Heavy-load precision redundant three-arm mechanical hand based on traveling crane

A technology of manipulators and grasping manipulators, which is applied in the direction of manipulators, program-controlled manipulators, claw arms, etc., can solve the problems of reducing workers' processing time, not guaranteeing personal safety, reducing production efficiency, etc., to reduce production costs and safety accidents Incidence rate, solving the contradiction between heavy load and precision, and improving the effect of workshop production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

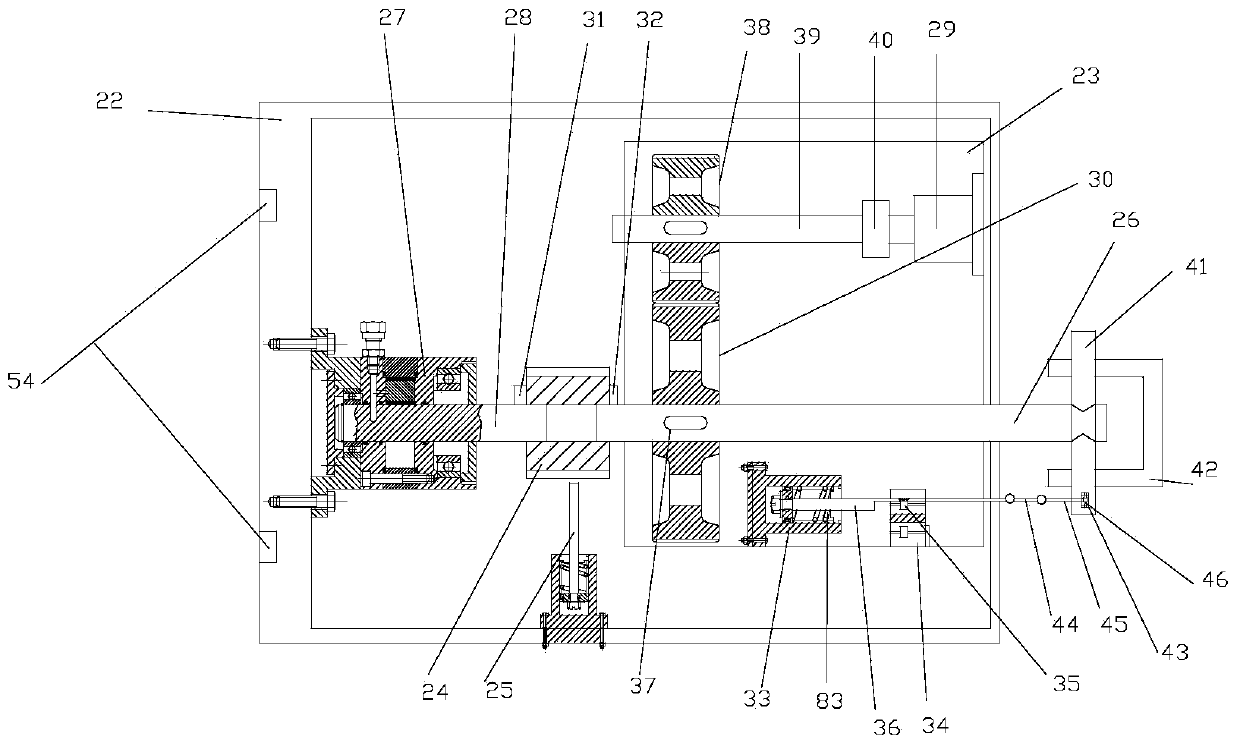

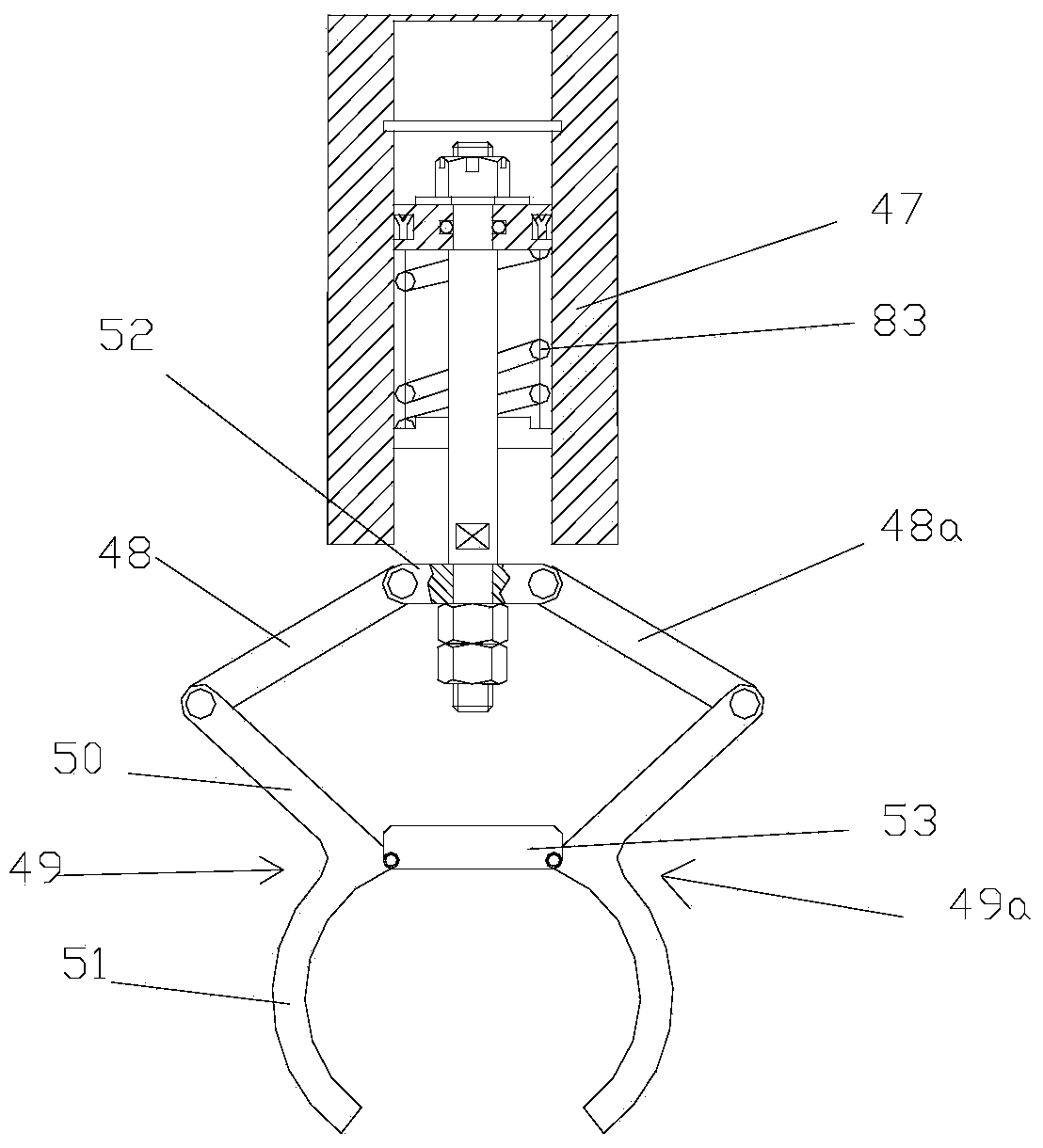

[0048] As shown in the figure: the crane-based heavy-duty precision redundant three-arm manipulator of this embodiment includes a base 1, a fixture assembly and an automatic control system. The fixture assembly includes a mounting seat 2 for installing the robotic arm. A grabbing manipulator for grabbing workpieces and a handling manipulator C for handling the grabbed workpieces. The grabbing manipulator includes a heavy-duty manipulator A for grabbing heavy-duty workpieces and a light-duty manipulator B for grabbing light and precise workpieces;

[0049] Heavy-duty manipulator A includes upper arm I3, middle arm I4, lower arm I5 and claw assembly I6. The upper end of upper arm I3 is hinged with mounting base 2 to form a shoulder joint I7 with a single degree of freedom. Both ends of middle arm I4 are connected to upper arm I3 and lower arm respectively. I5 single-degree-of-freedom articulation forms an elbow joint I8, and the lower arm I5 is connected with the claw assembly I6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com