Assembled bumper display stand

A technology for automobile bumpers and display racks, applied in the field of automobile bumper display racks, which can solve problems such as large floor area, impact on logistics flow, and tight warehouse space, and achieve low production costs, ensure inventory logistics, and simple composition and structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

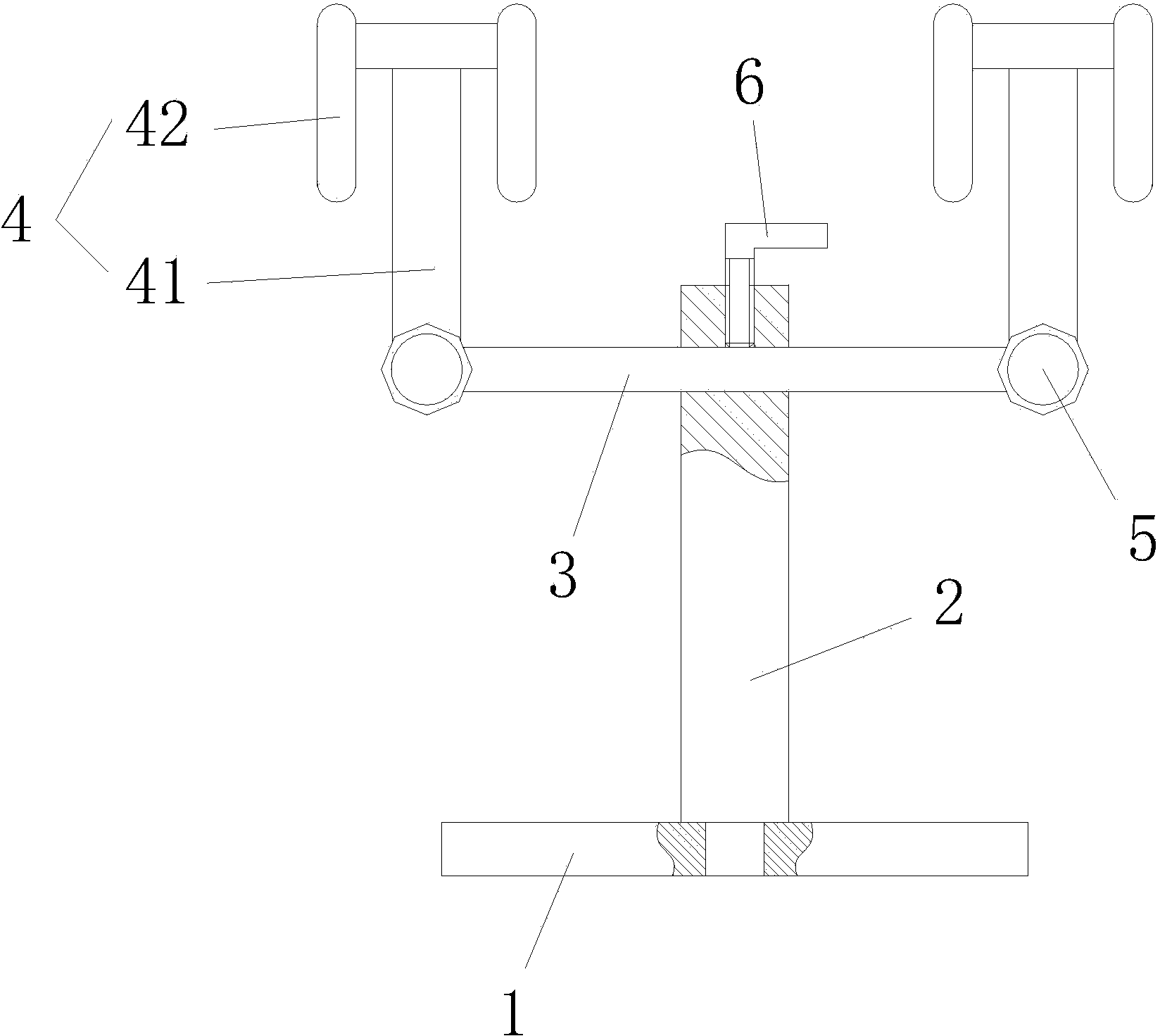

[0017] As shown in the figure, the assembled car bumper display rack includes a base plate 1, a vertical pole 2 fixed vertically on the bottom, a square crossbar 3 horizontally fixed on the vertical pole, and a bracket 4 fixed on the square crossbar;

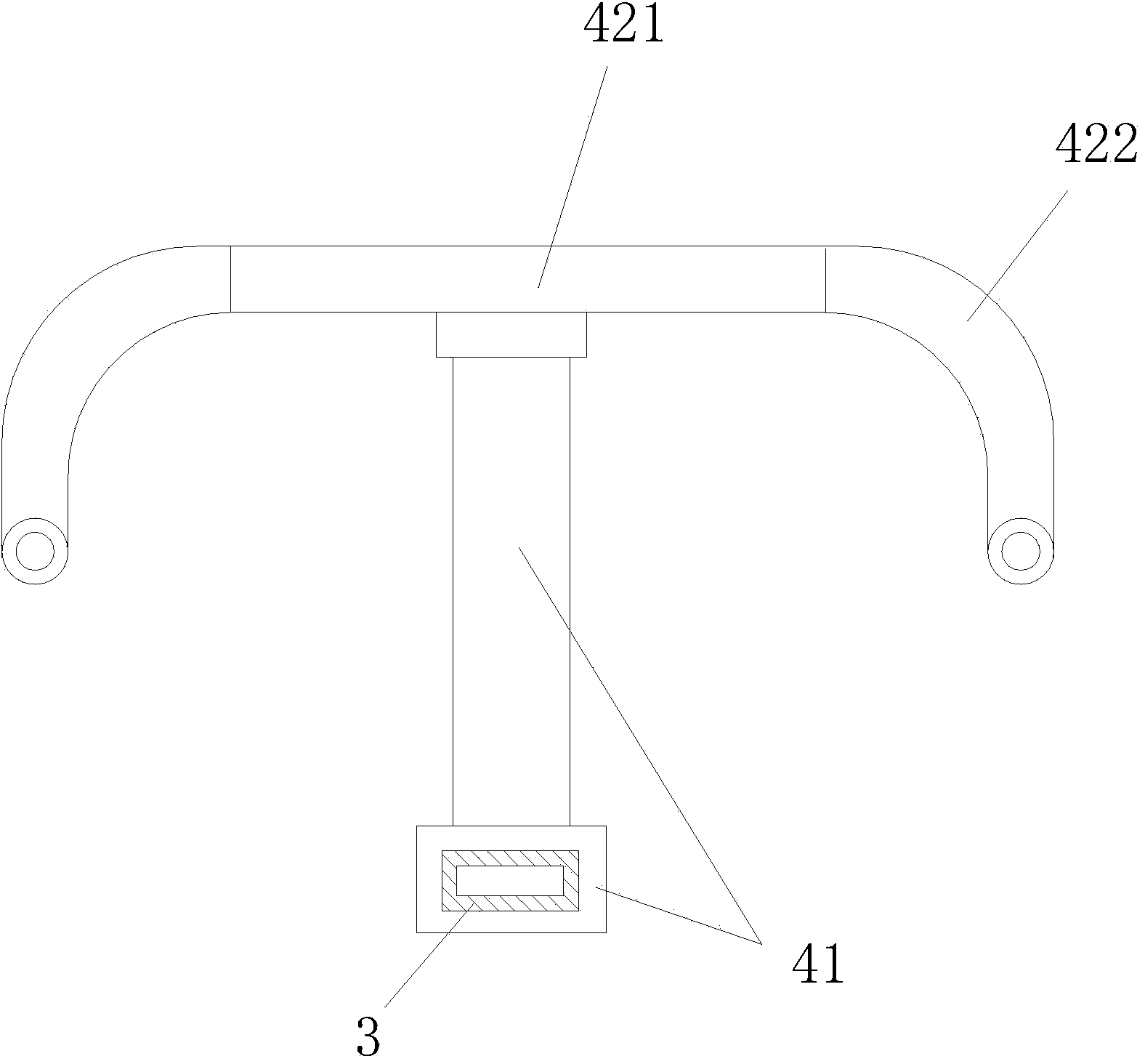

[0018] The bracket 4 includes a T-shaped support 41 and a bumper fixing rod 42 arranged on the T-shaped support. The lower end of the T-shaped support is provided with a square hole that is slidably matched with the square cross bar 3. The square hole The first locking handle 5 for fixing the T-shaped support on the square cross bar is provided on the wall of the hole.

[0019] The assembled car bumper display rack of this embodiment, its bottom plate, vertical rod, square cross bar and support can be disassembled, so that when the display rack is not in use, all the bottom plate, vertical rod, square cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com