Device and method for preparing foam resin microspheres for physical sensitization of emulsified explosives

A foaming resin and emulsion explosive technology, which is applied in the field of foaming resin microspheres for physical sensitization of emulsion explosives, can solve problems such as product bonding, poor production environment, and low production efficiency, so as to improve measurement accuracy and prevent material breakage Conveying and ensuring the effect of heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

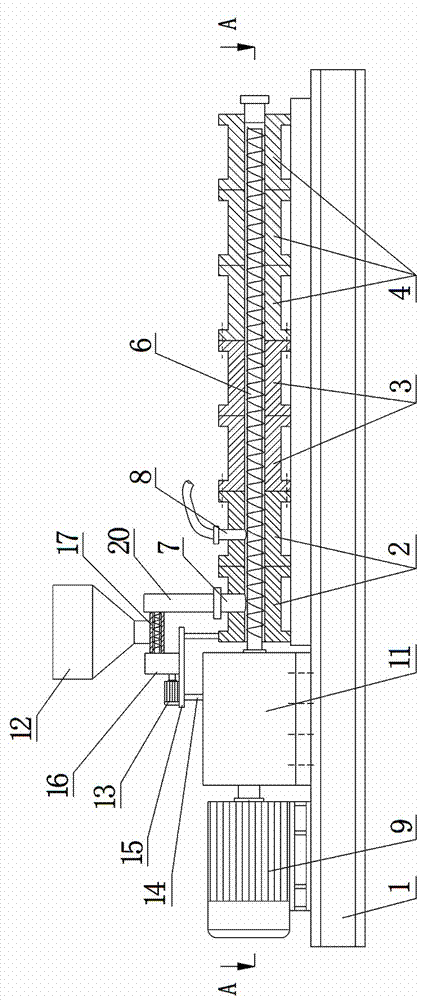

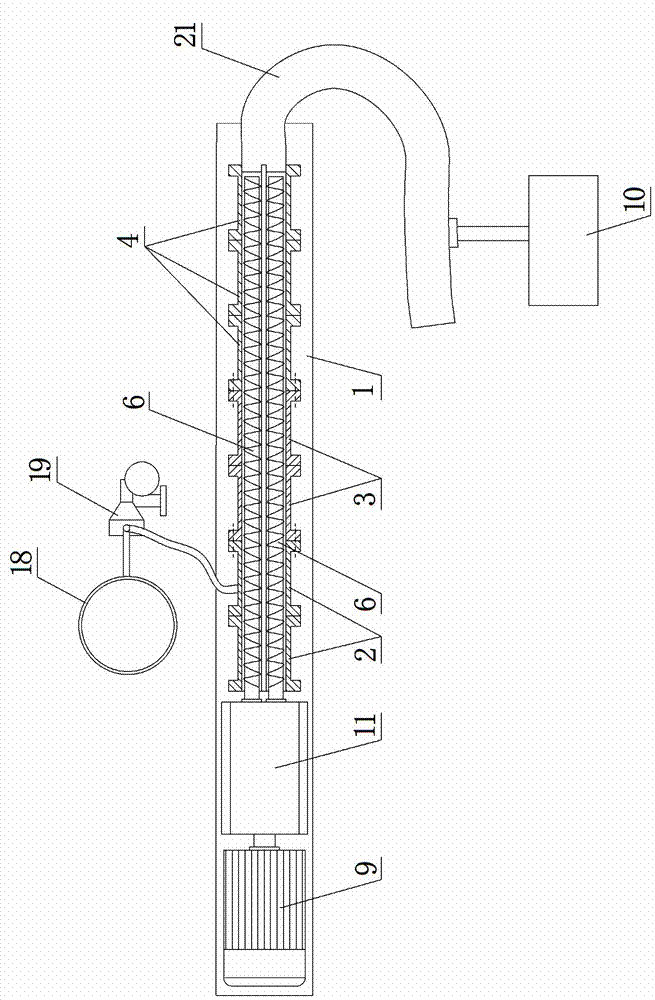

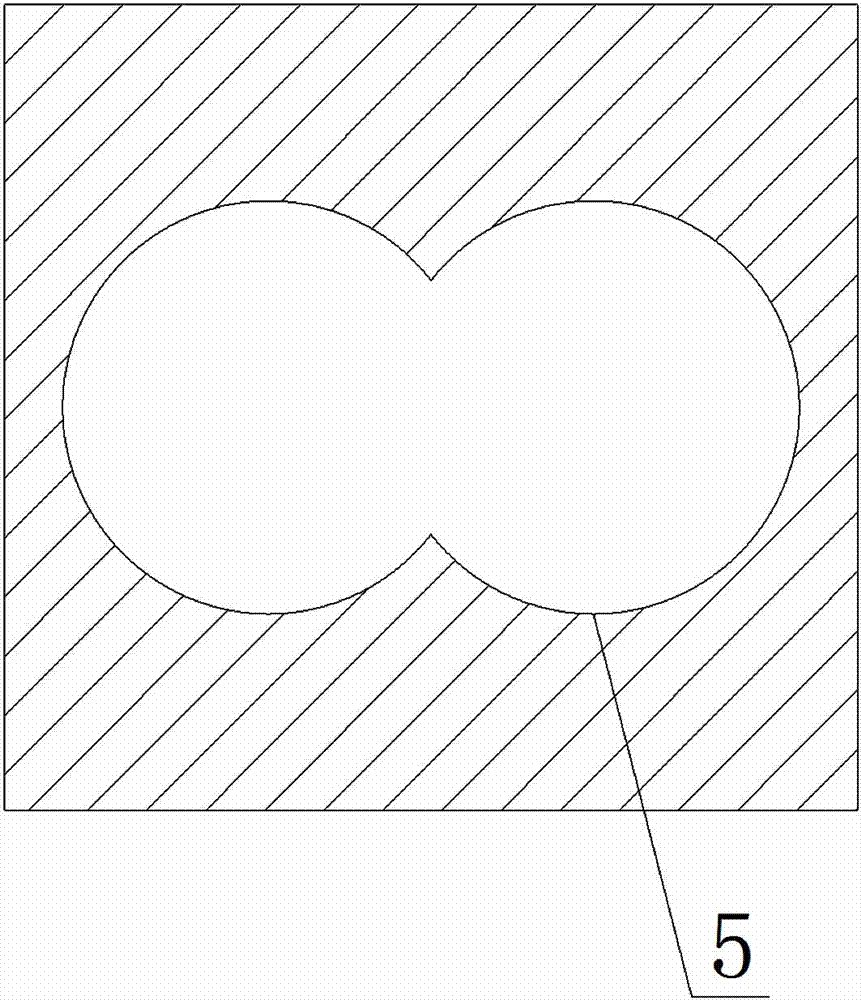

[0024] Embodiment one: if Figure 1-3 As shown, a device for preparing foamed resin microspheres for physical sensitization of emulsified explosives includes a frame 1, a temperature control device and a feeding channel cylinder, and the feeding channel cylinder is composed of feeding channels connected by flanges in sequence. The cylinder section 2, the mixing cylinder section 3 and the foaming cylinder section 4 for foaming resin microspheres are composed. The feeding cylinder section 2, the mixing cylinder section 3 and the foaming cylinder section 4 are all heated by cast copper heaters, and the cast copper The heater is connected to the temperature control device, and a material channel 5 is arranged in the cylinder body of the material conveying channel, and the cross section of the material channel 5 is composed of two intersecting circles, and two intermeshing screw rods 6 are arranged in the material channel 5, The top of the feeding barrel section 2 is provided with ...

Embodiment 2

[0034] Embodiment 2: S1, pre-add resin microspheres in the feeding bin 12, add additives in the stainless steel barrel 18, and the additives are paraffin;

[0035] S2, the addition of resin microspheres, start the motor II13, the output torque of the motor II13 is decelerated by the reduction box II16 to drive the double-screw delivery device 17 to start, and the resin microspheres in the feeding bin 12 fall into the double-screw delivery device 17 , the double-screw feeding device 17 enters the resin microspheres into the feedway 5 through the feed port A7, thereby realizing the addition of the resin microspheres;

[0036] S3, the addition of paraffin, start the plunger type metering pump 19, the plunger type metering pump 19 pumps the paraffin in the stainless steel barrel 18 into the feedway 5 through the feed port B8, and ensures that the ratio of the resin microspheres to the paraffin is 1 : 0.8, thereby realizing the addition of paraffin;

[0037] S4, the preparation of...

Embodiment 3

[0039] Embodiment 3: S1, add resin microspheres in advance in the feeding bin 12, add additives in the stainless steel barrel 18, and the additives are silicone oil;

[0040] S2, the addition of resin microspheres, start the motor II13, the output torque of the motor II13 is decelerated by the reduction box II16 to drive the double-screw delivery device 17 to start, and the resin microspheres in the feeding bin 12 fall into the double-screw delivery device 17 , the double-screw feeding device 17 enters the resin microspheres into the feedway 5 through the feed port A7, thereby realizing the addition of the resin microspheres;

[0041] S3, the addition of silicone oil, start the plunger type metering pump 19, the plunger type metering pump 19 will pump the silicone oil in the stainless steel barrel 18 into the feedway 5 through the feed port B8, and ensure that the ratio of the resin microspheres to the silicone oil is 1 : 1, thus realizing the addition of silicone oil;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com