Integrated gas supply equipment for LNG

An integrated, equipment technology, applied in mechanical equipment, equipment discharged from pressure vessels, fixed-capacity gas storage tanks, etc., can solve problems such as potential safety hazards, affecting the normal supply of LNG, and increasing the size of Small, easy to assemble and repair, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

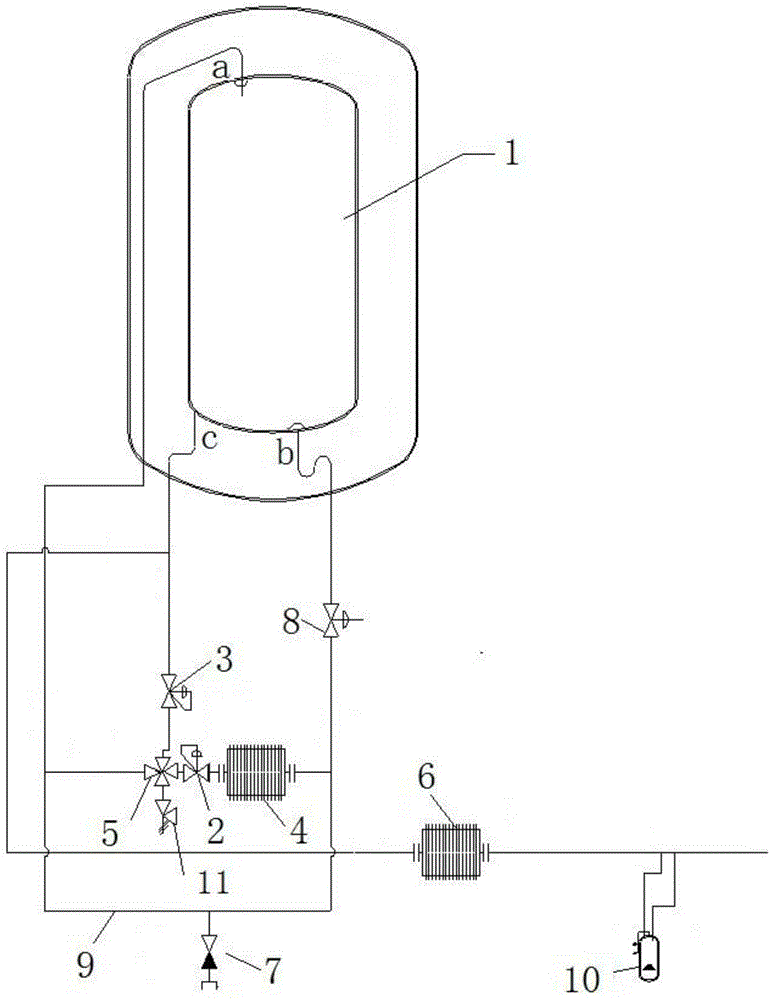

[0017] Embodiment 1: A kind of LNG integrated gas supply equipment, its structure is as follows figure 1 Shown: includes LNG storage tank 1, the bottom of the LNG storage tank 1 is connected with the first vaporizer 4, the low-temperature pressure boost regulating valve 2, and the four-way valve 5 through the pipeline in sequence, and the four-way valve 5 is connected with the LNG storage tank through the pipeline. The top of the tank 1 is connected; the bottom of the LNG storage tank 1 is also connected to the low-temperature decompression regulating valve 3 through a pipeline, and the other end of the low-temperature decompression regulating valve 3 is connected to the four-way valve 5 through a pipeline; The pipeline between the pressure-reducing regulating valve 3 and the LNG storage tank 1 is also connected to the second vaporizer 6, and the gas outlet end of the second vaporizer 6 is connected to the user terminal through the pipeline.

[0018] An odorizing device 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com