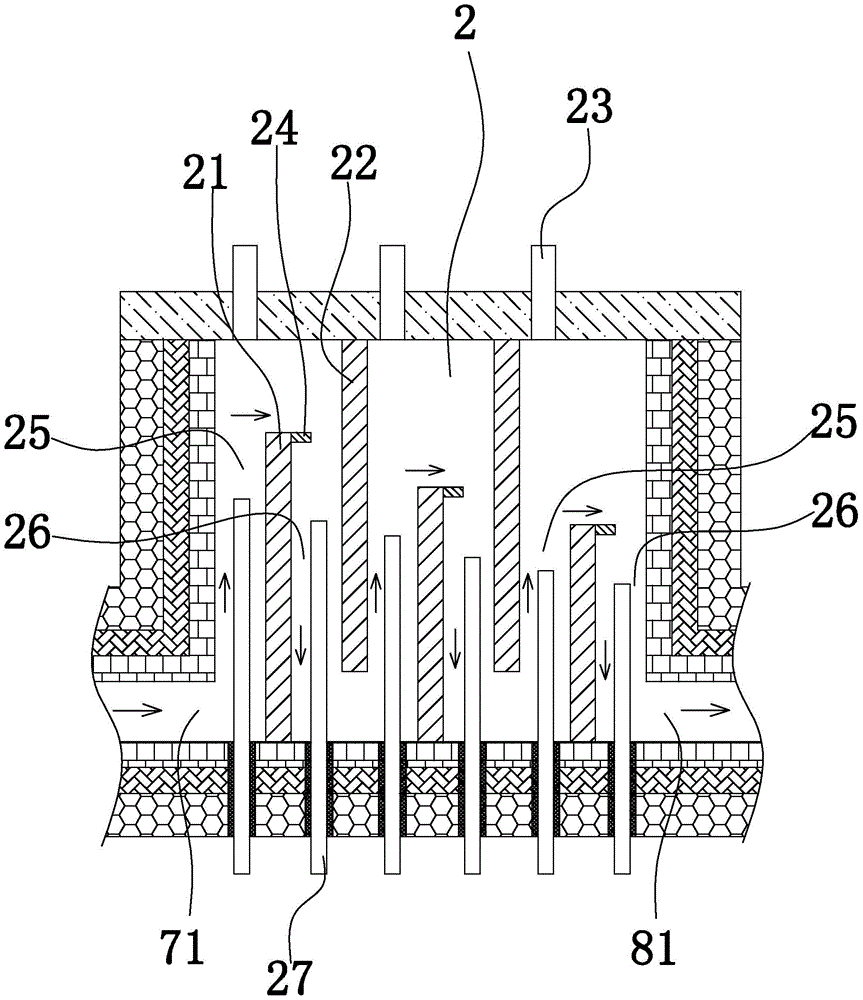

[0052] Such as figure 1 , As shown in 2, the slag furnace includes a feeding pool 1, a homogenizing pool 2, a melting pool 3 and a forehearth 4 in sequence. The bottom of the feeding tank and the bottom of the homogenizing tank are connected through a first flow channel 7 . The bottom of the homogenizing tank and the bottom of the melting tank are connected through the second flow channel 8 . One end of the forehearth communicates with the melting pool, and the other end is closed. The lower part of the material channel is provided with a material outlet. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com