Train pulling platform operation control system

A technology of operation control and pulling platform, which is applied in the direction of turntable/moving platform, locomotive, transportation and packaging. And the effect of high stability, correct alignment and good efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

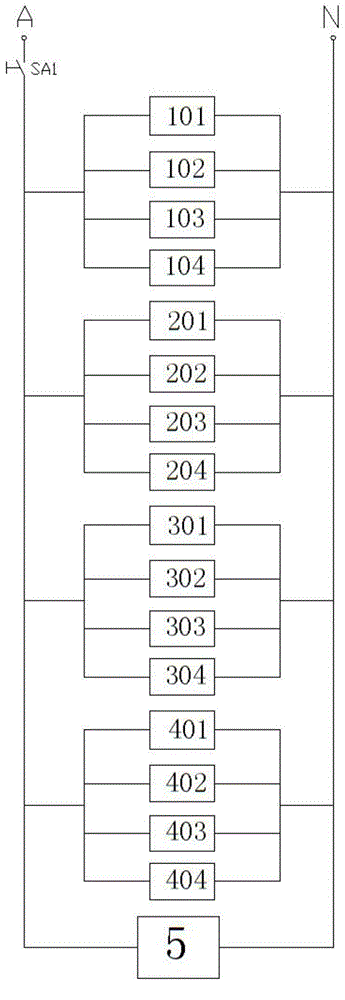

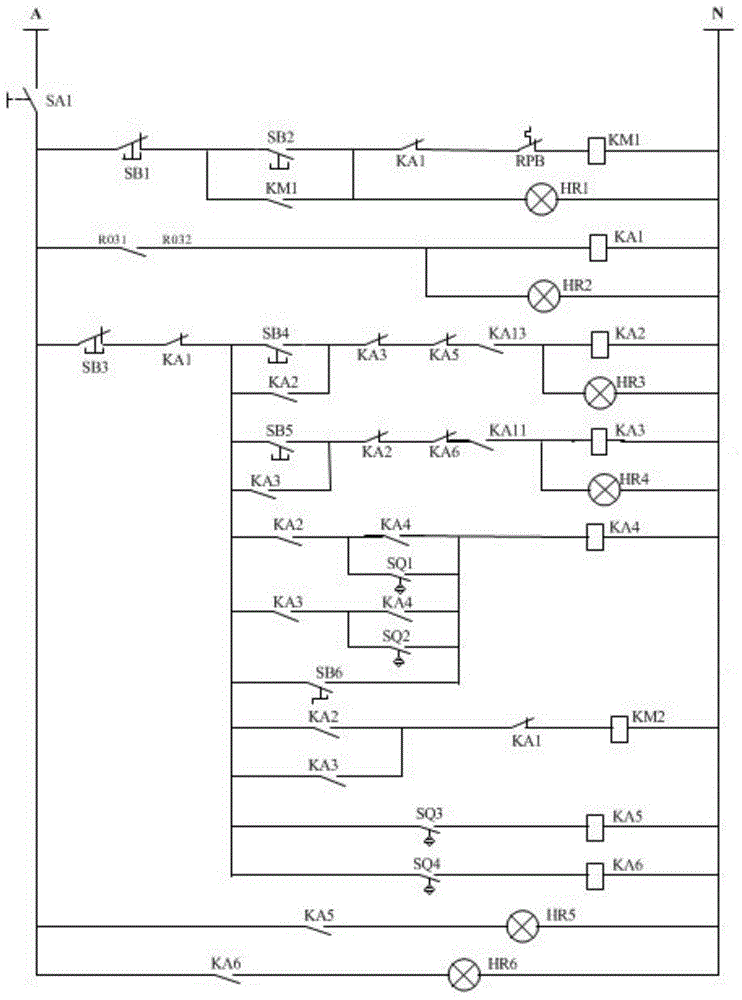

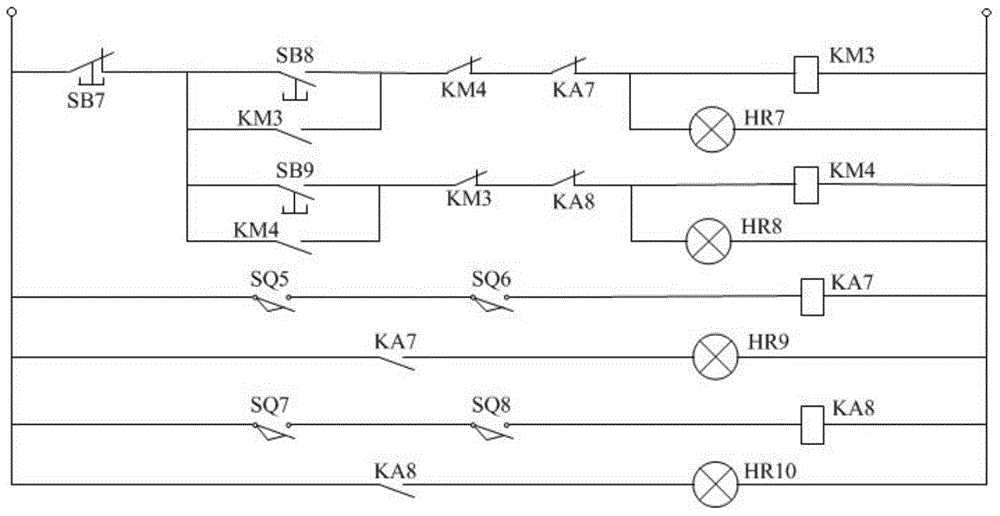

[0024] Such as Figure 1 to Figure 10 The shown operation control system of a tow truck includes a tow truck travel control module 1, a stopper control module 2, a pusher control module 3, an empty line backstop control module 4 and a wagon identification module 5; The walking control module 1 of the towing platform, the stopper control module 2, the pusher control module 3, the empty car line backstop control module 4 and the wagon identification module 5 are respectively connected in parallel, and the front end is connected to the live line A through the switch SA1, The rear end is connected to the zero line N, and the tractor walking control module 1 is composed of a frequency converter power-on circuit 101, a frequency converter fault circuit 102, a traction line control circuit 103 and an indication circuit 104 respectively. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com