Novel diatom ooze material and construction process thereof

A construction process and diatom mud technology, applied in the field of diatom mud decoration, can solve the problems of too simple color texture, no moisture absorption and desorption and adsorption of formaldehyde, and high price, so as to solve decoration pollution, improve convenience and practicability, and reduce price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] The raw materials involved in the present invention are commercially available products;

[0012] The novel diatom mud material of the present invention is made up of diatomite, titanium dioxide, kaolin, VAE rubber powder, HPMC, nano-silver antibacterial agent, defoamer and wetting agent, and its weight volume percentage: diatom 50%, titanium White powder 15%, kaolin 16.6%, VAE rubber powder 15%, HPMC 1%, nano-silver antibacterial agent 2%, defoamer 0.3%, wetting agent 0.1%; the above raw materials are fully crushed and stirred to make finished materials.

[0013] The novel diatom mud material of the present invention comprises the following construction techniques:

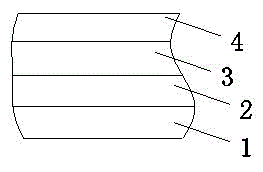

[0014] The above-mentioned finished diatom mud material is directly sprayed, rolled and brushed on the basis of the interior wall putty 1, which not only improves the convenience and practicality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com