System and method for multi-layer protection monitoring and emergency support of steel structure in splash zone

A steel structure and splash zone technology, applied in the field of steel structure multi-layer protection system, can solve the problems of lack, failure emergency safeguard measures, lack of inspection methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

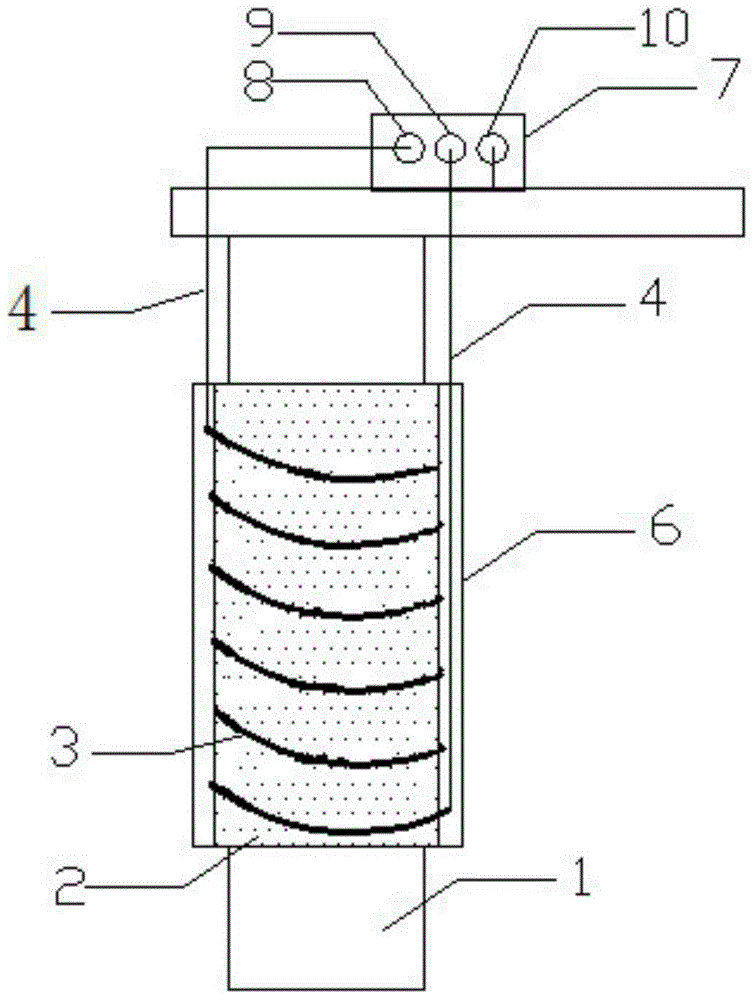

[0029] Such as figure 1 As shown, the anticorrosion layer 2 is coated or bound on the steel structure 1 first, then the spiral sacrificial anode 3 is wound outside the anticorrosion layer 2, and the wires 4 and Wire 5, and then install protective shell 6 in the splash protection area, and the end sealing completes multi-layer protection. Weld the terminal box 7 on the upper part of the platform structure, connect the two ends of the sacrificial anode to the wire 4, one end of which is connected to the first terminal 8, the other end to the second terminal 9, and the third terminal 10 is directly connected to The steel structure body 1 is electrically connected.

[0030] During normal use, the first terminal 8, the second terminal 9 and the third terminal 10 are connected by wires to realize the electrical connection between the sacrificial anode 3 and the steel structure 1. When the multi-layer protection is damaged to the anticorrosion layer 2 When , the sacrificial anode 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com